Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

"Host" of Barthmobile.com 1/19 1/19 |

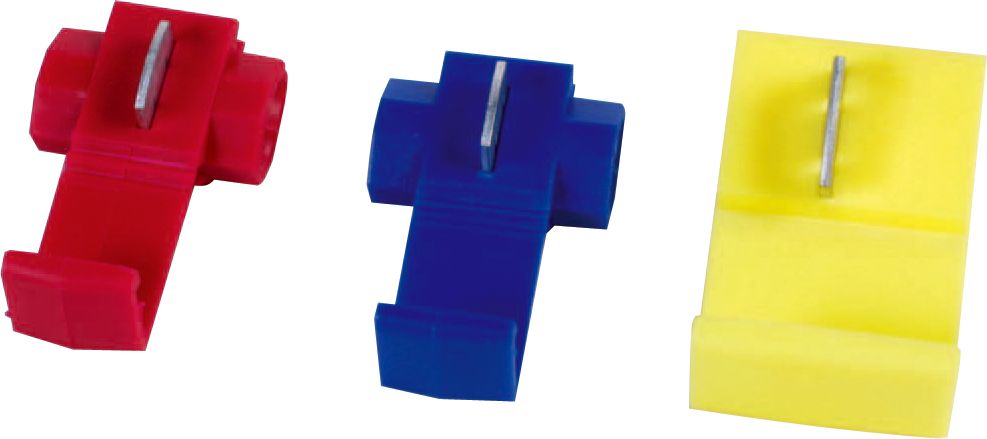

I have found several wirenuts and non-sealed butt connectors under my chassis and thought I would share something with you. A wire nut setup is a fast way of hooking up a wire. Anything that is hooked like this is subjected to heavy corrosion and vibration. These are made for house wiring.  A regular butt connector can allow moisture in it - even if sealed with electrical tape.  If you find a twist lock wire connector or regular butt connector you should replace it with butt connectors that have a heat shrink attached to it. After crimping you heat up the connection with a cigarette lighter, propane torch or heat gun. The heat shrink melts around the connection and keeps out moisture and also holds the wire better.  Adhesive Lined Heat Shrink Butt Connectors Environmentally-sealed splicing Wire Range - Color 22-18 gauge - Red 16-14 gauge - Blue 12-10 gauge - Yellow This is what I use on truck wiring under the chassis or at anything that is not inside the cab. I also use this inside the cab but this is not as critical. Wiring connectors with dielectric grease could run out or get power washed away and do not provide 100% sealing against the elements. Short of splicing with solder and flux and then adding heatshrink to it, this is the better way of doing it. Reasons why wiring fails and rots away...The wire has power to it most of the time. The water was sprayed up there by roadspray. The connection has moisture in it. The green stuff inside of a failed wire is just a rotted copper wire that was sped up by the addition of water & electrical current. This is called "galvanic action" and should be avoided at all cost. Galvanic Action: An action of electropositive and electronegative metals due to the wasting away of the positive metal. This happens when copper is in contact with water or worst yet salt water. What this means is the positive current in the wire reacts with the rain, salt, calcium-chloride etc... this makes the power drain out by connection it to (negative) ground. The reaction eats away at the live wire until it rots away & breaks. Proper 12v Wiring Connectors For Outside Conditions  7/3/10: Repaired several bad image links

| ||||||||||||||

| |||||||||||||||

4/08 4/08"5+ Years of Active Membership" |

Bill, This is an excellent post, and typical of the pertenant and usefull info you give us. Could you recommend a resource for "Adhesive Lined Heat Shrink Butt Connectors"? Thanks, Bill G | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

I buy in bulk from Imperial out of Green Bay, WI. You can purchase these from several local sources. Napa, AutoZone, Pep Boys any good automotive parts house. Ask for "Butt-connectors with HeatShrink" Do not get the "Soldered Terminal" design as these tend to run again and overheat. What these are is a low heat melting solder that is built into the connector - when you heat these to melt the heatshrink some of the center section melts into the wire and makes for a better initial contact. The keyword here is "Initial" If there is a heavy load placed on the wire the solder could start to run again and pull the wire apart. Also stay away from the "Snap Lock" style connectors. These are connectors that you lay over a wire and then attach another wire to it and crimp. There is no splicing or wire prep work involved and some of them have a dab of grease in it.  So Bill, what do I do with all of my older connectors? Save them and If you must use them, do so "inside" your coach. I haven't changed many of my "Quick Lock" or "non-heatshrink" connectors in my dash and unless there's a problem I will just leave them alone. I did however remove as many wire nuts as a could find as these could vibrate loose. 7/3/10: Repair bad image link

| |||||||||||||||

| ||||||||||||||||

Captain Doom |

Do you have a URL or link for Imperial? My local NAPA stores don't carry these anymore... Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

Captain Doom |

Never mind - I found it: http://www.imperialsupplies.com/grp101.shtml They'd better offer a special discount for the Packers' win-loss record (I've been a fan since '55...) Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

"Host" of Barthmobile.com 1/19 1/19 |

I have to place an order of $300.00 or more to get free shipping. I don't know if they will sell to an individual. Odd, I have bought these from Napa in the past... 71896 red 18-22ga 50 pieces min. 71897 blue 16-14ga 50 pieces min. 71898 yellow 12-10ga 25 pieces min. www.Imperialinc.com

| |||||||||||||||

| ||||||||||||||||

"Host" of Barthmobile.com 1/19 1/19 |

I just got an email that stated... "I have seen ECM wiring fail in as little as two days" Bill, how can you make such a statement? For the benefit of all here's the answer. Take a 12ga or 14ga wire. Now strip it back to give a 360 degree opening for moisture to get into it. Hook the wire up to something that takes power all of the time (like ECM wiring) and place it next to anything that is a ground. What happens this time of the year is the salt water, calcium chloride or even plain water gets into the wire and the current starts to leach out into the metal ground. Because it is now "shorting out" it starts to eat away at the wire. The closer it is to a ground the faster this happens. I recently chased a shutdown truck and found the problem by the driver simply stating "two days ago another mechanic chased me and repaired a wire by the starter". Upon further examination I found that the wire had a regular butt connector on it and the mechanic zip tied it to a U-bolt. The new butt connector had a severely corroded wire that was no longer attached to the new butt connector. On the outside of your coach you need to protect your wiring with sealed connectors. Use a small dab of regular or dielectric grease inside your fuse holders and place it on the blades of your fuses. If you have a relay that is hanging down then zip tie it up to allow the water to run down the wire and not into the relay. Use the same method to protect relays like you would a fuse. Use a battery protectant spray on the battery terminals, starter studs and the back of the alternator. If you have a main battery shutdown then use it. The least amount of time that the wire is leaching the longer it will last. On Fords with an EFI and an electrical fuel pump (my Barth) the relays for the ECM feed and the fuel pump were both sitting behind the right front headlight hanging upside down by the wiring. I removed both relays and found heavy corrosion inside. I popped out the wires and cleaned the terminals inside of the harness. Installed two new relays with dielectric grease and then zip tied these up to allow moisture to run off. If you own a Barth like mine look for those relays and check on them.

| |||||||||||||||

| ||||||||||||||||

"Host" of Barthmobile.com 1/19 1/19 |

In case you are having a problem finding those heat shrink butt connectors here is a link I just found.  Heat Shrink Connector Starter Kit SBA5002 Krimpa-Seal Assortment 20 items 115 pieces 48.95 7/3/2010 Edit: updated the outdated link & image.

| |||||||||||||||

| ||||||||||||||||

Captain Doom |

Bill, you do good work! I'd add that if one wants to solder connections, the ends of the two wires should be twisted, then bent into a "J"; the two "J"s should be hooked together, pinched, then soldered. Using heat shrink tubing is always a good idea (obviously, this has to go onto one of the wires before connecting. ONLY rosin-core solder should be used, and a flux remover should be applied when cool (acid core solder will cause corrosion quickly, and even rosin core, untreated, will eventually). The joint should be coated with grease (I use Super Lube [Teflon] Grease) before the heatshrink is positioned and shrunk. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

| First Month Member |

A double J connection has a potential failure point where the Js loop around each other. The joint has very little mechanical integrity without the solder. A soldered connection is better if it does not depend on the solder for strength. A Western Union splice is very strong on its own, and is much stronger after the soldering. . 84 30T PeeThirty-Something, 502 powered | |||

|

| First Month Member |

Yeah. It's obvious. But why do I keep forgetting to do it? DANG! Did it again! . 84 30T PeeThirty-Something, 502 powered | |||

|

Captain Doom |

I agree - but wires should be bundled and supported so mechanical strength isn't dependent on the soldered joint (same for crimped connections). Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

| First Month Member |

Looking back, I may have been a little too nit-picky here. Barths don't have the vibration that jets do. Vibration will work-harden solder joints and cause almost undetectable junctions that can actually act like a diode. Chasing those has driven me crazy. Returning to the butt splices, I use a regular butt splice and then work a little shoe goo or one of the Goop products into each end. This is not better than the ones Bill mentions, but it allows me to use the butt splices I already have in stock, or can conveniently buy. If the splice is in a road spray area, I take the additional step of covering the whole thing with shrink tubing. . 84 30T PeeThirty-Something, 502 powered | |||

|

|

RE: double J connection has a potential failure point where the Js loop around each other. The joint has very little mechanical integrity without the solder. A soldered connection is better if it does not depend on the solder for strength. A Western Union splice is very strong on its own, and is much stronger after the soldering. ok what is a 'Western Union Splice' ?? _________________________ The 82 MCC {by Barth} is not an rv-- it is a Motor Coach!! | |||

|

| First Month Member |

A method of twisting two wires together before soldering, to make a mechanically strong joint. The wire itself forms an inherently strong joint, so the solder serves only to enhance conductivity and keep corrosion out, and is subject to little or no mechanical stress. It was originally designed for use by, guess who, Western Union, so their telegraph lines could stand the stress of being pulled on by gravity and wiggled by the wind. We used it on airplanes when we had to solder a joint. It had the advantages of being resistant to vibration-induced solder failure and was very compact, lending itself to easy pulling and insulation, as well as being very neat and easy to stagger. Typically, we used liquid electrical tape and shrink tubing. http://www.tpub.com/content/construction/14027/css/14027_122.htm . 84 30T PeeThirty-Something, 502 powered | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.