Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

6/12 6/12Formally known as "Humbojb"  |

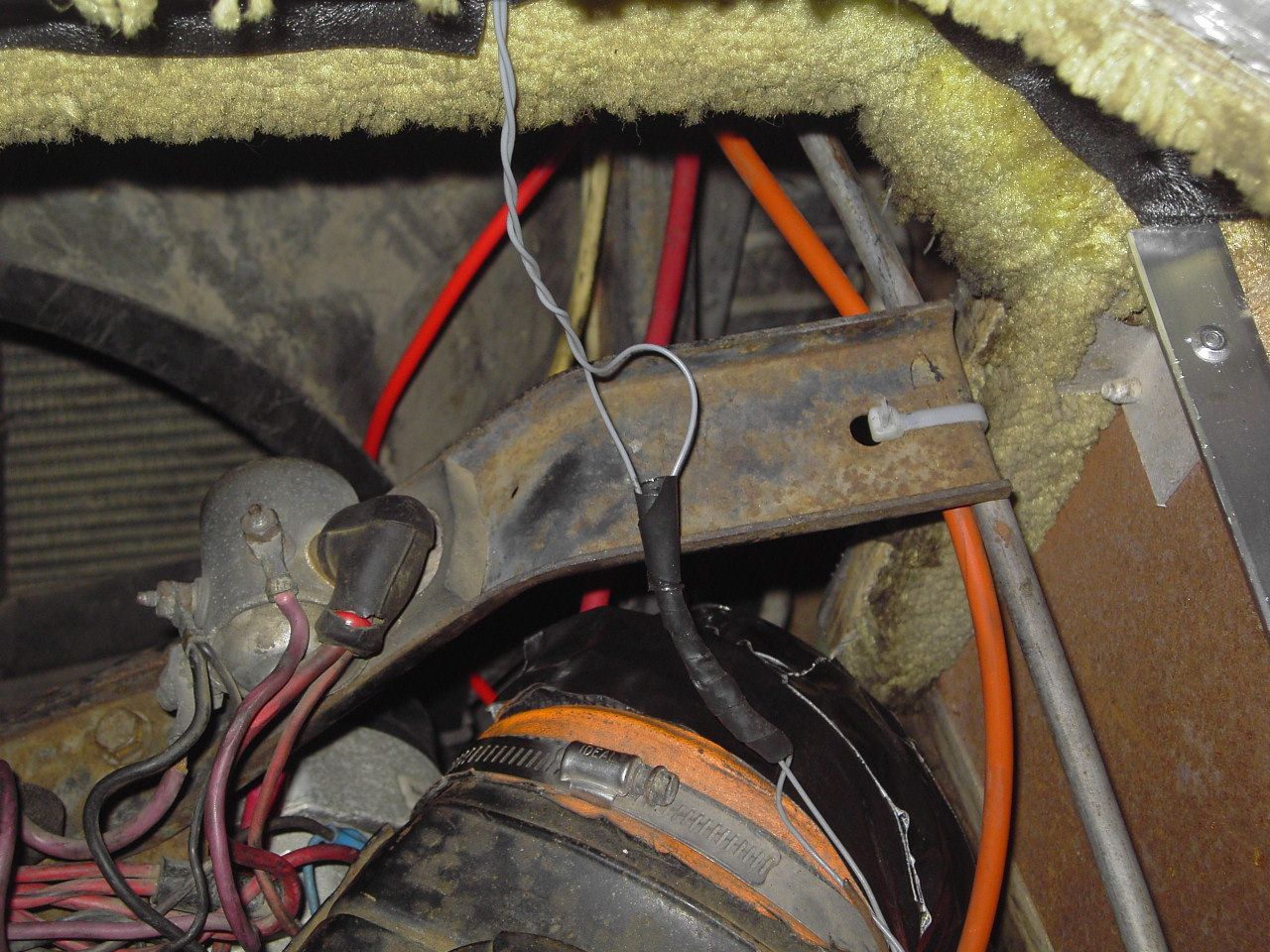

In the process of installing a new starter, we got into a discussion with the Sure Power Products people about isolators. Our house batteries are connected to the #2 terminal. Our vehicle battery is connected to #1 terminal via a circuitous route. The big red wire goes from the engine battery to the starter selenoid, thence to a round thing on top of the engine that has many red, pink and black wires going to and from it. One of the red wires goes to the #1 terminal on the isolator. The large red alternator wire is connected to the 'A' terminal of the isolator. Question is what is the round thing in the front of the engine? It's mounted on a bracket near and above the alternator. Pictures attached

| |||||||||||

|

"Host" of Barthmobile.com 1/19 1/19 |

That looks like a constant duty solenoid or a starter solenoid.

| |||||||||||||||

| ||||||||||||||||

| First Month Member |

It's a big relay, sometimes (incorrectly) called a solenoid. On airliners, it would be called a contacter, and at GM, it is a magnetic switch. It is used to carry power to the starter when you crank. Later tonight, I will send you three scans from the manual on the hot start problem this is supposed to cure. . 84 30T PeeThirty-Something, 502 powered | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

In that application, to be even more precise it is a: non grounding, 4 terminal, intermittent duty, electromagnetic relay. http://www.napaonline.com/Sear...MPEST80SB_0213350342 But, if you go to NAPA to get that part tell em you want a Non Grounding, 4 Terminal, Starter Solenoid Switch

| |||||||||||||||

| ||||||||||||||||

6/12 6/12Formally known as "Humbojb"  |

So I gather I should not take it off Jim

| ||||||||||||

|

| The Old Man and No Barth |

Considering the responses from the two Bills, East coast, & West coast, neither of whom I would ever contradict (at least publicly), I believe you have reached a sound conclusion. | |||

|

| First Month Member |

You could, and things would probably be fine. However, in a marginal situation, the starter solenoid might find itself getting insufficient current through the start switch and its wiring. A heat-soaked Chevy starter needs all the help it can get. This mod is popular on ski boats, too, mainly because of the length of wiring involved from the start switch up front and back to the starter. If it goes out, you probably have another one just like it that can be used as a spare. The aux start relay, which parallels coach and chassis batteries for starting the engine if the chassis batteries are weak and the coach batteries are strong. Or, better yet, if the genset is charging them. You can actually drive home this way with a bad alternator. . 84 30T PeeThirty-Something, 502 powered | |||

|

| First Month Member |

Well, ya know, Winnebago does use a constant-duty version that looks just like that as an isolator. So did Newport. I recommend such a set up to anyone who does not like the .7 volt drop inherent in a diode isolator and doesn't want to go Schottky. . 84 30T PeeThirty-Something, 502 powered | |||

|

6/12 6/12Formally known as "Humbojb"  |

The factory Technical Service Bulletin that Bill H sent me says that this was installed to solve hot start problems when heat expansion of the "S" terminal on the starter motor caused an internal open circuit in the starter.(Can't believe I said all that cause I really don't know what it means totally, maybe sort of). Bear with me. How do you know which terminal is the "S" terminal? So, we have a brand new Delco ministarter that supposedly doesn't care if it gets hot because it works on some 'permanent magnet' principle. We also will wrap the new starter, including the selenoid, with Thermo Tec starter wrap, and we will put a Moroso heat shield on the starter as additional protection from the manifold heat. And we will install a Termotec blanket over the manifold underneath the area where the starter is. Bill N.Y. has helped with some rewiring, but my question is: If I've gone to all this trouble to keep the starter from getting hot and it's not supposed to care if it gets hot anyway, why don't I remove the entire non grounding, 4 terminal, intermittent duty, electromagnetic relay? I just want to clean up the engine compartment of wires that will eventually need to be replaced again due to heat etc. BTW, I know that Thorley voids the warranty if the headers are wrapped. The Thermotec blanket is sort of like a flexible heat shield. I called Thorley and the said they didn't have heat shields for their headers. Jim

| ||||||||||||

|

| First Month Member |

BTW, the stud that expanded was on the solenoid, not the starter, as they wrote. Starters often come with solenoids, and it is common to refer to them as one unit. On the original starter in place when the thing was written, the Delco solenoid on top of the starter had an S molded into the bakelite. Additionally, the S terminal was a 10-32 stud, while the other one (a relic from days gone by when Kettering ignitions had dropping resistors) was an 8-32 stud. Now, on your GM mini starter, there is only one small terminal. That is the S terminal. I really don't know if it has had a problem growing with heat, or not.

The motor has permanent magnet field windings instead of electromagnetic. Anyone who says they don't mind heat didn't pay attention in high school physics. The virtue of a mini starter (aside from its gear reduction) is its small size. This compactness gets it (and it's solenoid) a little farther away from the starter.

This is a good thing.

This is not a good thing. Steel tube headers do not last as long if wrapped or insulated. I would recommend installing the blanket so that it is between the starter and the headers, but allows air flow around the headers.

The main issue has always been the sensitivity of the solenoid to heat. There is a particular issue of a long screw getting hot and expanding, causing loose contact. This was partially addressed by a bulletin that called for a special nut with a Belleville washer built into it. This maintained constant tightness of the connection to the S wire regardless of heat-induced expansion. Is your starter S terminal a 10-32? If so, I will hunt down the GM part number. Additionally, GM also came out with a high heat solenoid. It is worth noting that they never made a high heat starter, just the solenoid. BTW, I will send the GM info on this to anyone with an E mail address.

That is a good question. As I mentioned before, the old starter would work OK most of the time without the relay. The relay was a later fix to be sure that there was ample current carrying ability to get as much power as possible to the solenoid. Once the solenoid did a nice hard click, all was well, regardless of the new relay or not. The relay also takes some load off the ignition switch and the neutral start switch, as well. Now............I have not measured the current draw of the mini starter vis a vis the old starter. I have three vehicles with mini starters and only the boat has the old starter, but it is a Mercury reverse rotation starter, so I don't know if measuring it will tell me anything. Perhaps next week, when my Barth gets back home, I will drag out the spare starter and measure the solenoid currents. So........after that preamble, the short answer is, "It depends." Have you heard that before? It depends on: 1. How much less current does the mini starter solenoid draw? 2. How lucky do ya feel today?

The worst spot is down by the starter, and you are already addressing that.

Someone there has a short memory. Or low seniority. There was a regime change there after Doug and Mrs Thorley split the sheets. He got his car and the dog and she got the header business. Employees come and go, now. Anyway, we can go several ways on this: 1. I can fax you a drawing of the heat shield Thorley provided me. 2. I can send the drawing by US Snail. 3. I can scan and Email a drawing. 4. Next week, when Barth is home again, I can take a photo of it installed and send or post it. 5. I saved the best for last. You can make a super duper custom fit heat shield that is way better than Thorley's universal fit-anywhere heat shield. Cut a cardboard pattern to block any heat from the header from reaching the starter. It will end up a weird shape. Make one out of steel or aluminum. Hold it up in position, and mark two cuts coming in about 2 inches from the edge that are parallel and 3/4" apart. The cuts will line up with a fairly straight section of header tube. After the cuts are made, bend the tab 90 degrees. Then bend the tab back about 1/2-3/4 inch from the first bend. This tab will be mounted to the header tube with a worm drive clamp. Do this in two or three places. On the heat shield. This will protect the starter. If you can find it, a layer of asbestos furnace lagging will help. High temp silicone rubber will hold it in place. While you are doing this, take a look at how close the oil filter is to the header on the other side. The whole heat shield thing sounds way worse than it is. It is just a piece of sheet metal with tabs cut to make legs to raise it away from the headers. BTW, none of this is Barth-specific, so don't have any "Holy Cow, what did I get into?" thoughts. NOW.............the worse problem on motor home engine heat damage is done during idle after a hot run or after shut down. I have posted on this before, with a couple of cures. 1. Easy idle after a hot drive, rather than a hot shutdown. This lets doghouse temps get cooler somewhat. 2. Thermostatically-controlled electric fan that detects doghouse temp rise after shutdown and runs until it detects cooler temps. It also will kick in while in slow traffic or stop and go. A side benefit of the electric fan is that it will help out if the factory fan clutch fails. They all do. I was able to complete a trip with no drama, thanks to that. . 84 30T PeeThirty-Something, 502 powered | |||

|

8/10 8/10 |

Have had a phantom electrical issue since last November. Started on my last trip out, just prior to winter storage. Decided to wait for spring to figure-it-out. Took a while to determine [since I have no idea what I am doing], but took Rusty's advice from an earlier post and gave the Constant Duty Solenoid/Relay [located in the forward electrical compartment] a little tap with a "little" tac-hammer ...the problem stopped immediately. I removed the solenoid and gave it a "shake" and it almost sounded as-if and felt as-if there were fluid inside(???) Decided to replace: NAPA ST80 $51.00 NAPA ST85 $58.00 -OR- You can consider a BWD S603 Advanced Auto Parts $29.00 O'Reilly Auto Parts $33.00 There's an O'Reilly right across the street from NAPA here in town, so I went with the BWD S306. Everything is now working GREAT!!! ...try a "hammer" next time??? ~Mac~ 1990 31 Foot Regency Spartan Chassis Cummins 6CTA8.3 Alison MT643, 4-speed 8905-0123-31RDS-A2 | |||

|

Maybe I misunderstood what Bill said here, but isn't this solenoid actually the aux start relay? If it only serves to short the coach and vehicle batteries together, I don't see what else it could be. The important question is, "where does the 12V that activates the solenoid come from?" Hopefully you can determine whether it goes to the "save your vacation because you accidentally left the headlights on" button.

| ||||

|

| First Month Member |

The relay pictured (more or less above the alternator) is a GM fitment. It serves to assure adequate current to the starter solenoid by use of heavier and shorter wire, without the resistance of the start function of the ignition switch. It also eases the load on the ignition switch, as it only carries enough current to close the points. The aux start relay looks alike. Mine is on the inside of the right frame rail, near the battery box. Others could be located elsewhere, depending on the location of the batteries. PM me with your e mail addy if you would like a copy of the GM manual pages on this, or a copy of my Barth factory wiring diagram. . 84 30T PeeThirty-Something, 502 powered | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Most problems arise when someone installs a intermittent duty solenoid in place of a constant duty solenoid. Yes, a little cheaper. Yes, they look the same. No, they do not perform the same functions. In my emergency road service business we only carry the "non grounding, 4 terminal, constant duty, electromagnetic relay" on our service trucks as this can be used to parallel batteries, operate liftgates, coach levelers, starter solenoids, etc... try to use the intermittent relay in a constant duty application and you're going to run into problems down the road. If you HAVE to use solenoids or relays... I would prefer to use a "latching relay" as a main supply with a momentary on/off switch for activation/deactivation as this uses NO CURRENT when latched or unlatched - I would use a "non grounding, 4 terminal, constant duty, electromagnetic relay" to parallel batteries with the ignition being the source. I would eliminate the diode battery isolator and only charge the coach batteries. If you need a starter solenoid I would use the "non grounding, 4 terminal, intermittent duty, electromagnetic relay" What the post was about initially was Jim and Tere trying to clean up their mess of wires and to simplify what they had. They replaced the starter with a high torque starter and they no longer needed the extra solenoid to help them start. This was eliminated in this post. My setup charges just the start battery and uses no solenoids/relays as all paralleling is done via a big switch. Bullet proof in operation, but you must make a conscious decision to turn a switch instead of relying on an automated feature.  Another issue with paralleling batteries to recharge your house batteries is the danger of burning up an alternator if your house batteries are depleted. This can be overcome in my setup by starting up the generator while driving and leaving my paralleling switch off. But, if you have a solenoid bridging all batteries via an ignition source, you do not have this option anymore. If you understand electricity flow on these coaches, you can overcome anything with a few handtools. If you don't, then you must rely on automation to overcome what you do not know and hope that the inherent risks associated with that do not play out while you are enjoying your coach.

| |||||||||||||||

| ||||||||||||||||

| First Month Member |

I agree with you on the simplicity of having just a paralleling switch or (even simpler) a jumper. That is how I operated for years (due to an on-the-road failure of the paralleling relay) up until I recently eliminated the chassis battery. However, before we went solar, I spent decades with parallel alternator charging, and never burnt up an alternator. However, these were mostly Delcotrons. One Autolite. I believe there were two factors that kept the alternators from overworking themselves: 1. The built-in temperature compensation that reduces output when fully warmed up. (I don't know if this applies to non-Delco alternators or not.) 2. The limiting factor of the alternator reading the best battery and not putting as much into the lower batteries as they can absorb. I did use a marine switch at one time to shift the alternator from one battery to another. Running the alternator directly to a low coach battery definitely made it work harder, as evidenced by engine loading, ammeter reading and belt squeal if not perfectly adjusted. Perhaps this arrangement did not fail because I only had one coach battery at that time. I know several boat owners who have used their engine alternator to charge their house batteries for years and years with good results. . 84 30T PeeThirty-Something, 502 powered | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.