Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

6/12 6/12Formally known as "Humbojb"  |

The fuel supply lines on my 85 Regal,454 quadrajet, are 3/8" ID. Fuel return are 5/16" ID. That's what fits the factory fuel pump and the factory switching valve that switches from the rear fuel tank to the mid fuel tank. Is your supply line 1/2" ID? Jim

| ||||||||||||

|

|

B&H! You have good news! I am happy you are rolling. Here is what the top of my gas tank looks like:  There is one tube for the emmissions controls, one tube for gasoline suction, and one tube with the flared fitting for a gasoline return. This tube goes to a reinforced hose to a pressure regulator, which if I understand what the other guys in this community have told me, is on the return path from the mechanical fuel pump on the engine. This pressure regulator is mounted on a frame rail very close to the gas tank. I wonder if your rig is similar. Anyway, it sounds like you have a solution and it should be good for years to come. Fuel: regular is fine I guess, I am generally a sea level driver. At altitude in the west, I saw 85 octane for sale, I never saw that before. I had one very bad fillup of something that must have been overly done with ethanol, I had knocking and pinging. Next fillup as soon as I had some room in the tank was on 93 and all was well. Happy motoring! Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

Thanks olroy. I'm generally fine with cruising at 60mph. I figured that was fast enough considering it's only a 3 speed. I don't have a tach, so I'd rather err on the side of caution. Jim, my supply line is 1/2" ID. I think this was a later addition. I can just barely see the fitting coming out of the top of the tank. It looks smaller( 3/8" maybe ) and that's where the 1/2" line starts. Matt, I certainly hope this fixes it for at least a few weeks to come! Keep your fingers crossed for me please! 1986 Regal 25ft. 454 Chevy | ||||

|

Oh, and I only have one tank. 1986 Regal 25ft. 454 Chevy | ||||

|

"Host" of Barthmobile.com 1/19 1/19 |

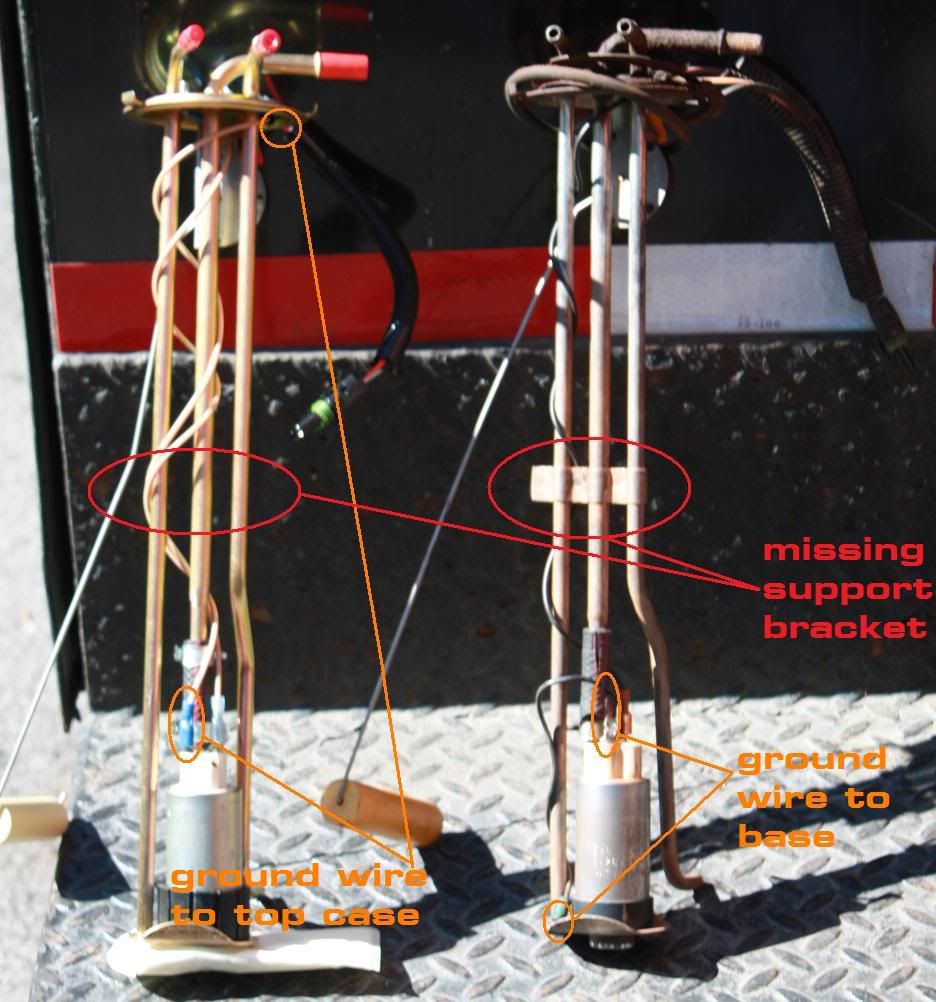

Congratulations... I hope all goes well! Do you have a separate pickup tube for the generator? My 3 tubed fuel tank sending unit had the pickup tube for the generator attached.  In these images, that compares the new sending unit w/ attached fuel pump to the replacement piece, it is the tube on the right.

| |||||||||||||||

| ||||||||||||||||

|

>Do you have a separate pickup tube for the generator? T-fitting on the rubber hose. | |||

|

I do have a separate pick up tube for the generator. I don't know where it comes out, but it runs up the driver's side to the generator. 1986 Regal 25ft. 454 Chevy | ||||

|

3/23 3/23 |

Want confusion? Starboard fuel tank supplies the genset but that pickup does not go to the bottom of the tank. Tanks can be separate or combined or one to both engines. My fuel gauge never fails, it is a calibrated 1" square stick. A friend pulled a tank and found all manner of sawdust in it. It took him a couple of minutes to figure the sawdust came from the fuel gauge. | |||

|

12/10 12/10 |

| |||

|

|

Hi, I want to report on latest findings. Like many others running the quadrajet, I have troubles with hills. I have replaced vacuum lines and distributor components. I have the 454 time at stock 4 degrees BTDC and using the ported vacuum. I'd observed that the secondaries were never opening. I checked the choke and adjusted it so that it was not a factor. The choke has a feature to disable the secondary throttle shaft from rotating. At the top of the secondaries, there are other parts I have seen referred to as "air valves" or "air doors". There is a spring which keeps this closed. This spring is a coil spring, and is around a shaft. The end of the shaft has a flat head screw, in order to adjust the tension in the spring. The shaft is prevented from rotating by a set screw with a Torx T-10 head on the 17085212 carburetor. Guys like WhoSaidTyler in his youtube videos described the "air doors" as having an ability to open with a light finger pressure. The air flow would do this when the engine is running. I thought on my case, it was more than a light finger pressure. And since I saw that this had not opened when running, I thought something else was up with my engine situation. In my work, I loosened the Torx set screw, and the spring came off the lever arm of the "air valves" shaft. This is in a very inaccessible location mechanically when the carb is on the engine, so I had to remove the top of the carb. There are many larger Torx screws here. Doing so damaged the gasket, it is called the air horn gasket I think. I need to get a new one. I have pictures I will post. I removed the metering rods that are positioned by the "air valves". I reattached the spring, and adjusted the "air doors" by positioning the screw, and tightening the set screw. I reattached the air horn, that is the upper part of the carb, with the old gasket. I thought it would be close to a miracle if the engine started, and it did. I took it for a 20 minute test drive. I heard the "howl" of the secondaries for the first time in years. I am guessing that something about the heating/cooling cycles of the engine caused that "air valve" return spring to position itself or bind up and keep the secondaries choked off. The engine was producing power at 4000 RPM and 40MPH. At about 15 minutes in the drive, the rig wanted to stall out and I was on a long slow incline. I made it up at 5MPH only by fluttering the gas pedal. I thought I was going to need a tow. But there was a series of backfires after about 3 minutes of this, and the engine roared again. I imagine that dirt or gasket debris was somewhere it should not have been. So now I am at the point where I am getting the occasional backfires out the exhaust and the intake, even though the power level is improved. I am going to try the first ideas that come to mind after reading the collective wisdom and experiences of others in this form: replace the fuel filters and check the pressure regulator. I also wanted to report on having found this website: http://cliffshighperformance.com/ Cliff is a quadrajet specialist and wrote a book on the topic. There are discussion forums on that website and 17085212 is noted there many times. Cliff notes the differences between this and other quadrajets and how the calibrations are set for the RV application when delivered stock from the factory. Does anyone have the list of factory recommendations for the 25 year service interval? Happy Motoring, Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

Official Barth Junkie |

You are a brave man to confront the elusive quadrajet. Back in my carburetor days, I liked Holleys because you could remove the float bowls and jet blocks from the side of the carb. Very easy to work on and you could usually get them to run well with minor tweaking. The quadrajet was always a hassle to work on. You have to remove the entire carb top, with associated linkages, floats and metering rods hanging down all over the place. On the other hand, the small primaries with giant secondaries gave good mileage and performance when you get them set up right. Good luck with your project! I would remove and clean the carb at this point, sounds like dirt dropped into it somewhere. I would strongly consider sending it out to one of the remaining carb wizards. They have numerous parts and jets at hand and can usually get it right the first time. Finding individual parts can be a hassle. (Actually, when I considered the cost of my quad rebuild as well as poor high altitude performance, I went with the throttle body fuel injection system. Sold the quad and never looked back.) If you are only running 4 degrees advanced you may want to try more advance. Run as much advance as you can without knocking under load. I was running 12 degrees. If you look at specs for the engines of the 60's and early 70's they all ran 8-12 degrees advanced. The smog police forced the "retarded" timing specs. (Get the carb right before you mess with timing.) Keep us posted on the q jet project! 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| First Month Member |

I like Holleys for street cars, hot rods and boats. But I have serious reservations for hot environments like RVs. The heat dries, embrittles and shrinks the gaskets, which can result in a fuel leak. Some of the metering block/float bowl gaskets are very narrow, and a little shrinkage can make a leak very easily. Even on my boats, I blocked off the heat riser passages to keep the Holleys a little cooler. And propped the doghouse open a little to let hot air out and prevent bilge fumes from doing their evil. . 84 30T PeeThirty-Something, 502 powered | |||

|

|

If I did this correctly, there are two pictures, showing the underside and the side of the airhorn. The underside shows the Torx T10 set screw, and the spring on the lever arm of the "air valve" shaft. The side shows the screw head used to rotate the shaft the spring is on. 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

|

This is the underside view. [is it possible to put two pictures in place usign the "uploader"?] 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

|

I've bought a used 17085212 Quadrajet to rebuild and try out. The q-jet is an interesting beast, it looks like a modular carb, with different throttle bodies, main castings, and top covers. The 17085212 is at the end of the non-electronic controls, and might be considered at the peak of the carburetion science and arts. Typical problems, I've read, are that the primary throttle shafts wear the throttle body, and cause air leaks and the throttle blades to be misaligned and bind in the worst cases. The float might get heavy with fuel seepage. Crap and debris might be blocking passages. Some of the other carbs from GM will have identical castings, but have different stamped numbers due to different throttle body sizes and different jetting. Another modification that I am going to do, is to knock out the "APT plug", and put in a pipe plug, so that I have access to the "Adjustable Part Throttle" screw. This limits the travel of the metering rods in the carburetor, and can help eliminate flat spots in the part throttle condition. "They say" to an O2 sensor in a bung welded to the exhaust to get the perfect tuning done. Another reason to open the carburetor up, is to replace the plunger for the accelerator pump. Apparently the fuel now has more alcohol in it, and attacks the rubber of the stock accelerator pump from the 1980s. An article with pictures: http://www.hotrod.com/articles...0607-quadrajet-tech/ Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.