Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

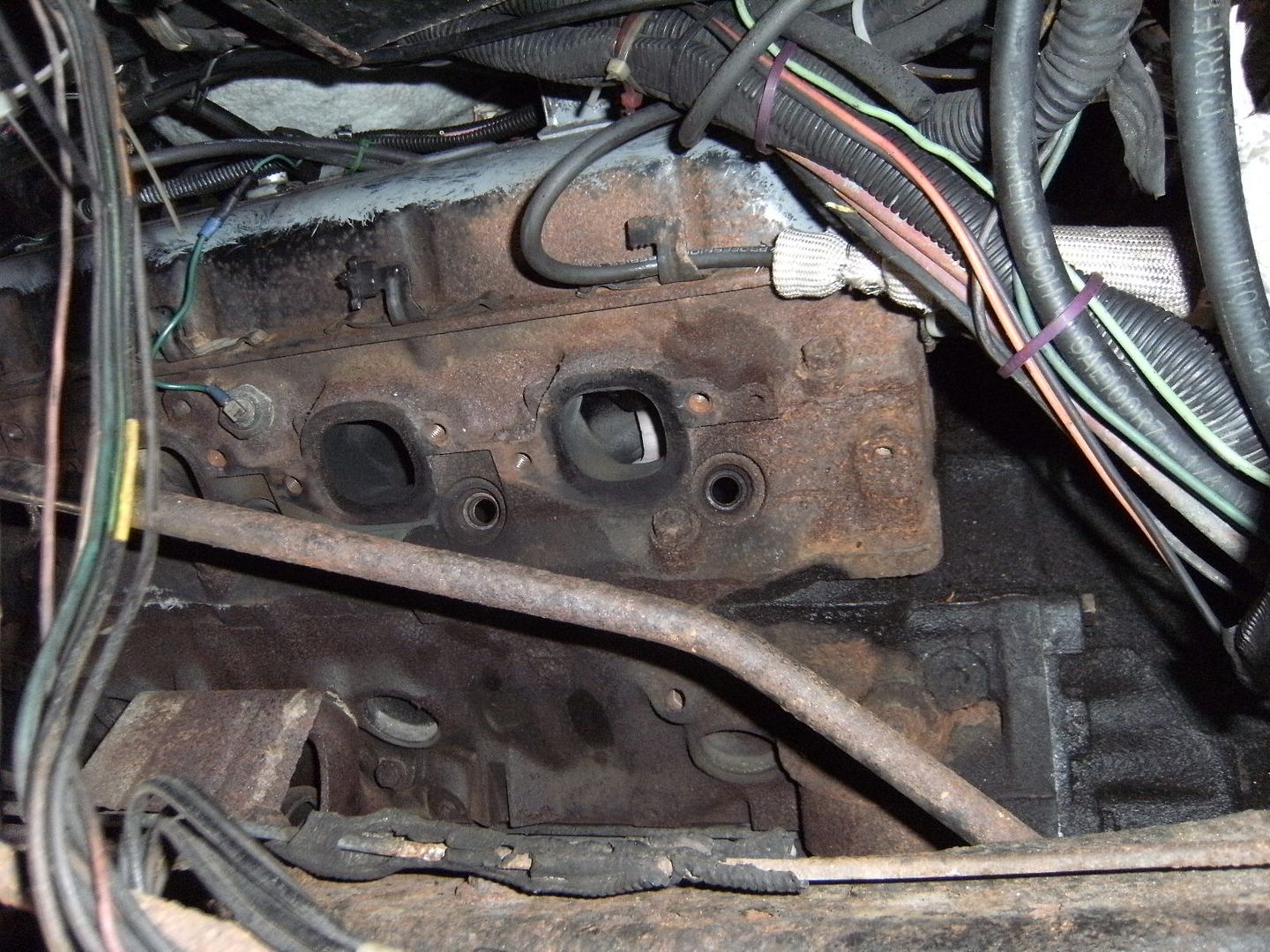

I finally got around to degreasing my engine to chase down some oil leaks. Funny thing is I found the one isn't an oil leak but rather a drippy fuel pump that was just getting so greasy that it looked like oil. While using 4 cans of degreaser gel and hosing the engine down I seemed to have lost my temp gauge, doesn't read anything so I'm thinking I must have dislodged the connector. Can't find the sensor anywhere though. Any ideas where I should be looking? | |||

|

Official Barth Junkie |

Mine is low on the side of the driver's cylinder head. Slip on wire connector. Easy to dislodge.  9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Yup, found it down there, didn't think it would be there, I was thinking on the intake. Now just need to wait for my new fuel pump and see if retorquing the oil pan bolts (or at least all the ones I could get at) takes care of my pesky oil leaks. At least now I should be able to see where they are coming from. That boat anchor was filthy. | ||||

|

Any good suggestions for how to rotate the engine without pulling the front dog box off in case the pushrod is down when I replace the pump? | ||||

|

Official Barth Junkie |

Just bump it over a bit with the starter. Might take a few tries should be close enough. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

When I replaced my fuel pump, I found the hardest part was to keep the push rod in the engine, U-tube has several suggestions on how to hold it up, I used a thin strip of plastic, pulled it out right before I tightened the bolts. | |||

|

3/23 3/23 |

Some I know use a bit of grease on a cold engine. I had a failure around the 5 mile point on the Illinois River on the way to Lake Michigan. This was not the place to wait for the engine to cool. I used a thumbnail piece of toilet paper to shim/wedge the rod in place. The paper will wash into the engine oil get to the filter. No problems 500 engine hours later. | |||

|

3/23 3/23 |

CCC what a good idea, even on my cold engine the grease did not work, that doggone push rod is just to heavy. | |||

|

I have watched the entries about the fuel pump on a Chevy Big Block. Please see - http://www.fmcowners.com/mbbs2...ails.asp?albumid=100 (I used an engine with the timing chain cover removed for the pictures to illustrate just what you are doing "inside" the hole where the fuel pump mounts) The 440 Chrysler and 454 Chevy have almost identical fuel pump mounts. The issue with the pump pushrod sliding down are identical. First the pushrod must be on the ROUND base circle of the cam. Tap the starter (coil wire grounded) and push up on the pushrod till you are sure it is all the way UP IN THE HOLE. Yes, tapping the starter to rotate the engine while doing something on the engine might take two people, but unless you have a remote starter switch (that every mechanic's tool box should have), I'll leave that up to you. Working thru the pump mount hole, let the pushrod come down about and inch or more, then put a BIG GOB of HEAVY WEIGHT WHEEL BEARING GREASE on the pushrod and slowly push it back up in the hole, where it should stay. If it won't stay up in there . . . you didn't use enough grease ! Then, making sure you put the gasket to the pump flange, install the pump. Just at the very end, it takes a little squeeze of the pump body to get it flush with the flange as the pump arm contacts the pushrod. Then bolts in the holes and tighten. I have changed several 454 pumps and this process works. (The Chevy small block has a threaded bolt hole in the front of the block that can take a longer bolt which sticks in and contacts the side of the pushrod to hold it when changing the fuel pump. If you do a SB Chevy pump, don't tighten that bolt too tight as it will bend the pushrod) Of course the pictures in the Link were taken of an engine on a floor stand. Frame rails, hoses, all kinds of other stuff will be in the way . . . but the pictures do show what it takes to hold that cursed pushrod up in the hole. Too hard ? Then tow it to a shop that will charge about $150 or more an hour to do the exact same thing in the pics. Pump ON ! Lou FMC #120 ps: remote starter switch - https://www.google.com/search?...ceid=chrome&ie=UTF-8 | ||||

|

3/23 3/23 |

I really am leery of using the wheel bearing grease. The additives must be washed into the oil and they are so very different in materials used that I would not want them anywhere near my main and cam bearings. Not sure if the technology has changed that much in the near half century I have been out of the business but a good deal of the viscosity and additive carrier was gained by use of micro-fine ground clay. Wheel bearings are "rollers" and not "sliders". If using this method I think I would look to an oil and filter change within a couple of hundred miles followed by another within an additional 500. I'll stick with a trip to the bathroom and have faith in the filter. | |||

|

Sorry to have bothered you. Adios, Lou | ||||

|

8/19 8/19 |

Interesting, Tim! I hope Rusty has internet and time for comment after Hurricane Irma. Rusty's Knowledge of the oil industry is always useful here.

| |||

|

Official Barth Junkie |

I doubt that they are still using clay to thicken. Molydisulfide, lithium soaps, aluminum complex additives are used to change the melting point but I don't think current additives would be harmful in small amounts diluted in the motor oil. Rusty will tell all I hope! 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Lou, don't get pissed, we all have opinions, and hopefully one will work for the individual doing the job. Only congress does not listen to the opposing side ....hee hee!!! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.