Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

4/10 4/10 |

I have an ongoing problem with the air system on this coach and am posting this in the hopes that someone might have an idea (ANY idea) of what I should have checked to resolve what has developed into a very expensive and frustrating beyond imagination issue. Please bear with me as I will attempt to reconstruct the history to the best of my recollection. There are many side stories about all these breakdowns that I'll try to omit. The result of the problem (that has not yet been identified after 1 year) is blown head gasket(s) on the air compressor. When I first bought the coach in April 2007 it had a blown head gasket on the air compressor. I discovered it by hearing an air leak in the engine compartment area after I would shut down and felt the air coming from the head of the compressor. The coach did build and hold air while running as far as I was aware, but I had to be on the road to NY the next day, so it was repaired at a Freightshaker shop that night (expensive). This repair lasted until the current problems (over 20K miles) and 2 full years. April 2009: Went WI to Buffalo NY to WI and on the way back stopped in Indiana for a couple hours (to miss morning rush hour in Chicago) and then started out, going thru the last toll in Indiana noticed the air pressure dropping and was able to pull into last service plaza in Indiana before the brakes locked. First Guess: Govenor defective (this diagnosis was abandoned when they thought the govenor was built into the head of compressor and disovered that it wasn't). These guys never did find the govenor. Diagnosis: Air compressor defective. Solution: Replace air compressor (only available a/c found in ND $2500). We ended up finding a shop that could rebuild the original and had all the parts available, took 2 days. I now believe that this was misdiagnosed and was only a blown head gasket. The coach wasn't used for any substantial milage until: September 2009: WI to Chicago to WI lost air pressure every 2-3min (125psi-100psi-125psi) rear or primary air only. When I took it to repair facility it was losing air as soon as it was at 125psi air compressor was running continuosly. Diagnosis: Defective air dryer and check valve. October 2009: WI to Washington DC to Ohio (Pittsburg area) air pressure was still dropping every 6-7minutes. Then left OH to WI and pressure was gradually worsening to every 2-3minutes until after passing thru the last toll plaza in OH it was no longer building air; 2am brokedown. Diagnosis: Air compressor head gasket. Solution: Aired up coach from external source and it held air to a repair shop. This shop could not repair but lined up a shop that could do it in the morning. Truck chaser followed to the me to the shop and aired up twice in 30 miles. 2nd Diagnosis: The next shop wasn't going to just replace the gasket until they found the reason for the gasket to blow. They found a twisted main discharge airline (really twisted) and attributed the problem to this. Found a gasket an hour away. After repair I still lost air every 6-8 minutes but I decided to rollout to WI without any further troubleshooting (it was sundown). November (early) 2009: I had dropped the coach off to replace the front oil hubs, front brake canisters and pads (one can was really weak and I had a brake drag which produced enough heat to cause the hub seal to leak. I also wanted the air leak problem resolved. Diagnosis: Leak not located, but the govenor was finally found buried under ailines, wire cables, etc. and it was reasoned that if defective it could be the problem so I had it replaced ($30 part, why not replace it). Still leaked air (oh well). We could hear a hissing in the air compressor area sprayed some suds around annnnnnnnnnnnnnnnnnnnd IT'S THE AIR COMPRESSOR GASKET AGAIN! sorry for screaming. It was guessed that with all the problems it was caused by a warped head. Solution: I have to leave the next day for Buffalo NY no excuses!! I was supposed to have left that afternoon. We located a new compressor in Wausau WI (3hrs away) that could be had for the low price of about $1500 w/core but would not be available until morning at 8am. I was there at 8 and brought it to the shop but the gaskets were not included with the compressor so we located those 2hrs away. When we got the gaskets the main gasket was the wrong one so I took gasket material and cut my own. The new compressor came with a relief pop-off valve on the head so hopefully this would prohibit the gasket blowing from pressure building up if there was a blockage in the system. This was another misdiagnosis (in my opinion) I don't believe that the original air compressor head was warped. November 2009: WI to NY the air system was still leaking down air every 12-15minutes. Prepared to leave NY to WI and the coach WOULD NOT AIR UP. There was a valve located under where the house battery is that was blowing air out (this valve had done that once before when it was -20 degrees and stopped on it's own) I tapped it but it still leaked. I then tried to start and air it up again but this time I held the engine at 1800-1900rpm and discovered that it was building air (and the valve was no longer leaking). I decided to gamble and leave to WI (it's 10pm and I am not in a place I could stay anyway). Non-stop to WI, I never shut it down until I got back, and the air was dropping every 6-7min. Took it back to shop. November (mid) 2009: Went to pickup coach at shop after they "located" leak problem. I needed to be in Chicago the next day. Diagnosis: I had asked that the valve that had leaked on startup occasionally be replaced, and check for other leak problem. Solution: Replaced valve, and there was something else that was done (minor but I can't remember what) to resolve leak. I didn't make it 7mi and the air had dropped twice. I returned it to the shop and had to make alternative accomodations. Diagnosis: Rear brake can was leaking (I did have the pancakes replaced a year ago). Solution: Replaced can. December (early) 2009: WI to Des Moines IA to WI air leaked about every 15-20min on the way out and back. Parked overnight at home on the street and next morning went to move it to storage location (18 inches of snow coming the next day). THE COACH WOULD NOT AIR UP!!!!! Called shop and again aired up from external source. Once it was aired up it would lose air about every 6-7min but it did build it back up while rolling, so I was able to get it to the shop (1hr from home). I told them that I didn't need it till Mar-Apr so take the time needed to resolve this. Diagnosis: The head on the new compressor was now warped and there are a couple valves that had to be rebuilt (the valves are not available) because crud from airlines had plugged them and those lines were replaced. Milled the head flat and again replaced gasket. April 2010:So I go to pick it up annnnnnnnnnnnnnnd it loses air every 10min.............I left it at the shop. If anybody made it thru all of the above (my apologies) any troubleshooting advice would be greatly appreciated. 1990 32' Regency Spartan Chassis Cummins CTA8.3 Allison 4 speed | ||

|

12/10 12/10 |

Steve, sorry to hear about all your headaches with your Barth... I wish I knew more so I could nelp you but that is a puzzle I've never tackled... Sounds like somthing Professor Rusty or Bill N.Y. may know about... Good luck in your quest... | |||

|

Captain Doom |

Many coaches with air compressors used venturis to provide vacuum to the cruise control. Although more common with Breakaways (also on Spartan chasses); this "feature" causes a quick loss of air when the compressor (meaning the engine) is shut down. Air loss may not be abnormal. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

4/10 4/10 |

Thanks Rusty, I will ask about the cruise control, I have never used it. After rereading my post I neglected to mention that the coach would lose most of the air when shut down until I think it was after the September repairs, then it would not lose air or only very little air for days when parked. Because it would at that point hold air better than a lot of air systems when parked, but continually lose air when running we checked for leaks with the service brake off and the wheels chocked and still no leaks were found. The coach only loses substantial air while running. The theory is that the gasket is blowing because the compressor is overworking to keep up with the loss of air and producing too much heat (the shop claims that they monitored the temp at one point this last time and found it not to be a problem at this point) or there is a blockage and the pressure is building up to the point that it blows out the gasket. 1990 32' Regency Spartan Chassis Cummins CTA8.3 Allison 4 speed | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Things to check, things to do and things to know. ~ Always have a psi relief valve mounted in the head of the compressor. ~ Make sure you have sufficient coolant going to the compressor. Maybe what you have is blockage of coolant that is causing the head to warp. ~ Air gov cutout is set between 120-125. The compressor will build to 120/125 range and blow off at the dryer. After this it'll kick back in at 20psi less, the kick in is factory set to around 20psi less than blow off by the weight of the spring and is non adjustable. ~ Your "Brake Can", aka Maxi-Chamber, is doing double duty as a parking brake and a service side application brake. If you have a leak while applying your brakes it is probably a simple diaphragm. If it leaks when you push the button in to release the brakes, it's probably the half can as the parking spring usually pokes a hole in the back side of the diaphragm. ~ Your system will loose psi for a variety of reasons that is considered normal. Your height control valve, your cruise control and/or heater door flappers venturi vacuum generator and maybe even your wipers use air on a regular basis. When you use the brakes it take psi out of the system. ~ A restricted air dryer can also cause a blown head gasket but if you have a psi relief valve in the head that will not happen. ~ The line from the compressor to the dryer needs to be in a straight line going downhill. If the compressor discharge line droops, water will hang out there and when you start it up in freezing temps it will blow something out if you don't have a psi relief valve in the compressor head. Send me a PM with your home number and I'll give you a call.

| |||||||||||||||

| ||||||||||||||||

1/09 1/09 |

well read ur post hope u solve the problem! | |||

|

You said it only loses air when being driven. This statement leads me to believe you have a major air leak in your air suspension system. So a couple of questions. When you stop does it maintain height? Do you use the air to level the coach? Do you have a HWH air leveling system? If you have the HWH system I will add more. '92 Barth Breakaway - 30' 5.9 Cummins (6B) 300+ HP 2000 Allison Front entrance | ||||

|

1/11 1/11 |

How are your brake lines? Sounds like it leeks down when driving and using brakes could be brake cylinders or line connections.Do you keep your pac brake on?Could leak when taking your foot off of the accelerator.When taking your foot off the accelerator the PAC BRAKE valve would be wide open every time. lenny PS same model and spartan with a 8.3 lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

4/10 4/10 |

I have an HWH leveling system but it's hydraulic, not air. The system does have an "air dump" but I haven't used it and when checking it no leaks were found. I have loosened up my pacbrake 3 times in the past from being frozen and because it freezes up after each time I have given up on it, so it is not turned on any longer. We have checked this area for leaks and found it all to be air tight. Thank you for the suggestions, it's all greatly appreciated. I will check both these areas again though. 1990 32' Regency Spartan Chassis Cummins CTA8.3 Allison 4 speed | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

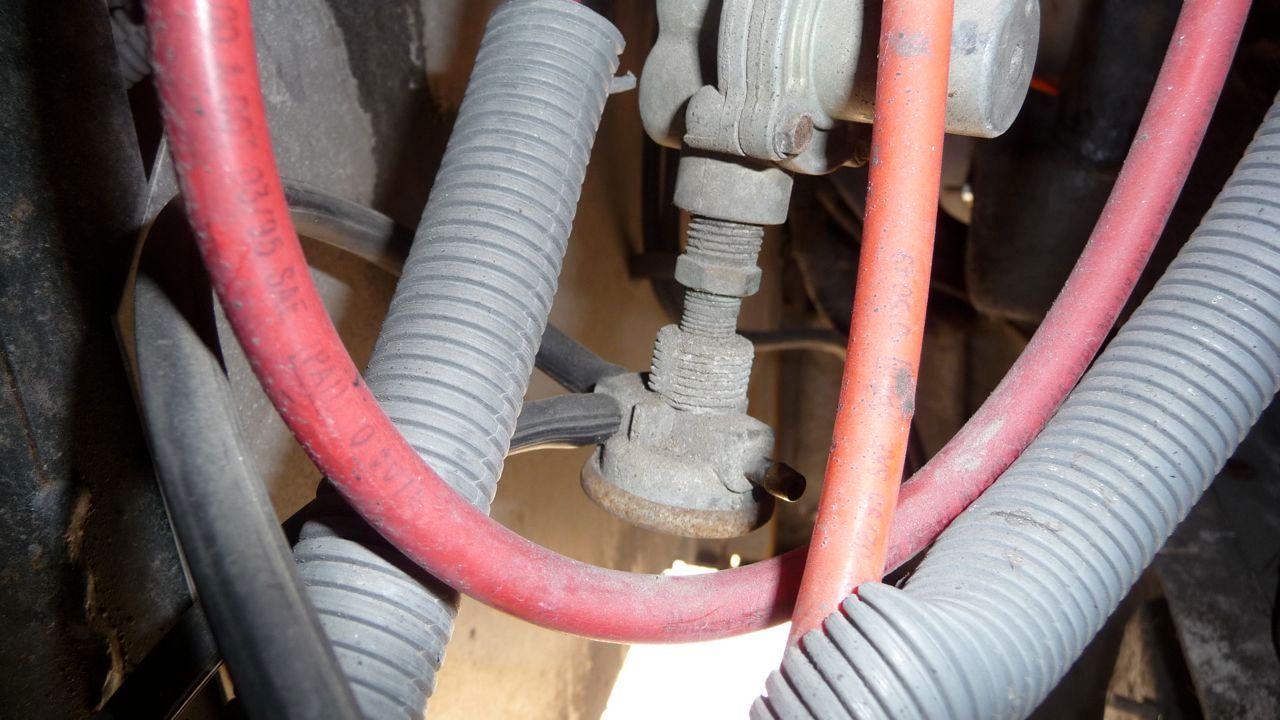

Click here to understand what a vacuum generator is Here is what a vacuum generator looks like.    If your air leak is because of this, you might want to do what Ed did. Vacuum System Redesign

| |||||||||||||||

| ||||||||||||||||

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.