Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

1/11 1/11 |

Hello on the way home from the smokeys mtns. we developed a air leak in the rear tanks.I did not use the breaks the air kept going down from 110 to 90 lbs. then back up to 110 the hole cycle took approx 3mim.45 seconds each time .Did look under the coach on the way home at a rest stop.I sprayed soap on the bags did not find a leak( YET) .When we stop for the night the air does not go down.I did find some rubber loose on the right air bag ,cut it off, sitll did not find any leak .this was the same side I hit the tire on75 a few weeks back. any thoughts? lenny lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | ||

|

"Host" of Barthmobile.com 1/19 1/19 |

Sounds like you have a blown brake chamber Lenny. Push the release button in on the dash with the engine off and see if you hear an airleak. Make sure you have full air when you do this. Now, if the issue is only recovery time while the brakes are in the parked position... Then it could be a blown air compressor discharge hose, a bad air dryer, a defective D-2 Air governor or a weak air compressor. You need to determine if the problem is only evident while driving or while parked. Your compressor cycles with a 20lbs differential. If your full air psi is 110lbs - then the system can bleed down to 90lbs before it will kick back in to build back up. If you are curious, read this entire thread for a primer on how the air compressor works.

| |||||||||||||||

| ||||||||||||||||

1/11 1/11 |

my air stays up all night. When it is down only takes 3min to fill both tanks.the loss of air is only when driving. I can hear the air release when at idle and my tanks are at 110.when driving it takes 45 seconds or less to fill from 90 lbs. to 110. lenny lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

You don't need to drive down the road to do this test. Test 1) Start up the coach and build your air up. Once it reaches full air, shut off the coach and push the button in to release the parking brakes - watch your air gauge. It should drop a few pounds and then stop. If it keeps dropping it is probably a leak at a brake chamber. When you stop for the night Lenny, you have your brake applied (button out). When you drive down the road, you have your brakes released (button in). We are checking for an airleak when the parking brakes are released. Tell me what happens and we'll go from there. I am trying to determine if you have an airleak on the emergency side (parking brake released) of the air system. When the button is out (like when you park for the night) there is no air going to the brakes. A lack of air psi applies the parking brake. No air, brakes locked up. When the button is in, the air releases a massive spring from within the brake chamber. Air psi pushes this big spring away from applying the foundation brakes. If you look at each wheel position, you'll notice that the rear brake chamber has 2 airlines going to it. When you release the brakes (push button in) air goes into the back side of the chamber to push this spring away from applying the brakes. When you step on the brake pedal, air psi goes to the other side of the chamber and applies the service side of the brake chamber.

| |||||||||||||||

| ||||||||||||||||

"5+ Years of Active Membership"  |

My bet is the same as Bill NY Bad brake chamber. Air pressure releases the brakes.. Brakes on when parked doesn't take air. so doesn't (leak) use air. You can put in a new diafram but a little dangrous if you don't know how. | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

The air is actually blowing off an airdryer purge. Once it reaches, in your case 110 lbs, the air governor sends a signal to the purge port of the dryer and blows the moisture out of the air system. This same psi signal tells the compressor to stop building up. This is what you're hearing when you say "I can hear the air release when at idle and my tanks are at 110." Once the psi drops by 20lbs, the governor closes and then stops sending air psi to the compressor. A lack of air going down this line forces the valves to seat and the compressor starts to builds psi again.

| |||||||||||||||

| ||||||||||||||||

1/11 1/11 |

well I got the air up to 110 lbs turned off the engine .when I released the brakes it dropped about 5 lbs and stayed there.at 105 for at least 10 min . I went around under the coach and heard no leaks.could it be the air bags? or is that a different system ?. lenny lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

Well, that settles that, not a brake chamber going bad on the emergency side then. Do you try to step on the brakes to see if it leaks while using the foot pedal? This is called a "Service Side Brake Application" airleak test. Test 2) Build up the air psi, shut off the coach, turn key back on, do not start the engine. Do you have an air leak with the key on? Yes or No??? Yes, you might have a bad bag. When parked the bag settles to a height that doesn't have the hole in it. When bouncing down the highway the bag flexes, it extends/contracts. If there is a crack/hole farther up the bellows it might not leak when parked because the base is covering the crack/hole. Maybe, you have a bad height control valve that pisses air out when the arm is extended or retracted?

| |||||||||||||||

| ||||||||||||||||

1/11 1/11 |

thanks Is it connected to the air compressor or do they have another one? There is one up front on the right side of the gen or is that for the horns? lenny ps. could I put some sealer on the bag like roof coating? lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

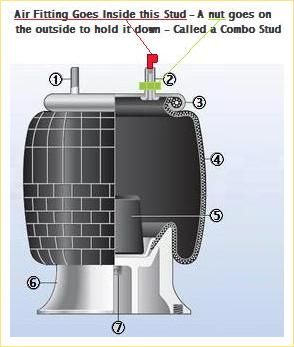

I wouldn't use a sealer on or in the bags. We need to test as to where the problem is. Right now, if a bag is suspect, what you need to do is disconnect each airline at each bag and put a schrader valve into each combo stud.  Schrader Valve - pipe thread to air chuck fitting. Install this valve into the airbag This would go where the RED FITTING is in the above drawing.  Put enough air in each bag to level the coach out at its normal drive height. Cap off airlines at each bag. Go for a ride and see which bag doesn't hold air. That will be the one that needs replacement. If you do this, make sure you have a hose to refill the leaking bag so you can get home without damaging your driveline. Or, just hook your airlines back up to your airbags and drive home. The really adventurous among us would probably take 2 containers of tire sealer in a can to refill the blown bag - you know, just to see if the tire sealer would work on it. (I know what I said earlier My issue with most tire sealer is its inherent dangerous characteristics of exploding if a spark hits the combustive gases and sealers compound. Tire guys have been known to get hurt when a tire explodes from dismount. Customer uses sealant to drive with a leaking tire - doesn't tell the tire guy - accident happens. Make sure if you do this, and the bag has to come out because it didn't work, you show the mechanic who takes the bag off the empty can of what you used to fill the tire with.

| |||||||||||||||

| ||||||||||||||||

| First Month Member |

Nifty valve. My boat could use a coupla those. Who sells them?

When I first bought my Barth, I took the tag bags out and put some 3M EC-776 in each one and sloshed it around every few hours with a coupla pounds of air pressure in it. Did that for a few days, drained them of any extra sealant and purged them for a few more days to be sure the volatiles were fully evaporated before reinstalling. Still pretty leak-free, but I am still holding my breath, even years later.

776 smells like it might have an MEK or similar solvent, so it could indeed be explosive, despite my purging. But maybe not after all these years. In any case, my exhaust has side dumps ahead of the drive axle, so I think my tag bags are fairly safe. . 84 30T PeeThirty-Something, 502 powered | |||

|

1/11 1/11 |

ok next test Monday. Also got new seats coming in and couch redone. lenny lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

1/11 1/11 |

by the way the tire I hit did hit the air bag and ripped some rubber off did cut that off. lenny lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

I still think that it sounds like the popoff valve on his air dryer,....if he has one. | ||||

|

1/11 1/11 |

did not get out today .wife work lenny family coming in lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.