Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

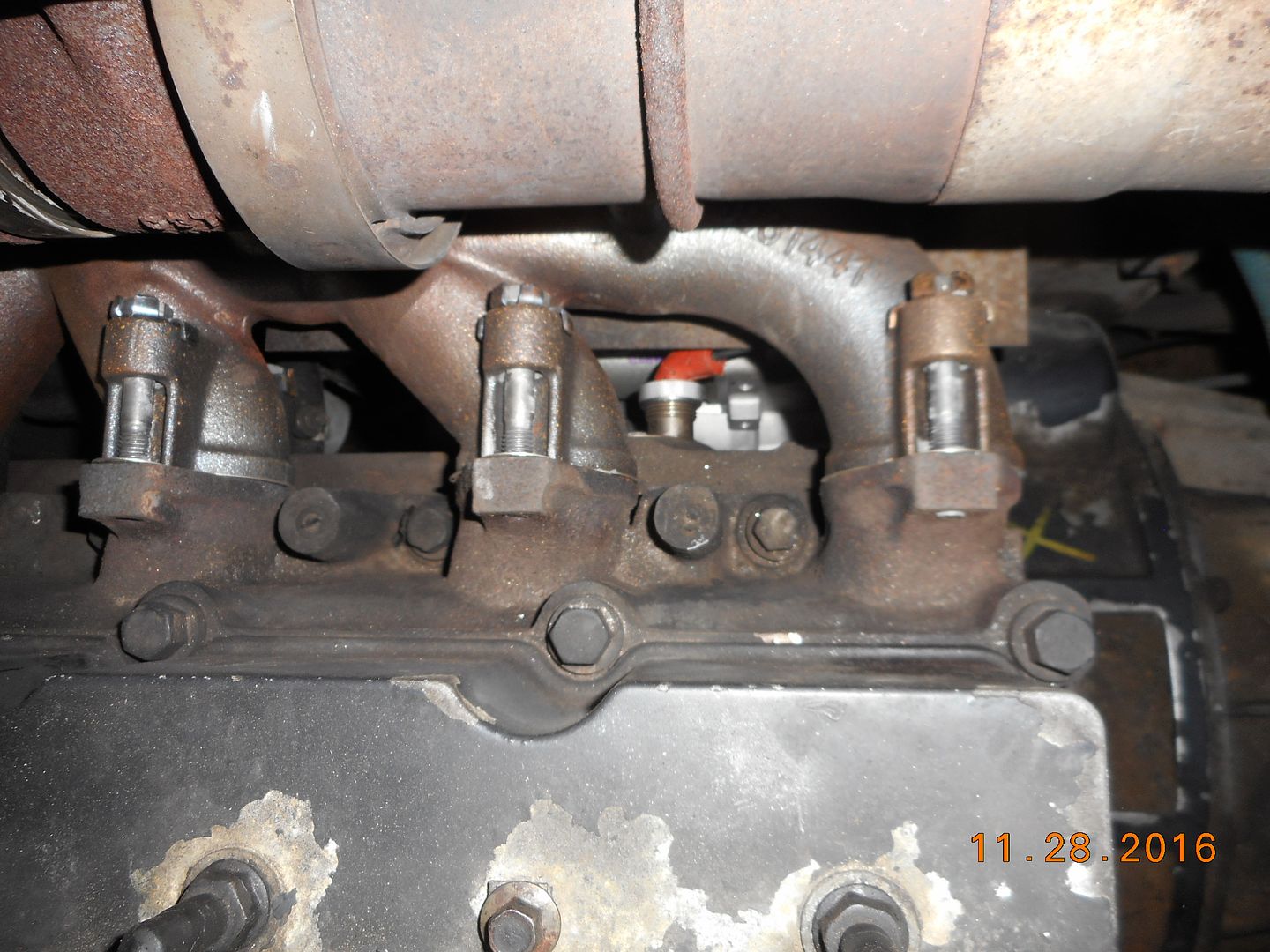

When I got the Monarch I began an inspection of the systems to evaluate their functions and familiarize myself to where things are, etc. I was pleased to find that overall Tom took good care of the coach and for a 20 year old coach it is quite good. I replaced the rear tires due to age. Inspection of the records and the engine revealed broken bolts on the exhaust manifold. The front bolt was obviously gone. Closer inspection revealed 3 others had broken off. The two ports on the front of the engine were leaking exhaust. This became a priority fix. With winter coming on I was concerned about water in the air lines freezing and disabling brake and suspension. Tom only ran in warm weather and no records I had showed the air dryer had been serviced. Second priority. Meanwhile, the engine block heater had failed. (Once again, I'm not sure Tom ever used it in the warm temps) It is located directly beneath the manifold. Also, the valves were due for adjustment. Last observation. The engine seemed to crank slower than I thought it should, despite good batteries and cable connections. Since diesel starting is so sensitive to cranking speed I wanted all I can get. 20 years ago I might have done all these things. Site members know I am no lightweight on projects, but the manifold bolts looked like a job for a masochistic contortionist. I was afraid more bolts would break when removed. I was correct. Sooo, time to find a good Cummins shop. There are 4 or 5 diesel shops within 50 miles. I ended up in Gaylord at the Michigan Kenworth repair shop. They were recommended by locals and the service has been run by the same brothers for 25 years. We both agreed the manifold bolts were a nightmare. I mentioned all my concerns and gave them the keys. Since they were crazy busy and I wasn't in a big hurry it took about 2 weeks. In the end, 5 more exhaust manifold bolts broke off during removal. The exhaust manifold was too warped to reuse. It took about 20 hours to remove the turbo, manifold, etc, drill out 9 bolts, cut off turbo bolts, remount turbo on new manifold and reinstall. The shop gave me a break and billed it for 16 hours (2 days!) and I was not surprised. Manifold bolts are metric, hardened and about $12 each. The gaskets are $11 per hole and the bolt retainer plates are $3 per hole, so $38 bucks times 6 holes… the manifold was actually reasonable at at bit over $400. Turbo mounting studs, gaskets and air tube and exhaust clamps bring parts to about $1000.    So, this became an investment. The rest was not so bad. The engine block heater is directly below the manifold and easy to change with manifold out, about $200. (You can see the red connector, starter below that)  Starter was indeed cranking slow. It is also way easier to replace with manifold out so I gave them the green light for a new starter, about $450 more. Spins noticably faster.  Finally, they drained all air lines, etc and replaced the air dryer cartridge, another $200. Adjusted valves also. In spite of the bill I am very happy with the service I got from the shop. Good communication and open pricing. No surprises. Manifold heating and cooling seems to cause the manifold to shrink over time, bending the bolts as it moves around. Between hot/cold cycling and corrosion the bolts are the weak link it seems. Something to keep an eye on in the future. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | ||

|

8/19 8/19 |

Good write up. I am sure you will get your money back in enjoyment and peace of mind. CHEERS | |||

|

8/11 8/11 |

Good Write-Up Steve, I am not sure about the service managers theory about the bolt issue being caused or exacerbated by lack of use. Helen and I average 10,000 or more miles per year and those damned bolts didn't seem to care. I consider myself to be a master of removing broken exhaust manifold studs/bolts and after barely scratching them with my high-dollar drill bits I decided it was too easy to eject the cylinder head so voila, less than one hour later. the head was in the bed of Helen's truck and off to machine shop where they had to be milled out. Upon reassembly, besides the Nevr-Seize, I sprayed everything with 2,000 degree engine exhaust paint. I keep the engine bay pressure washed and paint it up when needed, the parts I can actually see that is. Billy & Helen Thibodeaux Retired from Billy Thibodeaux's Premiere RV, Inc. Scott, LA 70583 I-10 Exit 97 The Farm is near Duson, LA I-10 Exit 92 then N 1 mile on right Three Full 50 Amp RV Hookups ! billynhelen@me.com Data Tag: 9404-3908-36XI-2C 1994 Sovereign 36' Widebody on Spartan IC (Mountain Master Lite) Chassis. Powered by Cummins ISL9-450 Onan 8,000 Quiet Diesel Genset Toad: 2018 Chevy Colorado ZR2 Diesel with M&G Car Brake  | |||

|

Official Barth Junkie |

After more inspection of the manifold and the bolts I am inclined to think it is not necessarily corrosion, as you are suggesting. I am thinking that due to the length of the manifold, when it heats and cools it gets longer and shorter each cycle. I noticed that the holes in the manifold bosses are well oversize and there is a large gap between the cylinder head and the bolt head, apparently to allow lateral squirm as the manifold heat cycles. The net effect is to rock the bolts fore and aft each time the manifold heats and cools. Perhaps this is causing the bolts to crack at the head surface? It would be interesting to compare bolt life with the 2 or 3 piece manifolds. They should not be moving around as much... 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

I certainly agree with you Steve, and I have proof of this failure! I am putting on my 4th exhaust manifold in 260K miles. First one was the original and was cracked around the turbo flange, 70K mills. I had noticed that in addition top the cracks, the manifold was definitely shorter as compared to the new one. In fact when removing the bolts, #1 and #6 bolts were hard to remove as they were in contact with the edge of the mounting holes. Second one did not crack but after about 100K more mills (170K total) I could see the this manifold had also shortened up. The end bolts again(#1, #6) were at the edges of the mounting holes and visually it could be seen that the bolts were not centered in the troughs. I talked with Cummins and they said they now had a manifold that was made in Brazil and was of a different material base. Removed number 2 and tried the "new design". As always when replacing the manifolds, I replaced the bolts, #3 was on, also I would re-torque the bolts after 100 miles when the engine was hot. Interestingly enough, this new manifold did not seem to shrink as much but indeed even the new material design was getting shorter. When starting my major redo last month, I noticed I had a broken bolt top side of #6 exhaust! sure enough, when measuring ths manifold and comparing to the previous (#2) it had shrunk about the same. #1 bolts were tight against the holes and channels. 260K miles. Made up a drilling jig, used a carbide straight flute drill and was able to get the remains of the broken bolt out. These are 10.9 class bolts and are hard, but also there was a lot of work hardening at the fracture area. I am now going with an after market 2 piece manifold. I would have prefered a 3 piece but my turbo is mounted below the manifold between #4, #5, only 2 piece would work. New manifold is really a good design, better flow, smoother transitions, threaded bungs for EGT sensors. My turbo checked out OK so I should be good to go. Will be interesting to see how the two piece manifold works. I work this 5.9L very hard, not surprised about some of my issues. I can not leave my area without going up mountains, not hills, mountains. Not unusual for me to run 15-30 minutes at max EGT. My total rolling weight Barth and trailer is about 25K Lbs. More later Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

3/11 3/11 |

I recently rebuilt a Ford 6.4 diesel and after much investigation I discarded the head and exhaust bolts and installed an ARP stud set. They make complete kits for ALL diesels that forever ends the broken bolt issue. The studs use 190,000psi tensile strength alloy steel(see ARP website) and your maintenance will involve only hex nuts. Their kits are especially designed for the many engines that have undersized bolts. The complete head kit ran $550. 1993 32' Regency Wide Body, 4 speed Allison Trans, Front Entry door, Diamond Plate aluminum roof & 1981 Euro 22' w Chevy 350 engine and TH 400 tranny | |||

|

8/11 8/11 |

Ed, Whose manifold did you end up using and how much did it cost? Does it use a simple slip-fit that expands when warm to seal off or is there a sealing ring(s) involved? Billy T Billy & Helen Thibodeaux Retired from Billy Thibodeaux's Premiere RV, Inc. Scott, LA 70583 I-10 Exit 97 The Farm is near Duson, LA I-10 Exit 92 then N 1 mile on right Three Full 50 Amp RV Hookups ! billynhelen@me.com Data Tag: 9404-3908-36XI-2C 1994 Sovereign 36' Widebody on Spartan IC (Mountain Master Lite) Chassis. Powered by Cummins ISL9-450 Onan 8,000 Quiet Diesel Genset Toad: 2018 Chevy Colorado ZR2 Diesel with M&G Car Brake  | |||

|

I got the manifold from Diesel Power Products, LINK It is designed for early Cummins industrial and RV applications. It was $400.00, 12 bolts, 6 gaskets, turbo gasket and free shipping. Wasn't crazy about the bolts, 8.8 class allen head. I replaced with flange head 10.9 class bolts The expansion joint is a light press fit probably 1.5 inch long, don't believe there are any sealing rings. I have used 3 piece manifolds on 8.3 industrial equipment engines before and had no problem with leakage or cracking. Because the 5.9L application has the turbo mounted below the manifold and is between cylinder 4 and 5, that could only be a 2 piece design. Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

8/11 8/11 |

Gotcha Billy & Helen Thibodeaux Retired from Billy Thibodeaux's Premiere RV, Inc. Scott, LA 70583 I-10 Exit 97 The Farm is near Duson, LA I-10 Exit 92 then N 1 mile on right Three Full 50 Amp RV Hookups ! billynhelen@me.com Data Tag: 9404-3908-36XI-2C 1994 Sovereign 36' Widebody on Spartan IC (Mountain Master Lite) Chassis. Powered by Cummins ISL9-450 Onan 8,000 Quiet Diesel Genset Toad: 2018 Chevy Colorado ZR2 Diesel with M&G Car Brake  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.