Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

12/10 12/10 |

Well I have hit a repair that I'd like to get some advice from the pros here. As you can see from the photo, I have a street side upper shock mount that is broken. It looks like it may have been repaired once already. I was thinking about cutting off the rivets and beefing up the bracket and studs, then bolting the bracket back in with some grade 8 bolts. The hole going through the side of frame rail is no problem but the 2 upper bolts would have to go through the floor. I'm not sure about what might be in the way so I'll have to do some figuring to be sure I won't hit anything. I want to put Bilsteins on so this was going to need beefing up anyway. I was thinking about drilling a small hole through the 2 top rivets to find area in the coach then use a holesaw to get access to the top of the framerail. That way the flooring would be out of the way when I torque the bolts down. My Barth is a 1989 but the chassis is a 1985, just for the record. Here is the curb side shock mount.  This is the broken street side mount. The plumbing running along the bottom is the fuel line for the genny. I'm aware of it is there so don't anyone worry.  Regal 25 built in 1989 1985 P-30 chassis 454 TH400 | ||

|

| First Month Member |

Is there room to slide a nut on top of the frame flange? Perhaps a jam nut? Then use a bolt of just sufficient length up from the bottom. . 84 30T PeeThirty-Something, 502 powered | |||

|

FKA: noble97monarch 3/12 3/12 |

I would not mess in any way with the buck riveted perch that is there. It has stood the test of time and appears to be of a good enough design. The rod that the shock mounts to is the weak point and my guess is the previous weld repair was sub par. In fact, it looks like the weld repair did not penetrate fully from the corrosion in the break pic. It is good to have this be the weak link versus transmitting the energy into the frame. Basically, a shock is not such a huge safety item (like a tie rod or king pin)that you need to shoot for overkill. I would recommend a good welder fabricate and attach the next shock mount rod. If that is a crack I see on the existing mount, have that welded up too. Easy, effective and keeping the "fuse" in place. An additional question is why the energy is so great here. Did the shock freeze up? A good, working shock should not put huge stress on that pin.  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

| First Month Member |

My armchair observation of this picture makes me inclined to think that a really good repair would require removing the bracket so the weldor could get in back. I would consider a bolt with a head, and place it in there so the weld bead could connect the head to the inside of the bracket in as much area as possible. And, of course, some welding around the outside. PS. I do not like to weld Grade 8 bolts. Even better, I would consider welding a specially made threaded insert inside the bracket, and screwing a bolt into it for the shock. The insert would be cylindrical and counterbored to allow the bolt to enter deeply enough so that there would be no bending force on the threaded part of the bolt.

My guess, too.

That is a known weak spot on the Pee MH chassis. Bilstein used to include instructions with their shocks on how to beef it up to avoid failure. . 84 30T PeeThirty-Something, 502 powered | |||

|

FKA: noble97monarch 3/12 3/12 |

Bill, What did they recommend beefing up? The problem appears to be the rod diameter and that is fixed by the shock mount. Beefing up the frame mount would appear to have zero affect as that is not where the failure is occurring. Perhaps there is a similar shock available that has a larger diameter mounting hole on the topside. That would allow a larger rod to be welded in.  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

| First Month Member |

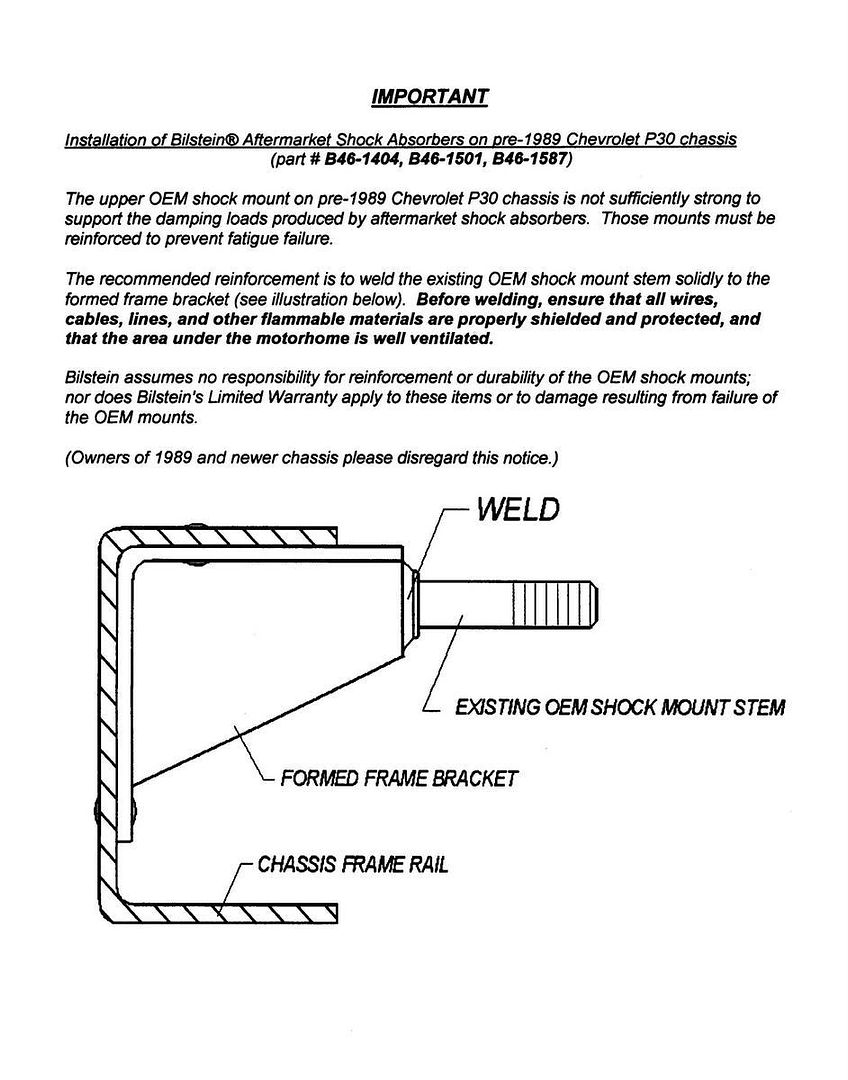

They recommended welding all around the outside juncture of the bolt and the bracket face. This was necessary on models up to 1989. Apparently the design was changed or improved around 89. However, that is a band aid for a poor design. However some Pees have brackets that do not look like the drawing on the sheet. PM me with address for a copy.

Yup. A larger diameter rod would give more area to weld and the larger diameter would make the load on the weld bead more tension and less flexion. . 84 30T PeeThirty-Something, 502 powered | |||

|

12/10 12/10 |

Bill, is this the doc you are talking about?  I have not checked the shock to see if it's frozen or not. I'll know tomorrow. I did have a friend look at it and the above document. He asked why I always have to make things so complicated. He said a bit of grinding and cleaning up and a stud welded on the bracket would hold up with no problem. It is a bit of a tight spot to work in but doable. We'll see. Regal 25 built in 1989 1985 P-30 chassis 454 TH400 | |||

|

FKA: noble97monarch 3/12 3/12 |

Did you see the part that says owners of 89 and newer to disregard? Makes me think yours will not benefit from this fix.  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

| First Month Member |

Yup.

Tell him "It's a HOBBY!"

I guess that would depend on the quality of the welding. My own inclination is, if something breaks, re-doing it the same way is chancy. However, if the re-do is better than the previous repair, it might be OK. I might be leaning a little toward overkill due to my experience with broken shock mounts on dune buggies and 4WDs. . 84 30T PeeThirty-Something, 502 powered | |||

|

Official Barth Junkie |

My 86 chassis has Bilsteins on it and the bolts are welded as in the diagram. The shocks have been there for at least 20,000 miles and the mounts appear intact. Since your 89 is actually an 85 that may be the ticket. Your previous welds look suspicious, especially in the center. My welds look much better (at least externally). Give new good welding a try before changing the mount. If it breaks again, then I'd try something else. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

12/10 12/10 |

The thing is my chassis is actually an 85 but Barth built the coach in 1989. The original owners had lots of problems due to this. The engine had all kinds of problems and GM said the chassis was out of warranty based on the serial number. I have paperwork showing how Barth went to bat for the Collins and got GM to give them the warranty starting in 89. GM ended up replacing the 454 after 30k miles. I wonder if the engine issues were related to sitting around for so long before being built. @ bill h, you crack me up! I follow what you're saying. I want this repair to be the last time I (or any future owner) has to deal with this issue. A little extra time spent now sure beats dealing with it out on the road. Regal 25 built in 1989 1985 P-30 chassis 454 TH400 | |||

|

12/10 12/10 |

I got the shock off a few days ago. It isn't frozen but it isn't a shock anymore either. It works about as good as the gas lifts on my cabinet doors. I took the broken off stud to the welder today. There is a collar with a stud welded to that. Then the collar was welded to the bracket. The collar is a cast part and he didn't like welding that back on. He turned a new collar to weld to the bracket. It has a treaded hole in it for a shock bolt. This guy builds pulling truck frames so this kind of work in right up his alley. The welder has been hard to pin down since it's harvest time and he is making his hay right now doing work for the farmers. Supposed to go in tomorrow to get fixed up. Regal 25 built in 1989 1985 P-30 chassis 454 TH400 | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.