Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

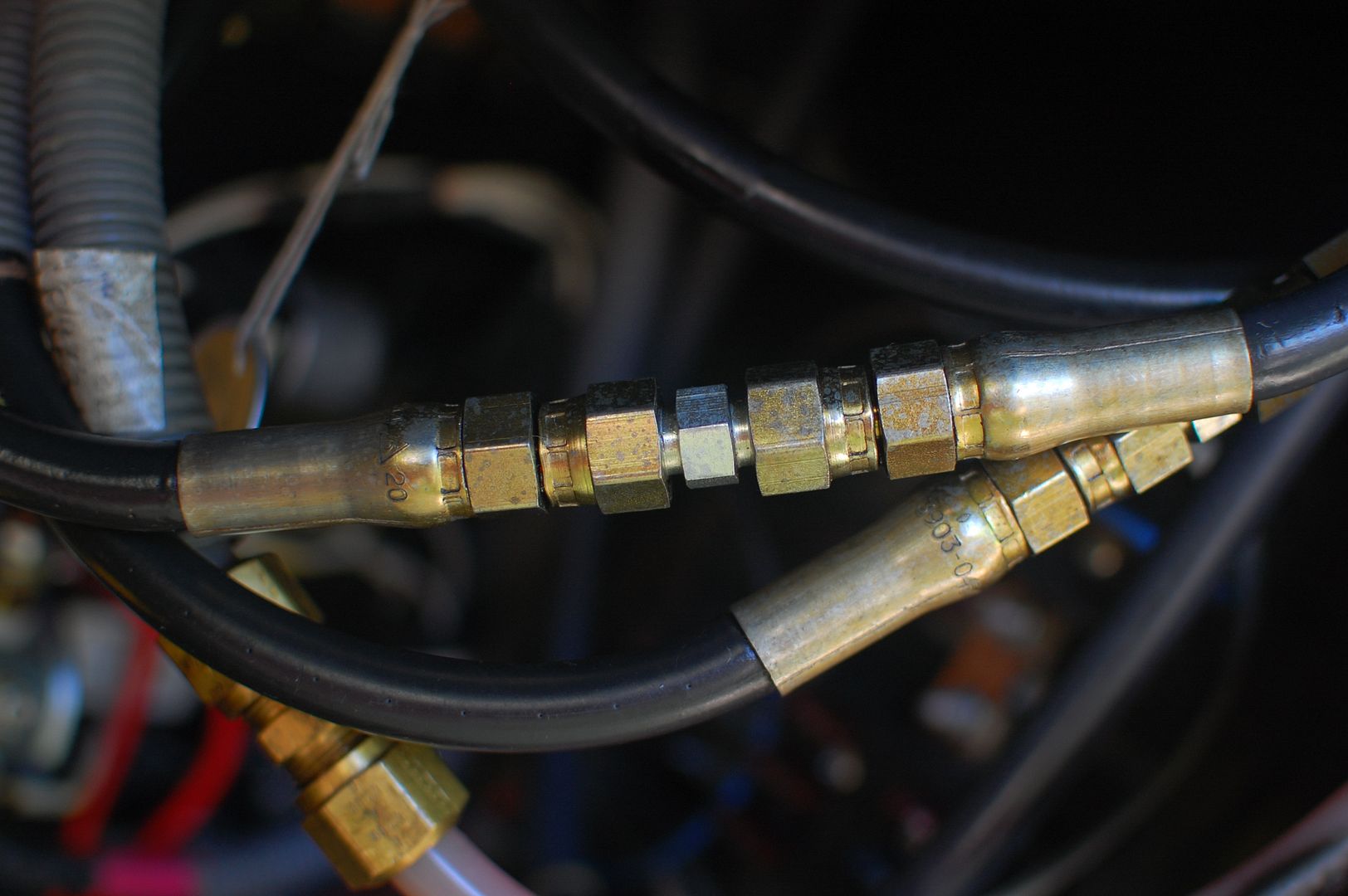

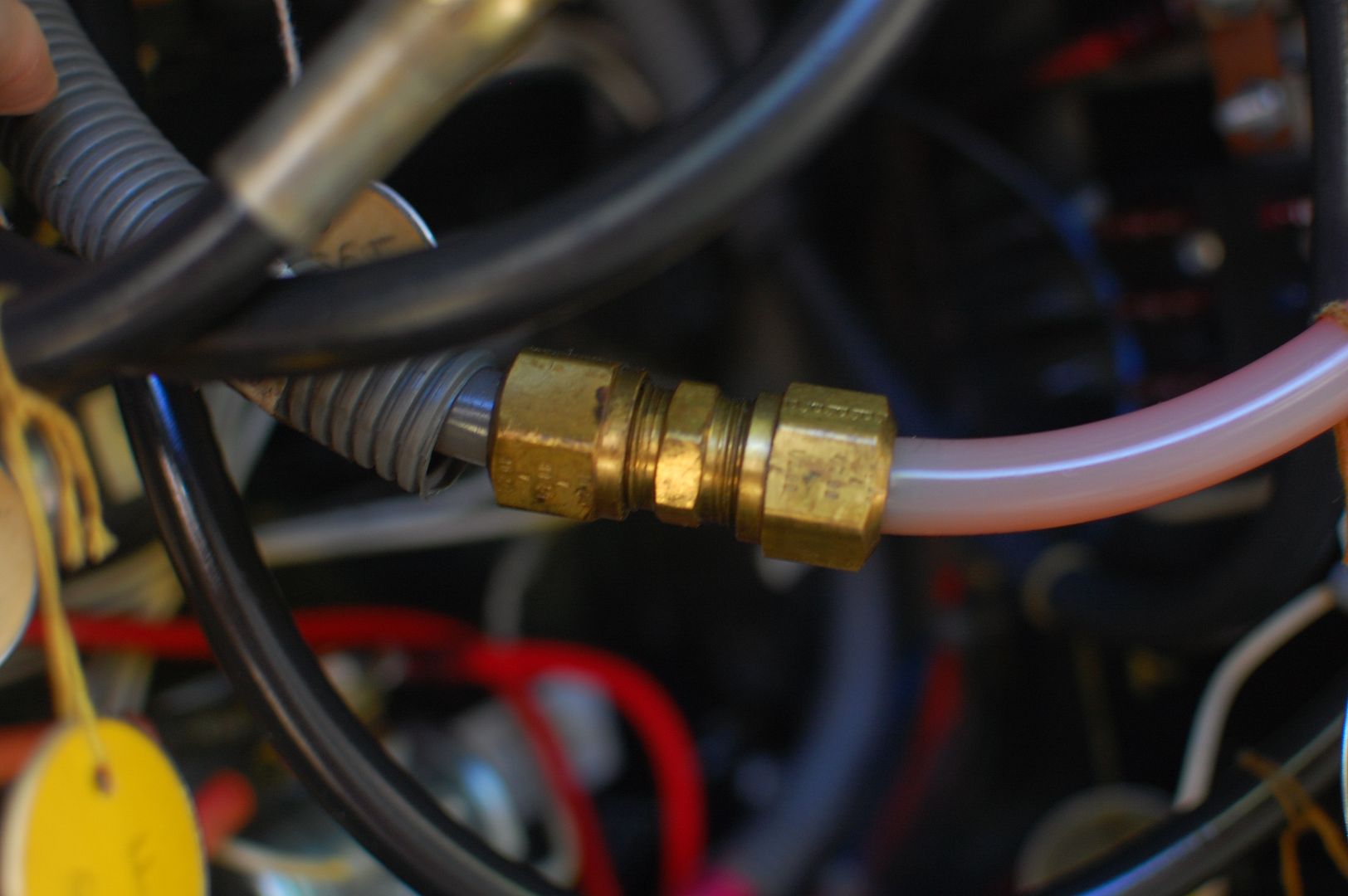

Hi everyone, We ran the leveling system this weekend and found a leak in the high pressure hydraulic line/s for the front leveling jacks. The leak/s appear minor at the line connectors and they might just need to be tightened. Are these lines depressurized once the jacks are fully retracted and is there a hold and tightening sequence or torque spec to the connectors? Also the pump return line is a different line type and connector and looks like it may have been replaced. Is this a low/lower pressure line? All advice is appreciated. Photo of high pressure line connectors.  Photo of return line and connector.  Thanks, Wally | |||

|

FKA: noble97monarch 3/12 3/12 |

That line always leaked. I'd get it tight, then it would leak again. Must be made by Harley Davidson. The return line is not under pressure. Not sure how the pressurized line operates, but it only ever had a few drops during cycling. I decided it did the electrical box good to be in a hydraulic rain forest and just had a rag on the floor to sop up the small amount of fluid.  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

Thanks Corey, It looks like it'd been doing it for a while but may be getting worse and needs to be tightened. I've never tightened hydraulic connectors before and don't want to make it worse. Clean up could get tedious. Is there a hold and tightening sequence to the connector? I kinda wondered why Barth thought routing the hydraulic lines and connectors into the electrical compartment was the best way to handle them. Thanks, Wally | ||||

|

FKA: noble97monarch 3/12 3/12 |

I would try teflon tape on the junctions. The only tightening sequence is to be sure to use two wrenches, one to hold the the center connector and the second to tighten the cap nut. Clean it well and spray with foot powder. In this way you can quickly see if and where it's leaking after the tightening.  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

I work on hydraulics when it comes to tractor trailer truck repair... Liftgates, car carriers and power steering are all hydraulics and when they break, or leak out, you usually have field repairs done on the hoses to "Get em home". Sadly, these types of repairs are usually permanent and many people just keep running them with a slight leak. This does not have to be. A little primer on the different types of fittings and field repair splices can go a long way in permanently fixing a little hydraulic leak. Not all fittings are made to be used as a coupler. SAE - JIC and Pipe Threads are not the same thing. SAE Fitting: This indicates a part has a 45 degree flare JIC Fitting: This indicates a part has a 37 degree flare JIC 37° - SAE 45° Dual Angle Seat Fitting are made so that can be screwed onto either a 37° or a 45° fitting. A crappy fitting, but one that might come in handy in a pinch. Read the fitting connector at the hose end and get a proper coupler fitting to replace the one that is leaking - a good thick copper coupler can handle a little imperfection in the mating surfaces so you might want to get the correct style. 37° and 45° fittings and tooling are not interchangeable due to the different flaring angles. Mixing them can cause leakage at the flare. Myself: I would not use Teflon in a mated seat area - pipe threads yes, but not a flared end.

| |||||||||||||||

| ||||||||||||||||

Thanks Corey, Bill, Turned out Tonka needed a little more than a turn of the screw. She had two leaking lines that needed to be ordered and manufactured by HWH and replaced. Definitely above my pay grade. That's why we have good people who earn their living helping those of us without the knowlege, skills, tools and time. Wally | ||||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.