Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

12/10 12/10 |

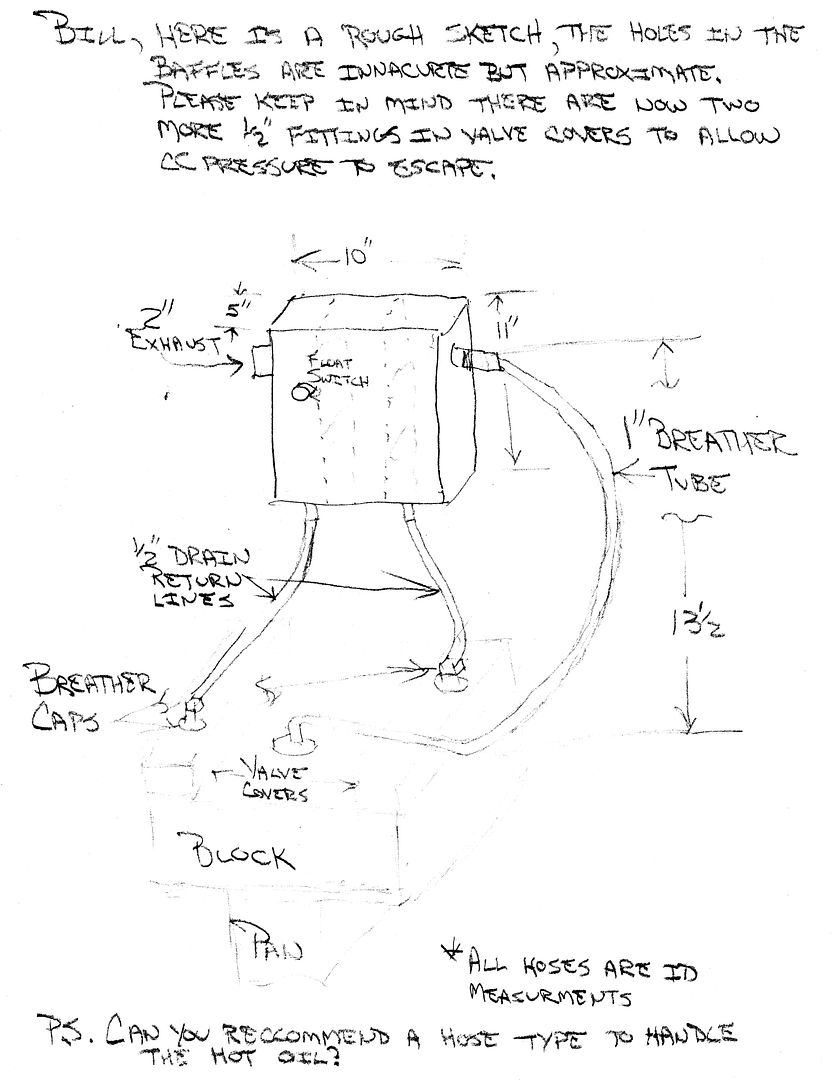

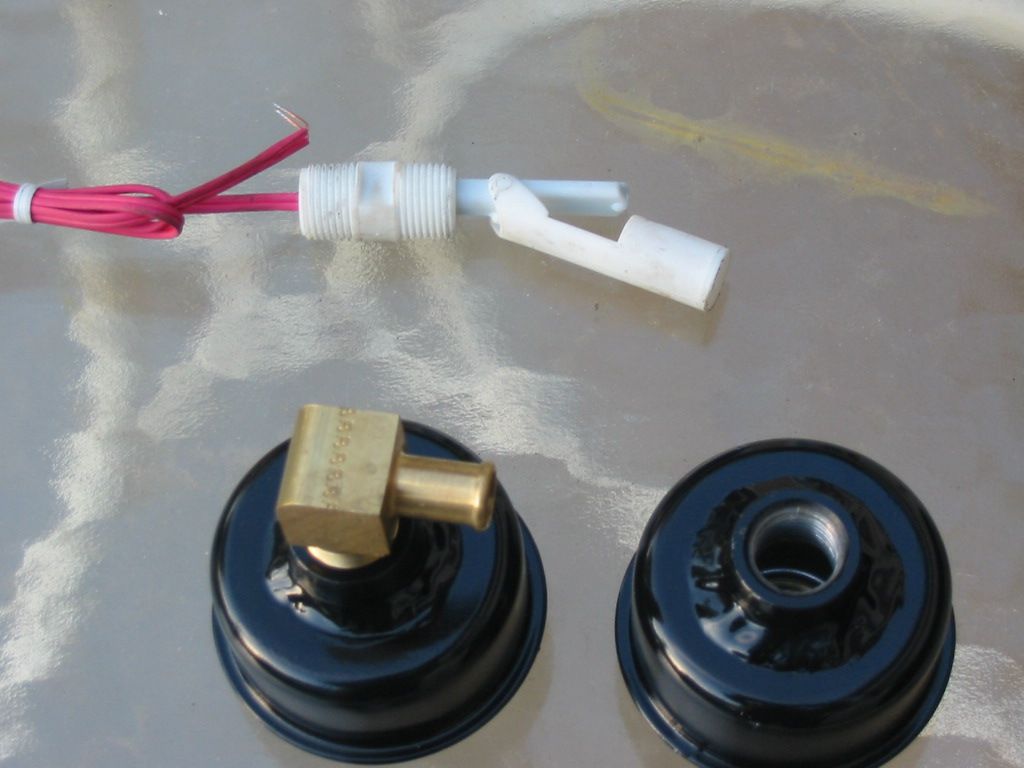

I know some of you are firmilliar with the problem I have been having with our Regency blowing oil out of the slobber/breather tube... Here are some photos of the progress so far... This is the installed tank, viewed from the passenger side...  This is a view of the exhaust from the tank on the drivers side of coach..  Here is a view of the installed tank from above, taken in the bedroom....  Theese are the modifed breather elements that go into the valve covers and will allow oil back into the crankcase.... Also the float switch that will alert me (at the drivers seat) if the tank has approx. one gallon of oil in it..  This is some wood we cut up in our spare time while playing with the Barth yesterday...  And here is Cloudy cooking up some burgers after all the hard work...  Now all I have to do is find some oil proof hosing to plumb it all in... | ||

|

|

Is that your new toad in the driveway? train JKB 88 28' Regal 454 Blue/Silver metalflake | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Well, that explains what these images are.    They've been sitting in the upload site for a few weeks and I was trying to figure it out.

| |||||||||||||||

| ||||||||||||||||

12/10 12/10 |

Yup, that was me.... Thats what the leak repairs looked like after pressure testing the tank welds, and before I ground them back down.... I was showing them to a couple people in the chat-room..... Hey Bill, can you reccomend a hose type that will withstand oil at engine temps.? I'd hate to see the hoses deteriorate and wind up going back into the crankcase, and/or leaking... | |||

|

Dare I say anything regarding the relationship between the welds and the red boxes in the background? #1 29' 1977parted out and still alive in Barths all over the USA | ||||

|

"Host" of Barthmobile.com 1/19 1/19 |

My issue with this setup is the relationship to length of hose, height of box, volume of oil... The problem I see is that all of these translate into pressure keeping the oil trapped and possibly blowing out a seal or 2. As you know, the oil will escape from somewhere. Right now there is no psi and it comes out of the crankcase breather. With the addition of this device pushing the oil uphill, and up to a gallon of oil being trapped. Might the added volume of all of this cause it to blow a main seal, or some other seal, to leak? Do me a favor, draw out on a piece of paper how the lines, vents, switch, breather setup are supposed to go. I would like to see how you are envisioning this setup. I would just hate to see a bigger problem then what you're trying to overcome.

| |||||||||||||||

| ||||||||||||||||

12/10 12/10 |

| |||

|

"Host" of Barthmobile.com 1/19 1/19 |

1/2" drain lines should be a hydraulic type of hose. I would recommend a power steering return line like a NAPA - NPS 76186 The 1" supply line you might have to go to a hydraulic store for that. That should never kink and the rigidness of a hydraulic line might be what you're after. I still have a problem with this setup for the same reason I stated earlier. You're pushing too much gravity. The length of the 1" hose isn't just upward, you also have horizontal push. What psi do you need to have to push this up and into the collection box? If you had a collection box that took the oil from a lower point and pumped it into the valve cover, that would work alot better. Not an ideal situation, but still better on the seals. Might a 30 second run timer on a float activated switch work better? Not really an ideal situation but I understand why.

| |||||||||||||||

| ||||||||||||||||

12/10 12/10 |

Actually I had thought of that but was concerened about a possible mechanical failure (sw., pump, batt.) and opted for the tried and true method of a gravity engine.... That hose (breather) going into the tank is no higher then it was when I bought the Barth (remember how it was "tied" pointing up?) plus it now has two other 1/2" hoses to release CC pressure... "IF" it works anywhere near what I'm hoping for the float switch (emergency indicator) should never activate... Thanks for the tip on hoses.... Keep your fingers crossed and I'll report back in after a test run... | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Good Luck on your test run Patch, I hope it works.

| |||||||||||||||

| ||||||||||||||||

| First Month Member |

Nice float switch. Who sells it?  Nice woodpile. Can your mice or rats climb up the side of concrete blocks? I lost a schnauzer to the black widows in the woodpile because she was always after rats there. I went to steel legs with plastic pipe around them to keep the rodents out. . 84 30T PeeThirty-Something, 502 powered | |||

|

| First Month Member |

Disclaimer: the following is just drivel from someone who knows nothing about diesels. But some of it may apply. I think the up line is good, because mostly oil-laden air is going upward, and the oil will have a chance to condense out and run downward. It's not like crankcase pressure is trying to push a full column of oil upward. The early Ducati bevel single racers used a 1" ID clear vinyl tube going up from the crankcase to the top rail, then back a couple of feet. You could see the oil drops forming on the ID and then running back down. Armchair observers commented that that large a diameter was overkill for such a small engine. Taglioni knew what he was doing. In my book, that man walked on water, but I digress. I stuck a little piece of copper kitchen scrubber just at the top of the vertical section to condense any oil vapors. Very little oil came out the rear, even under racing conditions. Early Norton twins used crankcase vent oil to lube the chain, even. I would adjust the amount of chain lube applied by adjusting the height of the vertical column. I raced on Sunday, so the long tube was installed to avoid over-oiling at high revs and lots of throttle. For trips or commuting, the shorter tube was used to be sure a little oil got on the chain. In a similar fashion, some puke can setups use a "coalescer" in a vertical section of line to cause oil droplets to form and run down. When I made a puke setup for a rumpity-rump boat, I measured the pressure with a manometer to make sure the outlet was big enough. I ended up with a vertical outlet with some really coarse industrial stainless steel scrubbing bat loosely held in there to coalesce any remaining oil fog. Later, I dispensed with that and just put some loose scrubby inside the puke can. That seemed to catch the oil vapor before it could be expelled into the outlet. In your case, with limited vertical clearance, either the SS in the can or a scrubby pad coalescer in the horizontal line with a little drainback to the valve pans would probably work, if necessary. The amount of oil in the outlet will tell you. Again, check the can pressure during a long hot hillclimb to be sure. Aim for as low a pressure as you can. Jeg's sells a unit, but it could be too small for your use. . 84 30T PeeThirty-Something, 502 powered | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

To give you a little bit of a backstory Bill... We saw his coach at the Milford, Indiana GTG and looked for an oil leak then, none was found when running. I commented on the fact that he might have too much crankcase psi and it could have forced the oil out of the dipstick tube. I cautioned about "Tying Down" the dipstick tube because I was afraid that he would blow out all of his seals. On his trip back home he lost alot of oil again and this time he did see that it blew out from there but he thought that maybe it was because of a bad dipstick. After replacing the dipstick it did it again. Patch is trying to overcome very heavy blowby under a load. He lost almost all of his oil, in a very short distance, from when it first blew out. Here is his post on what happened. He even made up a manometer to test it out. I was afraid that the volume of oil he lost in such a small period of time, he described it as seconds, might force a main seal to blow out. Motoroil, sitting in a 1" hose as a backstop, trying to overcome gravity, or a kink in the line, might cause a problem. It's been awhile since I've worked on an 8.2DD but I believe the crankcase vent on this engine sits inside of the valley between the heads. In this scenario he's right that it only has a few inches to push up. The picture shows what looks like a long sweep of hose. That equals to a volume of oil that could slow down the venting enough to blow out somewhere else. I forgot, but he's right, he did have his blowby tube facing upwards when I looked at it in Milford and it didn't blow out a seal then so he could be ok. I just wanted a more detailed drawing of his intentions to bat around. PSI = force and the 2 drain tubes going back to the valve cover would still be under PSI from inside of the valve cover. The oil can't gravity feed down if it's under psi so he's using a float switch to tell him his oil can is full. At this point I assume he would need to shut off the engine, or lay off the throttle 100%, to let the oil drain back down. This is why I thought an oil pump under PSI could work better. Maybe lowering the catch can could help too? Of course, the proper course would be to rebuild/replace the engine... But, money is tight all over. So I said... Hope it works out for you Patch.

| |||||||||||||||

| ||||||||||||||||

| First Month Member |

WOW! That is a lot of blow by. Far beyond the normal puke can situation. I will stay out of diesel talk. . 84 30T PeeThirty-Something, 502 powered | |||

|

12/10 12/10 |

Yes and no.... I do think that the oil could still flow downward (gravity) even though there is CC pressure pushing up (even at the same time) Also I think the two drain/return lines (the 1/2") will do the same as the breather tube.... The float switch is hopefully no more then an emergency notification that the oil has overcome the force of gravity and is building up in the tank at which point I assume all I would need to do is get out of the turbo (hopefully)... It dosent spit ANY oil until I get into the turbo.. I did buy the hose today... Got the 1/2" at NAPA ($4 a foot)(TY) and found a suction-hydraulic (wont collapse or kink) 1" line at another specialty shop for $0.78 an inch (ouch) but I bought 40" and I am sure I will need to cut it down after looking it over in the Barth... I still think it will be less pressure in the breather tube then the way it was... | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.