Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

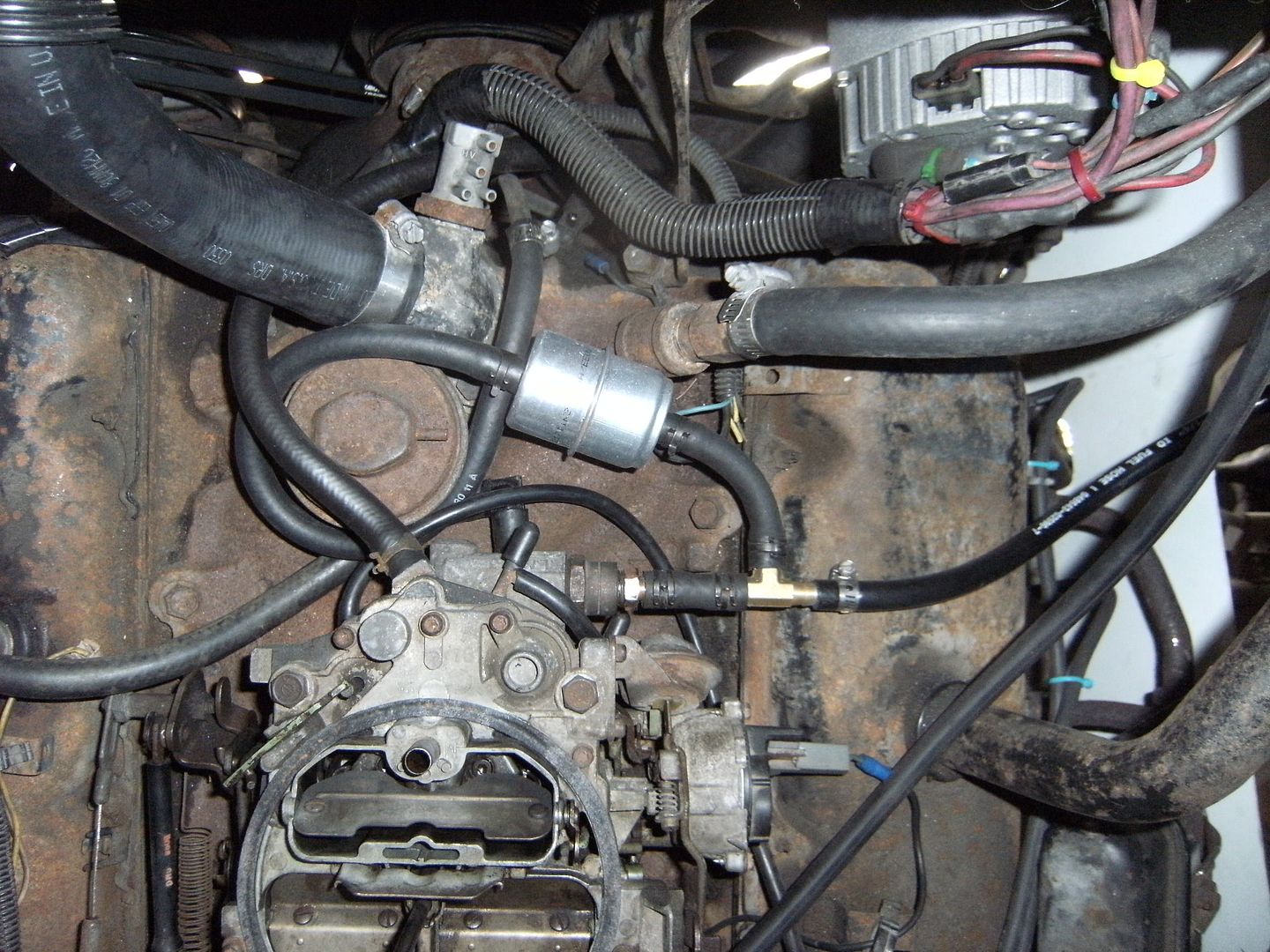

My 454 has a GM #17085212 original carburetor AKA Rochester Quadrajet. In addition to having sealed idle jet adjustments, they are also known for gas leaks in the carb base. Driving home from Florida last year, the tiny filter inside the carburetor inlet plugged and required replacement. This requires removing the usually rusted steel line, removing the carb inlet fitting with easily stripped fine threads just to replace a filter that will plug again quickly. I wanted something bigger and easier to inspect/change. Also wanted a fuel pressure gauge to monitor and diagnose fuel problems. Remove the linkages, fuel line, carb heater wire, vacuum hoses. 4 bolts and the carb is out.  Ready for transplant doctor:  I cleaned off the carb, removed the inlet filter (sorry forgot to show in photo) new top and bottom gaskets. (View from front of carb, hose is PCV valve) Removed caps covering idle adjustments (couldn't get good closeup photo of carb base)  Replaced the input line with a brass tee fitting with reducer leg for pressure gauge. (Prototype)  Final version: Metal filter, I don't trust plastic here. Installed filter in fuel line. Fuel pressure gauge is mounted in the dash panel where AM/FM radio was.  I'm still planning to rebuild the carb but I want to get the gaskets and parts kit before I open it up. (Later project) 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | ||

|

"Host" of Barthmobile.com 1/19 1/19 |

Are you sure about this? I would think running a fuel line into the cab of any vehicle wouldn't be very high on the list of things I would do. Perhaps a nice electric sending unit and gauge, made for this application, would be better.

| |||||||||||||||

| ||||||||||||||||

Official Barth Junkie |

Very good questions... I considered the "fuel in cockpit" thing and still went this route. 1. I have always had a problem with "electric anything, gauge or pump, etc" and "fuel" in the same label. (except maybe spark plug?) 2. I have a problem with electric gauges in general esp. in marine and vehicle systems... Have seen a few electric oil pressure gauges fail resulting in severe engine damage, exactly what they are supposed to prevent but can actually give false security. I know of 2 engines fried this way. This has been esp bad in marine stuff but my Barth oil gauge jumps around between 60-80 for example. Wires are good, check for power, sender check next, then maybe gauge? See my point? Shunt ammeters are great to measure 50 amps with 50 milliamps but if even a few milliamps lost through the gauge harness and there goes precision. Old fashioned mechanical gauges keep working even when the power is off... oil pressure, bulb type temp gauges, heavy inline ammeters, ah yes the good old days of tractor and old boats. Call me stubborn and old fashioned...when everything electrical fails in my boat (and plane) and GPS satellites are down the compass still works and I know how to use it. (BTW all the gauges in my plane are mechanical, still working since 1968, no bad connections, etc.) 3. My fuel system runs 6-8 psi. Not 30-50 like fuel injected. 4. The fuel line just runs out of the doghouse almost vertically to the panel above. (short run) Final version will be metal line from carb tee on. (see above, slight overkill except for heat/abrasion) 5. Key word here is "reducer tee" The leg going to the fuel gauge is about .030 inch hole I drilled after I soldered the leg closed. Should limit flow if line fails. (should have said this, thanks) 6. Lazy factor: didn't have to run fuse, power wire, sender wire. etc. 7. Mechanical gauge is cheaper. Good concerns to consider but I like the gauge info and the filter is easy to change. I am stupid and mechanical but I'm reliable! PS nice new signature line! 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

FKA: noble97monarch 3/12 3/12 |

Use one of these for the best of both worlds. http://merlinmotorsport.co.uk/...uage=en¤cy=USD  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

Official Barth Junkie |

Very cool! Perfect compromise. (Dam, there goes another 40 bucks. ) Thanks Corey? 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

Steve VW, I have several more reasons for you to consider the use of the electrical pressure gauge in the cockpit area. - I've seen hot rodders use a mechanical gauge, but only plumbed in the fuel line at the carb for use during tuning procedures - Your chassis has several locations of interest for fuel pressure readings, (1) at the carb, (2) at the inlet to the mechanical fuel pump on the engine, (3) at the inlet to the pressure regulator adjacent to the fuel tank Having one location for monitoring will only tell you that you have a fuel problem. You will still have to diagnose if it is with the mechanical fuel pump, the 25' of fuel lines, the pressure regulator, the electric fuel pump, or the gas tank pick up tubes. With an electrical guage you could have an electrical switch pick which location is monitored. >my Barth oil gauge jumps around between 60-80 for example What brand do you have? My stock GM gauge stayed at 60 psi, even with the engine off. I replaced it with VDO, electrical. >I have always had a problem with "electric anything, gauge or pump, etc" and "fuel" in the same label. That is quite reasonable to consider, but you already have an electrical pump in your gas tank if your '86 is like my '87 built on 11/86. The key though, is to keep fuel and oxygen away from an ignition source. Happy motoring, Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

Official Barth Junkie |

Actually, I can diagnose quite a bit from one point..if I power up without starting I can check the electric pump pressure from either tank. After starting I can see pressure from the mechanical pump. Standard readings will give me comparisons for filter pressure drop, as they begin to clog pressures will drop giving me time to intervene before power drops out. We're talking about 2 feet of fuel line here, less than 2 ft from the inside of the doghouse. Would you guys be happier if I mounted the gauge inside the doghouse, through the cover? I'm not telling anyone to do this...but I drove 1500 miles here and learned more about the fuel system than I ever could have known. (For instance electric pump in tank 1 has lower pressure than tank 2) I definitely don't like electric pumps in gas tanks but no good remote mechanical in tank pumps exist. I have the stock GM oil gauge.. I strongly suspect the sender since they are crude variable resistor types (not solid state like some newer stuff.) One of these days I'll hook up a different gauge temporarily to find out. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

No, we wouldn't. All we're saying is consider the other options available to you. I would never run a mechanical fuel psi gauge inside the cab of anything. Each fitting, length of hose, clamp and bulkhead passageway are potential areas of heightened concern. I'll go one step further, I wouldn't (But I have in the past) run a rubber line from the mechanical pump to the inlet fitting of the carb... But, that's just me. Perhaps you could consider a braided line for that journey? Maybe a steel line as was originally intended? Too many times I've seen hose clamps crush the rubber and cause fuel to drip out from around the clamps. There are special clamps made for rubber lines, they are protected to minimize the potential for the rubber to be crushed or split open on the sharp edge, or the worm gear opening, of the clamp. Rubber hoses, if not of the right stuff, can suck shut or balloon outward depending on which side of the pump it's on. Rubber will also swell/crack from repeated heating and cool downs. Yes, I know, the factory used... or at least "Did Use" rubber hoses and clamps for their connections. The operable word is in the past tense form. They "Did Use" these connections and only for very short runs. No modern company has ever installed a mechanical factory fuel psi gauge inside the cab of any vehicle driven down the road that I'm aware of. NASCAR doesn't even use a mechanical fuel psi gauge inside their cars. I realize that this makes it less likely you'll post pictures of your projects in the future. Chances are others will feel intimidated and maybe not want to post pictures of their upgrades too. I get it - No one wants to be told "Whoa there!!!" But, if I was to ignore this post and not tell you of my concerns then I wouldn't feel right either. I hope you take my concerns for what they're intended - real concerns about what you're doing.

| |||||||||||||||

| ||||||||||||||||

Glassnose Aficionado |

Steve, do you know where the oil pressure sending unit is located? Mine is pegged out when I turn the key on and stays that way except when the key is off. I assume a short or open connection, but I can't find the sending unit to begin analyzing it. 79 Barth Classic | |||

|

Official Barth Junkie |

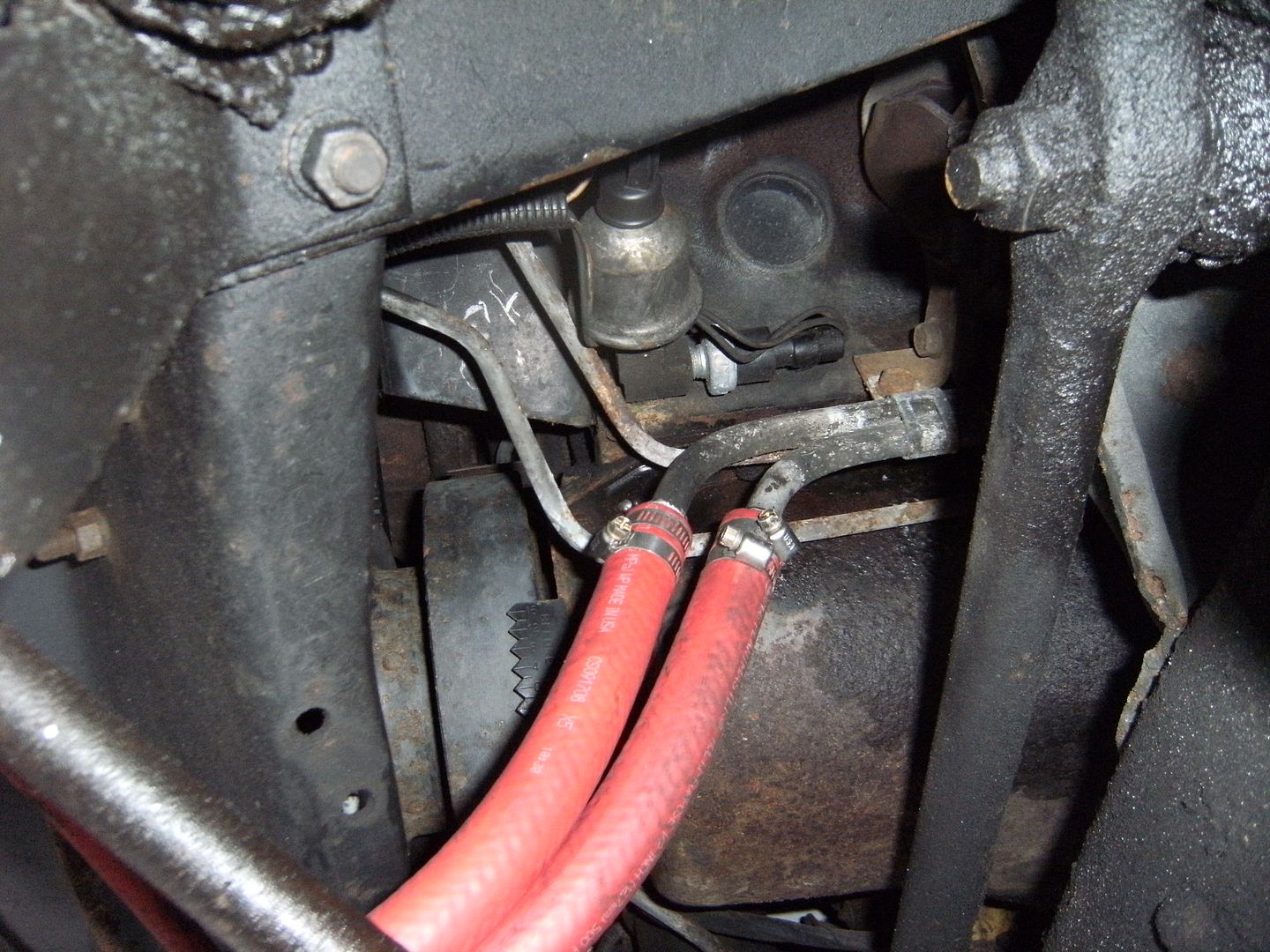

Don't worry Bill. I fully expected some feedback on this! (I'm like something you stepped in, you can't just shake it off, you gotta scrape it!) In my defense, none of the arguments given were new to me, but I should have included more rationale (pro and con) to let the reader be aware and choose wisely. Bottom line: I'm talking a 5-6 psi system, in a well maintained, routinely inspected doghouse. There are better ways to do this, of course, all the way to hydraulic braided AN flare fittings. (or even electric I have factory rubber lines on each tank, others connecting to the fuel selector valve, connecting the inline chassis fuel filter, and connecting both sides of the mechanical fuel pump. All are subject to the same limitations on age, etc. I have simply added 2-3 more feet to the collection to be inspected and maintained. (albeit in a contentious location One reason the factories "did use" hose was they were still low psi. Everything from 80's on is fuelie with 30 psi or much more, same for racers. New ballpark indeed. I'm OK with it in my rig, didn't mean to imply this is perfect for all. Just wanted to let people even see what a carb looks like, etc. I'm flattered to have provoked such quality response. It is the most valuable asset of this site, and I don't mind cranking you guys up so we all get the straight stuff. This all started for me with those puny carburetor inlet filters. Everyone agrees they are a PITA, but what to do about it? This is just one way to do that. Now you guys just get back to the important stuff like DP vs gasser and I'll be OK, (or high wing vs low wing, straight weight oil vs multivis...) Danny: the senders are located low on the driver side of engine block, well forward. Mine has a tee with a pressure switch and the pressure sender. Next time I crawl under I'll see if I can get the camera in there. Dang, I just was down there yesterday playing with timing. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Official Barth Junkie |

OK Danny you made me do it..  The big shiny one is for gauge, the smaller is a switch, I think. Haven't checked with meter to be sure yet. You can see the bottom timing marks too. (Oh jeez, Bill's gonna bust me for the clamps) 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Glassnose Aficionado |

Thanks Steve, found it. Disconnect wire, still pegged, ground to frame drops to middle. Wire fraid at connector so cut and replaced spade. Reconnect, still pegged when key on, start engine no change. So, open circuit gauge pegs, gauge pegged when connected to sender, sender open-no good. Need new sender? Am I thinking right? Sorry about the hi-jack, if this goes on I'll start a new thread. 79 Barth Classic | |||

|

Official Barth Junkie |

Probably bad sender. Check when running at pressure?.. if no change, sender for sure. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Glassnose Aficionado |

Good, just one more stupid question. When I remove the sender will oil drain out? I think I'll put in the splitter and an idiot light sender and hook up the LED bar Lenny gave me for the dash. Bill or Rusty, feel free to make this conversation a seperate thread for future refence. 79 Barth Classic | |||

|

Official Barth Junkie |

Small amount will run out, maybe couple spoonfuls or so. Rag should do, poke in hole if needed. Of course if the engine is running.. Good luck with the new gauge. I'm planning to replace my sender soon. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.