Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

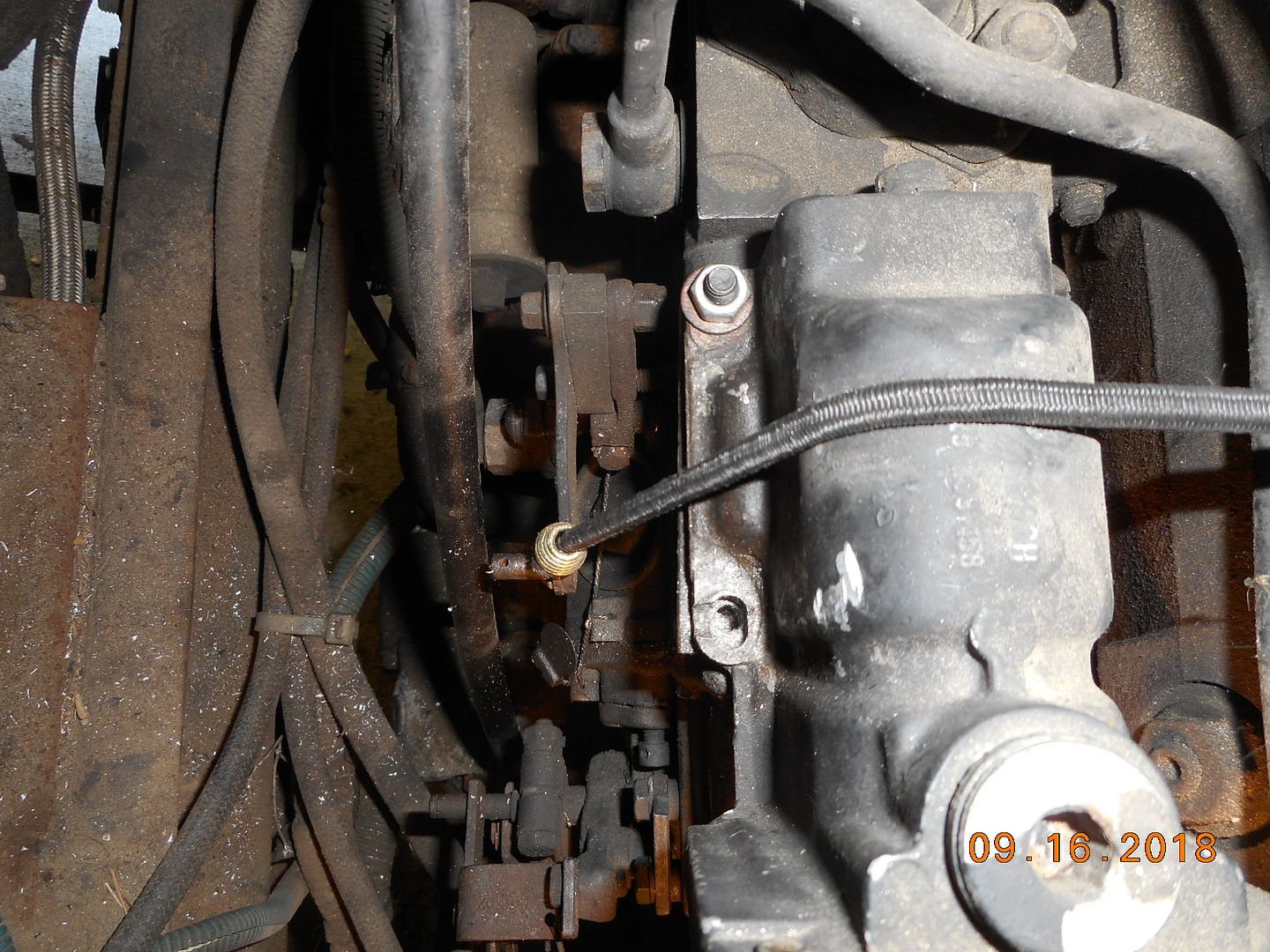

Things may be slow here on the site but for me, never a dull moment. On the way through Knoxville traffic (why don't these things ever happen out in the country?) I lost most of the engine power. Ended up limping to an exit at 35 mph. Made it to a gas station to figure out what was wrong. Looked in the engine bay... there's your problem! There is a fuel shut off solenoid mounted on the injector pump. It is supposed to open the fuel valve while running and close the valve to shut it down. It was hanging loose and sideways! (Actually I was lucky it didn't drop a little further and shut the fuel off completely) The mounting bracket had failed. One bolt broken, one ear broken off. The remaining holes were worn out of round. Thanks to my heroes at Cummins, there is a part number stamped into the bottom of the bracket. (3965494 as you can see)  I removed the solenoid and bracket, tied the valve open with a piece of string and drove on. When I got home I ordered a new bracket on Ebay. 4 days and only $20 later I have the new backet.  I still have to remove the broken bolt from the engine pump. FWIW, this is similar but not the same setup as the 5.9 Cummins. This solenoid is part #3936026 (with 3" bolt spacing). It has a 3 wire electrical plug. (The 5.9 solenoid has 2.5" bolt spacing.) It is up to 37 today but I may wait a while to reinstall. I may use a small bungee cord to hold the valve open until I get back to warm climes. Then I will also show pics of where it belongs on the engine. Have Barth, will travel 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | ||

|

I had a problem with the solenoid today. Turned the key to start and when I released the key the engine died. Repeated about 6 times and it finally held and didn't fail again. These things have one circuit to pull in and another circuit to hold in. That's why 3 wires. I'll be carrying a bungee cord myself for a while. 1993 34 Regency WB 8.3 Cummins 300HP | ||||

|

Official Barth Junkie |

On my Spartan, the pick winding runs from the starter and the hold winding is tied to one of the switched circuit breakers on the rear power panel. Check those connections. Since it is on the switched power buss, you may have a similar relay problem to mine. The pick winding is powered by the starting circuit. The hold winding is powered through the rear master relay...  You can see at the top there are 2 sets of breakers. Immediate left is the master switch. Just to the right of that, terminals sticking up, is the rear master relay. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Thanks for the tip. Heading South first thing in the AM. If it acts up again I'll get out the test light and check that circuit. 1993 34 Regency WB 8.3 Cummins 300HP | ||||

|

I had a similar problem months ago, engine would start but would stop when the key returned to run position. Problem was a sticking solenoid, the pull in winding had enough power to move the fuel control just enough to start but not far enough for the run winding to hold in. I turned the key on to the run position and then went back and manually pulled up the solenoid. It did stay and then I went back to the front and started the engine. When I got back home, I cleaned the solenoid area and lubricated all the levers, no problem since. Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

Official Barth Junkie |

Notice the labels (upside down) on the 4 breakers on the far right (switched) buss. Far right: air dryer next: FUEL SOLENOID then: Back up/low coolant then: ignition reg (to the alternator) Check for power at that fuel solenoid breaker terminal when key is on. It should be wired straight from there to the hold winding of the solenoid. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

I see that in your picture. Looks like #35. I have the same panel. I'll try the lube job also. Thanks. All the way from Alaska with no problems. A good thing to. Not much help up in those parts. 1993 34 Regency WB 8.3 Cummins 300HP | ||||

|

Official Barth Junkie |

good luck 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

1/19 1/19 |

After help from some of our experienced members, I was able to trouble-shoot the symptoms, and discovered the "hold" coil of the fuel shutoff solenoid was inop. P/N 3919422 fuel shutoff solenoid purchased off Ebay ($32). Was somewhat skeptical as with most everything the solenoid is manufactured in China. Upon delivery, I compared it to the solenoid that had failed (looked to be an original from Cummins). I was impressed, so I ordered another to carry as a spare. 8K miles later, the solenoid is still doing the job. Is good to have the zip-ties on hand as they can be used for a variety of applications, but for the price and proven longevity, carry an extra solenoid. Is easy to replace(the most difficult part of the job is moving the mattress off the engine access box). | |||

|

Official Barth Junkie |

Finally got around to replacing the fuel solenoid and bracket. One hold down bold had broken off and another had broken off the ear of the bracket. I replaced the bracket. Also replaced the remaining bolt with a stud so I could be sure it was fully threaded into the hole and just remove the nut in the future. The broken bolt had apparently flopped around for some time before breaking and had beat up the hole pretty bad. Given the angle and location I was not looking forward to removing the stump. Steel bolt in soft aluminum casting, needs to be perfectly centered. I stalled on the job for quite some time. I used the handyman's second secret weapon (bungee cord) for some time to hold the valve open. I used a stick to push the valve down for shut off. Finally center punched the stump, drilled small hole. Soaked for a while. Tried an Easy-Out. No joy. It is a 6mm x 1.0 metric thread. Worked up to 5mm tap drill, kept it on center. I got the threads tapped out.  I installed another stud, finally got the bracket back on and the solenoid back in service.  9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.