Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

I have a 91 freightliner chassis, rear diesel, pusher frame, cummins 6bt. I have a squeak, it is not the compressor or compressor idler pulley, these devices are run off of the second groove of the fan pulley, I disconnected these and I still have the intermittent squeak, so much for an easy fix... A serpentine belt surrounds the crank pulley and extends up to the fan pulley and then to an idler, alternator, water pump and then back to the crank. I can lessen the squeak by spraying the belt with water, but it comes back. I am spraying the back side of the belt, but the only thing that runs off the back side of the belt is the water pump.... The pump spun easily this spring when I replaced the idler/tensioner. Is there something about the Cummins 6bt engine's water pump that could promote a squeak? it does sound like a belt squeak, but I am not entirely certain. Any suggestions or recommendation is appreciated. I plan on pulling the belt and spin some pulleys tomorrow, the belt is a PIA to pull off the bottom pulley due to very close tolerances, but I would rather be certain of what I have before heading to Chattanooga next week. Thanks  Doug Bywaters Near Skyline Drive Virginia!  | |||

|

Captain Doom |

I have no Instant Cure, but among the things I'd suspect is the idler arm bearing - not the pulley bearing, but the attachment point and spring for the idler arm itself. While I have a GM/AMG 6.5L TD, I discovered the idler arm mount deserved some lube. Then I discovered the pulley damper on the crankshaft needed replacing, the root cause of the idler arm's activity and the noise. But since I'm thoroughly unfamiliar with the 5.9L Cummins, don't listen to me... But just to rub in a bit of salt, I can replace the serpentine belt on mine in about 5 minutes. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

Yep, I also have a 83 6.5 and the belt is not too bad to replace as long as one has the belt routing committed to memory, or the schematic is handy... I replaced the tensioner this spring, but I will also test it. What makes my belt difficult is the clearance allowed around the crank pulley, if it is not placed correctly it damages the belt. I probably just need more practice... Thanks Rusty Doug Bywaters Near Skyline Drive Virginia!  | ||||

|

"Host" of Barthmobile.com 1/19 1/19 |

The original tensioner was metal - some of the newer ones are plastic. I've seen instances where the new tensioner makes a slight squeal if it's the plastic one. Also, I've seen belts loose there ability to grab the pulleys, thus causing a squeal because of slippage. I've seen some newer tensioners have a slightly different design. These pulleys do not allow full tension when the belt starts to wear down. Check the arrow on the tensioner housing to make sure it's within the proper belt range. Did you replace the belt with a HD version? Gates makes 2 types of serpentine belts, so make sure you get the heavy duty/severe duty version.

| |||||||||||||||

| ||||||||||||||||

Replacing the belt on the 6B is easy. It took 3 hours the first time without the proper tools and 5 minutes the second. Just make sure you have a long handled 3/8" socket or breaker bar. Just a note on belts. When you change belts keep the old ones with you. This way if one breaks on the road you have a spare. '92 Barth Breakaway - 30' 5.9 Cummins (6B) 300+ HP 2000 Allison Front entrance | ||||

|

Captain Doom |

This is way out, but I remembered an issue with a squeak I thought was the belts - it was a loose exhaust flange, and it moved enough to squeak. It was easy enough to detect when I got near it. BTW, a mechanic's stethoscope can come in handy. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

I spent some quality time back there tonight ( I honestly know the bottom better than the top side) and removed the belt. It must be the belt, I will pick one up tomorrow. I spun the fan and water pump, both of them are free. The idler and and alternator are new, and are tight without squeak. I'll update when I put then new belt on. I don't think there is any real concern on the ride down 81 next week,,,but there is always something thanks for all the advise Doug Bywaters Near Skyline Drive Virginia!  | ||||

|

1/09 1/09 |

well i might be a litle late with this but a digital camera helps with assembly! | |||

|

You know, I took that camera out there with me tonight and the thing did not volunteer to pick up a wrench or hold the drop light.... I did take photos, but getting good angle on a pusher is difficult. I bought the "cummins" belt today, it set me back $57.00, and put it on tonight and there was no Squeak! I found that the one I removed was slick and shiny on the back side, even though the belt was purchased new in April. I thought about causes of the worn belt and the only thing that touches it is either the tensioner or water pump. When I bought this "jewel" I found a considerable amount of rust on about everything, even the pulleys. The tensioner was also locked up, which meant the belt did not ride tightly on the pulleys. The evidence was the amount of rust on the water pump pulley (which I did not clean off this spring) Well, since I had it apart I spent some quality time with sand paper disk on a 4" grinder and made is as smooth as a counter top. After I assembled it everything is quiet as diesel can be. So, the short answer is belts can squeak just like a dry bearing, which is what I thought I had. I have the old one near the engine, and hope I will never need it.... Doug Bywaters Near Skyline Drive Virginia!  | ||||

|

| The Old Man and No Barth |

Rusty pulleys can chew up belts in no time. Been there, done that | |||

|

You probably were experiencing quite a bit of belt slippage due to the tensioner not being able to fully apply enough pressure to prevent it. I had a similar problem when I changed to a 200 amp alternator, the tensioner was not clock enough to put a full tension on the belt, every time the "Big boy" relay came on line to engage the house batteries to the charging line I got a really bad squeak, more like a scream! I also have had troubles with squeaks if I clean the engine bay with Simple green, get that on the belt, it make a lot of noise for a long time. Good to hear that you have solved your troubles! Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

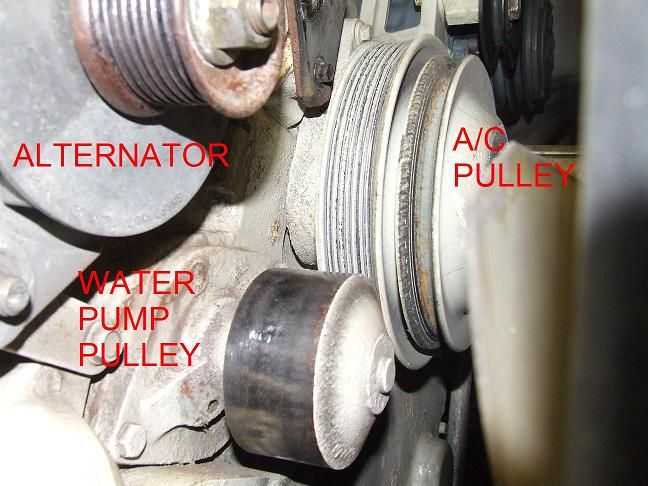

Yep, the belt was not tight when I bought it home this spring due to a locked up tensioner, I did replace the tensioner and pulley without cleaning rust off the smooth water pump pulley. I did not know how badly the rusty pulley would wear out a belts "back side". I hope this thread helps out someone. I know I have gleaned a lot of great information off these pages, and so far this is the best forum I have read, regardless of make or model. By the way, the tensioner and pulley is not shown below, I had removed it to polish up the water pump pulley. The tensioner is normally located between the groved pulleys of the alternator and fan drive pulley.  Doug Bywaters Near Skyline Drive Virginia!  | ||||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.