Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

|

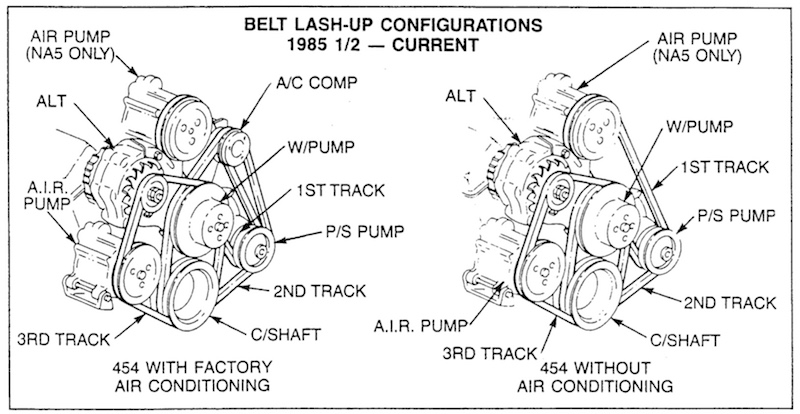

Hi, As part of my engine accessories overhaul, taking the advice of the wise men here, I also removed the secondary doghouse cover. It gives better access to the front of the engine from the top. The picture shows the type of the 454 with the 7N4 AC option, running the Sanden compressor. With access to the top of the engine, you can clearly see that the 3/8" wide belt is too small in the groove of the compressor. It looks like it is made for a half inch belt. This 3/8" belt fits fine on the associated grooves on the water pump pulley, crank pulley, and PS pump pulley. The top AIR pump is driven by a belt from another groove on the PS pump, that groove is the same width as the first groove. GM specifies a belt that is 0.47" (15/32"), and 45" long. There's a third groove on the PS pulley, and this belt only circuits the crank pulley. This groove is the same width as the other grooves in the PS pulley. GM specifies a belt that is 3/8", and 41" long. It looks like there are two sizes of belts in the narrow grooves, 3/8" and 15/32". The wide groove of the AC compressor has a 3/8". I am thinking that somewhere at GM, there was a mistake. It is either in documentation or in design. Sanden made the same compressor, intended to use 3/8" belts, in VW cars of the era. (I spent too much time with Ebay and Rockauto to figure that out) Probably most of the mechanics who have worked on this engine configuration have not been able to see the grooves on the AC compressor. These issues with the groove widths might explain why there are so many problems with the design. The 3/8" belt is riding on the base of the groove, and not on the sidewalls of the V shape. The belt wears prematurely, loosens, and the slack either leads to the belt snapping, jumping the groove, and perhaps breaking the aluminum AC compressor bracket of the 7N4 configuration. I think I'm going to look for a 15/32" belt for this. It seems tough to find belts that are accurately labeled. But in this case a 12mm width should probably work, that is 0.472". I don't want to go too wide, because the then the belt won't be seated properly in the other pulleys on the path. What a pain. But no pain, no gain? Right? Happy Motoring, Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust  | ||

|

3/23 3/23 |

Geez Matt, it is very difficult for me to believe, Chevy P30 engineers would ever make a design error, you must be mistaken!!!! Typical look at the trouble-free fuel system!! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

My 86 was a nightmare. Four belts. 3 V belts and one flat belt. Worst design I ever saw. (see attached) A single V belt from crank to power steering pump. The second groove on the power steering had a belt to drive the AC. So, power steering (and Hydroboost brakes) plus AC on one belt from the crank! Another V belt for crank to fan/water pump and air pump. Flat belt for fan, alternator and air pump. Only flat belt I have ever seen without an idler tensioner pulley. Neither air pump worked. AC was a cobbled up aftermarket unit. AC brackets did not line up that pulley with the other pulleys. Different groove sizes on crank pulley and power steering. AC was Freon 12 system, did not hold charge. I removed both air pumps, AC compressor and associated brackets. Final version was a V belt from crank to power steering. Second V belt from crank to power steering to fan. Flat belt from crank to fan to alternator. Flat belt needed constant adjustment since it had no tensioner idler. I was planning to install a tensioner when I sold it. Removing the AC and air pump brackets and mounts really improved access around the front of the engine. Good luck to anyone trying to get belts to work, especially with AC.  9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.