Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

|

I consolidated my notes to myself, and made a list of parts that might prove useful to others. 1987 P30 chassis key numbers, with the W engine. 454 engine, Quadrajet carburetor, HEI ignition distribuor, two air pumps, 1 serpentine belt, 2 v belts This chassis began production as a late-1986 production change, and continued through 1989. 1989 is the last year for the carburetor I think on the 454. The belts routing may have continued until 1991. Some parts extend in date beyond the beginning and the end of this exact specific configuration. There are options which might make other P30 chassis rigs from the year have different configuration items. Examples: 120 amp alternator instead of 100 amp, 19.5 rims or smaller rims. I generally listed the Delco part number thinking that other brands would cross reference this. Other brands might also cost half as much at retail. Delco sometimes has a variety of quality, such as distributor caps, with various metals and plastics used. My intent is to print this out and pack it in the rig. Also, I hope easy access to these numbers will help other folks with P30 rigs from the era. As I get more information, and learn of mistakes, I will make correction in this note. I will bring my VIN to a GM parts guy and see if he can tell me all the option codes present. carburetor Quadrajet 17085212 This is an 800 CFM spread-bore Quadrajet, with Venturi boosters in the primary bores. Delco 24-3545 (P30 1985-1989) Holley rebuilt 64-70113 NAPA wants $200 more than Autozone on the day I checked pricing fuel pump ACDELCO Part # 42440 {MECHANICAL #06472478, 6472478} (P30 1985-1988) spark plugs ACDELCO Part # R44T {Standard Plug #05613867, 19157988, 5613867} (Chevrolet 1970-1989) SPARK PLUG .045 GAP ignition wires ACDELCO Part # 618T {#12072181} (P30 1985-1988) BE ADVISED THAT HEADERS COMPLICATES MATTERS. WIRE KIT,SPLG w/FEDERAL EMIS(NA5) HEI module ACDELCO Part # D1906 {#10482820, 19180771} (Chevrolet 1974-1989) MODULE,ELEK IGN CONT oil filter ACDELCO Part # PF1218 (1966-2002) FRAM Part # PH5 air filter ACDELCO Part # A753C (1980-1991) distributor cap ACDELCO Part # D336X {#01974408, 19110931, 1974408, AD336, D336} CHEVROLET (1974 - 1990) CAP,DISTR; CARBURETED ENGINE ignition rotor ACDELCO Part # D448X {replaces D448CS; replaces D448 #10498150, 12366641, 19110934, AD448, D448, D448CS} CHEVROLET (1974 - 1991) ROTOR,DISTR; FUEL INJECTED ENGINE {i'd say this is for carburetors also} ignition coil ACDELCO Part # D573A {replaces D566A #89056789, D566A} (Chevrolet 1974-1989) alternator ACDELCO Part # 3342337 {105 AMP #19135895} (P30 1987-1993) GENERATOR,(REMAN) DELCO CS130; 105 AMPS starter ACDELCO Part # 3361823 {#10496873, 19136132, 323367, 88863064} (P30 1980 - 1994) (REMAN) DELCO 10MT; 1.5 KW solenoid STANDARD MOTOR PRODUCTS Part # SS251 (Chevrolet 1982-1995) round thing on top of the engine TBD fan clutch AACDELCO Part # 154949 {#154415, 154416, 154593, 154606, 15625457, 15625458, 15963247, 22136844, 88961767} (Chevrolet 1970 - 1997) CLUTCH,FAN BLADE CODE DU CLUTCH,FAN BLADE CODE GY CLUTCH,FAN BLADE CODE FD,RL,HW water pump ACDELCO Part # 252608 {Big Block Engine ONLY #88926122} (Chevrolet 1973-1997) PUMP KIT,WAT STANDARD ROTATION thermostat ACDELCO Part # 13187 {195 DEG #12514334} (Chevrolet 1966-1992) THERMOSTAT,ENG COOL lower radiator hose ACDELCO Part # 24162L {1 1/2" x 1 3/4" x 25 3/16" #88908451} HOSE,MOLDED CHASSIS MTD., MOTOR HOME; LWR (P30 motorhome 1982-1999) upper radiator hose ACDELCO Part # 26126X {1 1/4" x 1 1/2" x 35 11/16" #88908824} (P30 motorhome 1985 - 1989) HOSE,MOLDED CHASSIS MTD., MOTOR HOME; UPR radiator VISTA-PRO Part # 431338 {#1544} (P30 motorhome 1987-1997) Fits w/o AC; w/HD Cooling; W/AC; w/ MAX Cooling radiator cap STANT Part # 10231 {Vented Cap (Open or Closed System) - 16 psi (SAE Range 14-18 psi) #11231} (1971-2006) On the belts, please be aware that you have option 7N4 on your RV, this means you have a different AC compressor than other P30 vans. serpentine belt ACDELCO Part # 6K560 {K06 13/16" x 56 5/8" #88932701} (P30 1985-1989) BELT,SERPENTINE FAN, ALT & A/P hydroboost pump belt ACDELCO Part # 15612 {HC41 13/32" x 61 5/8" #88934370} (1966 - 1991) BELT,V FAN, A/C & P/S other belt ACDELCO Part # 15450 {HC41 13/32" x 45 5/8" #88934334} (1966 - 1997) BELT,V FAN & P/S; w/o A/C BELT,V P/S TO A/P master cylinder TBD hydroboost pump TBD front wheel cylinder TBD rear wheel cylinder TBD front brake pads TBD rear brake pads TBD front shocks ACDELCO Part # 530203 {PREMIUM GAS CHARGED #88945371} (P30 1974-1999) ABSORBER,FRT SHK INDEPENDENT FRT SUSP rear shocks ACDELCO Part # 530151 {PREMIUM GAS CHARGED #88945319} (P30 1973-1999) ABSORBER,RR SHK I-BEAM FRT SUSP ABSORBER,RR SHK INDEPENDENT FRT SUSP AC Compressor ACDELCO Part # 1521619 {replaces 19144901 #19144901, 19192306} (P30 1986-1991) COMPRESSOR,A/C(REMAN) SD510HD CMPR, SANDEN MODEL U9125 Fuel filler hose Dayco 80304 2 needed motor mount ANCHOR Part # 2395 (1975-1997) thanks to www.rockauto.com for much of the source data. Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | ||

|

|

Here's a good note from Bill H on the chassis: http://barthmobile.com/eve/for...=731108582#731108582 Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

|

One thing that concerns me about the "belts" situation is that the Hydroboost pump gets one belt from the crankshaft pulley. GM trucks of the era get two belts between the two pulleys, so that there is not a single point of failure that would cause the truck to lose brake power. Last summer, my AC compressor bracket broke. Fortunately, because the belts were incorrectly routed, I did not lose brake power. I can't yet tell if the belt routing used did in fact cause the bracket to break, however, it had been welded earlier to repair it. Perhaps the alignment was off. I'd really like to have redundant drive belts to the hydroboost pump pulley. Is there a way of doing this economically? Matt GMC AC Mounts 1986 Option 7N4.PDF - (56 KB) ~ 7N4 Belts Routing 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

| First Month Member |

My 84 has two belts driving the PS/Hydroboost pump: Middle belt, Gates 15590(7590), wraps crank, pwr strg, AFT groove of AC comp & WP . Rear belt, Gates 15415(7415 or 7417?), wraps crank and power steering. I change them every two or three years. Cheap insurance. My air conditioner condenser is removed, so the compressor is just an idler pulley. I keep it in position just so my PS/Hydroboost has two belts to drive it. . 84 30T PeeThirty-Something, 502 powered | |||

|

|

I checked on using the rear-most empty groove in the crank and hydroboost pump pulleys. A 41" belt fits, but with no clearance to the water pump pulley. There would be rubbing occuring if this were to set up and run. The crankshaft pulley and water pump pulley are only about 3/8" apart at the closest. It would not be possible to substitute a different pulley on the water pump with another groove to the rear, because there is no clearance for this at the top of the water pump. I'll note this: it appears that one mode of "wearing out" for these belts is to narrow down and seat further in to the V grooves of the pulleys. So if your belt is no longer 13/32 of an inch wide, you know you have been warned. I got easier access to this area by removing the frame cross member just under the front of the engine. The brake system proportioning valve bolts on this. To adjust the hydroboost pump, you'll need to use a 15mm combination wrenchand a 13mm combination wrench. The big bolt on the pump is then reached with two 3/4 wrenches linked together. I did this stuff while replacing the fan clutch. I did that with the fan shroud in place. I removed the fan from the clutch, and then removed the clutch from the water pump. I didn't take the fan out of the shroud. So, no worries about installing it backwards. I reached some of the bolts from above, some from below. Long arms help. I used new bolts, studs, and nuts when reassembling the parts, so it would be easier. I didn't have a clear view of the area, so having parts that were dimensionally accurate eased the process. Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

| First Month Member |

In addition to wear, some belts are a little wider than others, even when new. It is not uncommon for GM alternators to have belt slippage when a narrow belt bottoms out and the sides no longer grip as well. Sometimes this shows up only on heavy electrical loads. Some manufacturers' pages will give width specs. Off-brand or house brand belts can be too narrow, too. NAPA sells two grades of belts. Warning: Thread drift follows.......Susan had a mechanic install a belt. A week later, it squealed. Investigation showed that he installed teh cheapie Mexican belt from NAPA, but filled out the invoice with the good belt with the good price. I went back and they told me to go fly a kite, so I raised a lot of hell, got the charge taken off the credit card, and got them in trouble with the Bureau of Automotive Repair and the AAA lifted their recommendation for them. The last time I drove by, they no longer advertised being able to do smog checks. I don't know if there is a connection or not, but shifty mechanics (if caught) don't last long in CA. Back on thread, I have always been happy with the top line of NAPA belts. But, they get replaced often, anyway, especially the hydroboost belt. . 84 30T PeeThirty-Something, 502 powered | |||

|

|

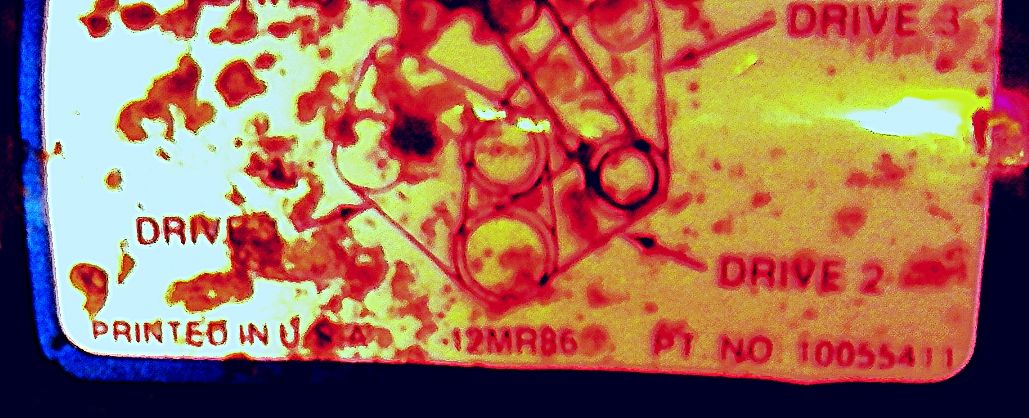

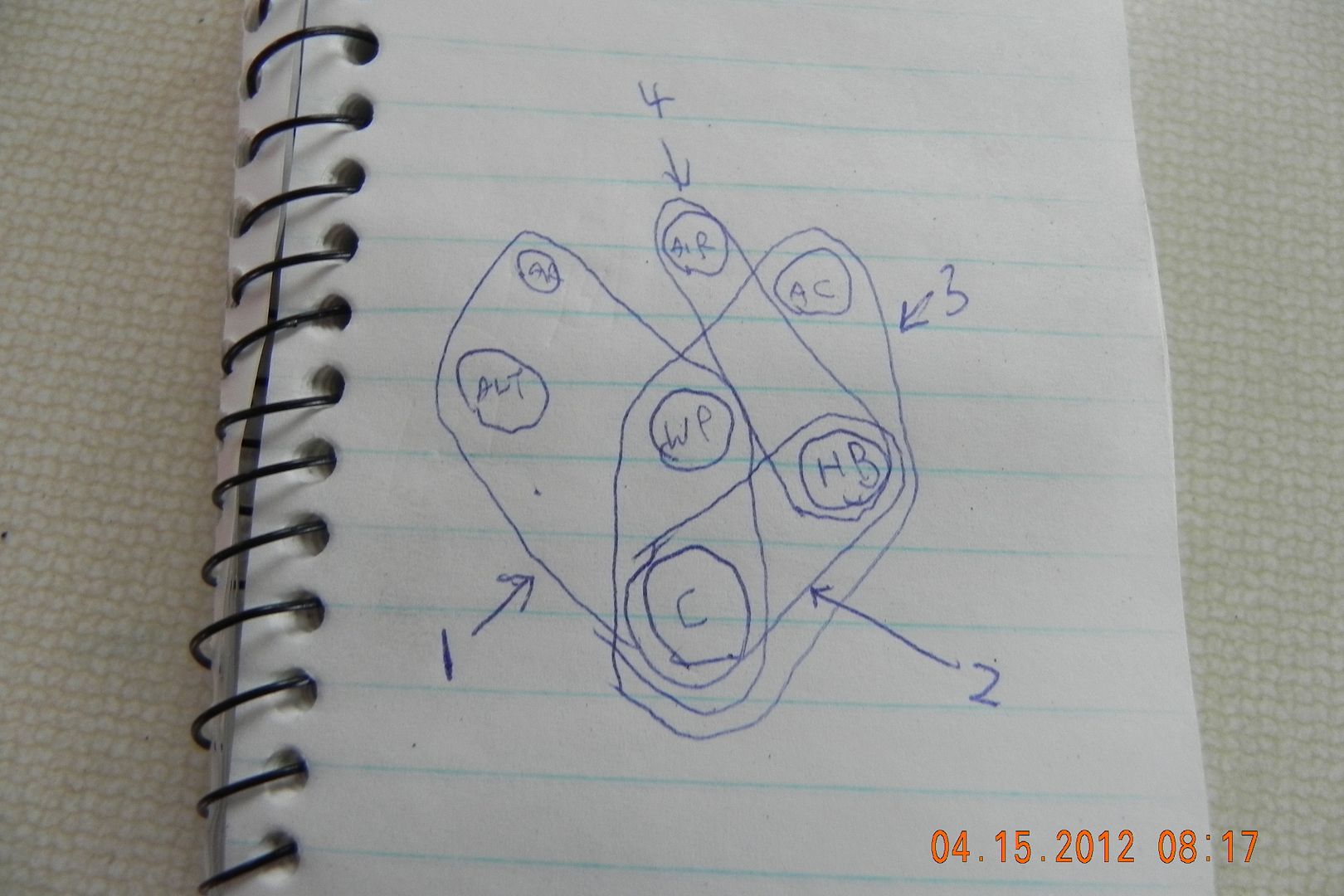

If you look at the 7N4 document above, it shows 3 belts. If you look at what Bill NY entered at http://barthmobile.com/eve/for...=344103292#344103292 you can see 3 belts. With the AC compressor removed, and some cleaning, I was able to get to see the sticker on the AIR pump bracket. Now, the sticker is hard to see, rust stains are coming through the back, but it shows 4 belts. Maybe I should try a different size belt for the crank to PS pump, and then I'll have two there.  So, did GM document this wrong in the manuals? Or did the engine designers do something wrong that was 'corrected' in documentation? In my case, I can't get the belt in place until I get the AC bracket in place, and that can't happen until I get the broken bolt out of the cylinder head. I'll try to get a better picture, I took a dozen today, and this was the best one. The camera was not happy that close. Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Try turning off the flash and let the camera draw out the light. Work well for me when a close shot seems tougher than it should be.

| |||||||||||||||

| ||||||||||||||||

|

I think P30 owners will want to know that the "Chevrolet Motor Home Chassis Service Guide" from perhaps 1992 can be downloaded. http://bdub.net/manuals/P30/P30.pdf happy motoring! Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

Official Barth Junkie |

I just posted much of the 86 Chev P30 service manual on the Ads, Documentation, etc forum. You will find belt diagrams and much more! 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Official Barth Junkie |

When I removed the AC compressor and bracket, I was able to put two identical belts 7410 on the power steering. Close fit under the fan pulley but they fit OK. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

8/11 8/11 |

I had uploaded the entire manual last year. It's in there! Billy & Helen Thibodeaux Retired from Billy Thibodeaux's Premiere RV, Inc. Scott, LA 70583 I-10 Exit 97 The Farm is near Duson, LA I-10 Exit 92 then N 1 mile on right Three Full 50 Amp RV Hookups ! billynhelen@me.com Data Tag: 9404-3908-36XI-2C 1994 Sovereign 36' Widebody on Spartan IC (Mountain Master Lite) Chassis. Powered by Cummins ISL9-450 Onan 8,000 Quiet Diesel Genset Toad: 2018 Chevy Colorado ZR2 Diesel with M&G Car Brake  | |||

|

|

There is a problem with the documentation from GM for the late '80s and early '90s P30/P32 Motorhome chassis machines. I'd looked up lots of websites for info on the belts routing, and usually see things like "My RV eats belts" and "I get them replaced every year". For instance, this shows 3 belts: http://truckroadservice.com/ba..._1986_option_7N4.pdf Here, http://bdub.net/manuals/P30/P30.pdf, in Appendix A, there is also a picture showing 3 belts, on page A-2. But, in that document, on page A-4, the documents lists 4 belts being used. I think the problem with the documentation is that GM subcontracted the bracket design to ARA and the documentation to another vendor. If you have a rig of this era, you will want to have new bolts ready to use on the cross member underneath the belts. There are also 2 bolts used to hold the brake system proportioning valve. This will ease the maintanence and inspection process. Here is what I saw when I took the cross member off.  The belts are swapping grooves and there are 4 belts in place. I am guessing that the mechanic who last worked this was basing his ideas off the GM manual and what the prior mechanic did. Btu only one belt is driving the hydroboost pump, and this pump pully is then driving two other belts. They say, "If you want something done right do it yourself". You will also find that due to the changes in ownership in the parts industry, things are not as they should be. Note that I have 2 belts, both from AutoZone, with the same part number, 15410, and that one is 1.1mm wide and one is 1mm wide.   GM specifies 3/8th of an inch. I would like to get a real 3/8th wide belt and not the metric mismatch. Due to the tight clearances from belt to belt, we need the 1mm wide belt so the belt seats deeper in the groove. Groovy huh! Here is a picture of a 1mm belt next to a 1.1mm belt. Note the difference in the positioning of the belt. I bet I am going to have to adjust/replace the 1.1mm belt sooner.  On the bracket for the top AIR pump, this label appears, but barely legible. This shows the correct routing for the belts.  This shows my drawing of that.  What further confuses the issue is that both the label and the manuals refer to the belts by number, but the number of the belt is not the order of installation of the belt. The correct ordering of the belts is 2, 3, and then 1 and 4. The belts are listed in yet a different order in table A-4 of P30.pdf. What we need to be sure of is that the hydroboost pump has two belts going to it from the crankshaft pulley. It is a critical safety concern, this pump powers brakes and steering. I don't think you can live without that. These next 4 show how tight the clearances are on the belts, from side to side and from top to top.     For getting the big fat bolt loose that is holding the hydroboost pump tight, I used two 3/4 wrenches linked together. It is a roughly 16 inches to the bolt from where you can get your hands. Maybe a "pro" can advise if there is a better way to get a torque on a bolt that can not be reached by hand. I am going to make sure I have 3/8" wide belts, as my next step. The brakes and steering both feel more powerful and secure as I drive now. I don't think I am imagining this. On purpose, I am not listing the part numbers here. If you have similar rig, you will indeed want the GM numbers from page A-4, but you will also want the dimensions of the belt. Some parts suppliers are not diligent about ensuring that the width of the belt they provide is what you require for the safety of your family. Be safe and have fun! Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

Official Barth Junkie |

I had the same problem, the AC belt never seemed to line up with anything. Since the AC and both air pumps were not hooked to anything they are gone. Since the 454 came with and without the right side air pump, the factory belt (w/o air pump) specified will work. My 86 has a flat ribbed belt for alternator, water pump and crank pulley: K5256 (20mm x 1355mm, same as OEM w/o air pump!) I installed 2 matched 7410 power steering belts (3/8 x 41 same as OEM!) A tight fit to install between the pulleys but will fit... seems to work fine. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

A couple of replies earlier, a few years ago, I had some postings of how car parts vendors have substituted for the 3/8" belts we need. Some will give you 10mm, some will give 11mm. Probably they got a good deal on buying 25 million in Asia, and changed their catalogs to match what they have. It is good for them, but not good for our finicky belts and pulleys, especially on the late 1980s P30 platform. Apparently with auto makers going metric, the V belts for automotive purposes aren't made any more on an inch basis. I found that Gates actually makes the correctly sized belts, in their industrial line. The "Super HC" line has 3/8 width belts, rated for continuous operation at 250F and are oil resistant. I am installing the 3VX400 from the crank to the PS pump, it is 3/8x40". I am installing the 3VX600 from the crank to the water pump to the AC to the PS pump, it is 3/8x60". Happy Roads Ahead! Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.