Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

6/12 6/12Formally known as "Humbojb"  |

We were up in the Great Smoky Mountain National Park this week and one day, in the parking lot of a mountain golf course, the Barth decided it was not going to start. The problem was quickly traced to no juice to the starter. Fortunately, we were there to play golf, so we did and afterward when the Barth was cooled off, Tere went under there and found the defective wire, and did a temporary fix to get us back to the campground. Nothing wrong with the solenoid or the starter, but that thing is in an impossible location. Anything wrong with relocating the solenoid to a place where it would be easier to get to? My son-in-law has the starter solenoid on his '69 Camaro done this way. BTW, am I a lucky guy or not? I've got a wife who is willing to crawl underneath a Barth on a hot and humid day and fix it. Her Daddy brought her up well. I might have been able to do it but would have probably been in bed for a week. Jim

| |||||||||||

|

Official Barth Junkie |

I think I'm in love with your wife! The stock GM starter uses the solenoid to engage the gear into the flywheel. I don't think it can be bypassed. The location is indeed a PITA. Some of the aftermarket starters have permanent magnets and remote solenoids, maybe someone has used one? 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

I had all sorts of fits with my starter before I got it sorted out....15 starters later...yes, 15 starters later....look at some of my posts on 454 starters...sae, metric, rebuilt, reman,shimmed, non-shimmed, gear-reduction race starters, 9 tooth, 16 tooth, combo 9 & 16 tooth... When you talk about the wire, do you mean the starter cable or the wire that brings power to the ignition or what? I did a remote setup and the only wire I have going is to the starter itself....worked out well....also wrapped in a blanket to cut down heat...I do have headers also... One other thing I did, was there is a fusible link that was across from the front-right corner (near the fuel pump) of mine that would blow. I relocated it to by the distributor and put a fuse there...sure beat crawling up around the right front tire along the frame rail on a hot engine... P.S. Could I send my wife over for lessons from Tere? | ||||

|

| First Month Member |

Nope. It can't.

I use a permanent magnet starter on three of my big block chevies. The type of starter makes no difference if there is no power. Both PM and traditional chevy starters require a solenoid on top of them. When speaking of solenoids, we need to define our terms, as per Voltaire: A solenoid is a device for converting electrical energy into (usually) linear mechanical energy. It does this by means of a coil becoming an electromanet, forcing a slug to move in or out. This can let air into your air horns, oil into your HWH jacks, release flap brakes on a Cessna 205, or pull the starter gear into engagement with the flywheel teeth......This last purpose is what the solenoid on top of the Chevy starter does. A relay is a device that also has a coil that forces a slug (or metal bar) to move, but there is a set of contacts built into it. It typical use is to use a small amount of electricity to connect two big wires so a large amount of electricity can go from one to the other. This also occurs in the Chevy starter solenoid. The slug both engages the gears and makes the contact for heavy current to flow into the starter. This is where people start mis-naming things. Technically, the Chevy solenoid is a solenoid/relay, but no one outside of a classroom calls it that. Now, it gets even worse. A large relay in the starting circuit (but not on the starter) is very often called a solenoid, even though it does nothing mechanical. This is often called a remote starter solenoid. Or a "magnetic switch". This is often used to take the load off of the P30 starter switch and wiring, allowing more current to go to the coil of the solenoid on the starter. There is a GM bulletin on this. It is usually on a tubular support on the right upper side of the doghouse area. PM me if you would like a copy. I use one on my boat because the wire run from battery to start switch and back to the starter is pretty long, and can have a voltage drop if no heavy enough. So, to wrap it up, there are two things called a solenoid. The one on top of the starter is part of the starter and needs to be there to pull the gear into position. It is subject to heat problems. There are high temp solenoids out there. Heat shields work, too. Having a Belleville washer under the nut on the small terminal keeps the connection tight when the terminal screw expands with heat. There is a Chevy bulletin on this. PM me. Holler if not clear. No coffee yet. . 84 30T PeeThirty-Something, 502 powered | |||

|

Official Barth Junkie |

I must have been thinking about Fords... some of them used to have a side lever arm that engaged the gears and then made contact. The lever was covered by a sheet metal shroud. They had one connection and a "solenoid" relay on the inside fender near the battery. (I thought maybe some might use a centrifugal clutch type drive, etc to avoid the need for solenoid action.) I have the high temp solenoid, heat shield, and Belleville washer. Not sure if it helps but I have Thorley headers, too. Never had any trouble. The "Aux start" relay had an additional heavy wire to the solenoid. Too many huge wires. Since I never seem to need the Aux start function, I removed that wire. Still a PITA to get it in and connections snug. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| First Month Member |

Yup. That's essentially what the GM SB is. I use a Ford relay on my boat to avoid long heavy start switch wires.

The old Bendix system worked pretty well if kept clean and lubed. Some gensets use it.

Thorleys have less mass to contribute heat to the post-shutdown heat soak. However, they need a little shielding to keep heat from frying the wires near the starter. Thermo Tech sleeves work well. Or just wrap HD alum foil around the wires, taking care not to induce a short. Small sheet metal heat shields can be attached to the headers if spacer tabs are used. Drawing on request. . 84 30T PeeThirty-Something, 502 powered | |||

|

6/12 6/12Formally known as "Humbojb"  |

Slight Thread Drift RE: Thorley Headers

Things we learned while looking up other things. FYI COPIED FROM THORLEY WARRANTY: "2)The use of any type of “header wrapping” voids the warranty. Using any sort of wrapping material on the headers destroys the tubing’s ability to dissipate heat, causing very rapid deterioration of the metal and the subsequent failure of the headers" Tere

| ||||||||||||

|

| First Month Member |

To clarify.................When I wrote "wrap HD alum foil around them", I meant wrap the foil around the wiring, not the headers. I will edit my post to make it more clear. Thanks for pointing that out. Any heat shielding of the headers themselves should be done with sheet metal with standoff tabs. Drawing on request. . 84 30T PeeThirty-Something, 502 powered | |||

|

6/12 6/12Formally known as "Humbojb"  |

would like to have the drawings bill. We got a templet for a heat shield but it was for stock headers not thorley headers. Would like to make some shields for our thorleys. Also, where would one get a belleville washer? Jim

| ||||||||||||

|

6/12 6/12Formally known as "Humbojb"  |

billh I was only giving info for those who might be "thinking" of wrapping anything. First thing check warranty or call manufacturer before moving forward. Like I didn't do. Yes I confess... I wrapped my Thorley headers & found out after seeing the damage I'd better check my warranty. Damage noticeable but removed them before they got too bad. You were clear to me. Thanks, Tere

| ||||||||||||

|

| First Month Member |

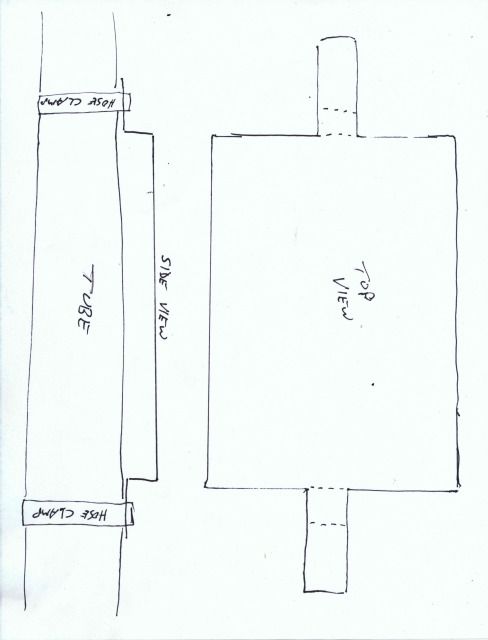

You could buy some Thermo Tec 11630 Clamp On Exhaust Heat Shields, but they are a little pricey. You could make a copy of them of sheet metal, but cutting the slots for the clamps can be a pain. If you dispense with the center clamp you can cut slots in from each end and it will work pretty well. Be sure your slots end at a drilled hole. This will delay cracking at that point. Or you could cut something like this:  out of flat flashing metal from Lowes. A tin can works, but doesn't last as long. The skinny tab at each end is bent 90 deg down, then 90 deg out to space the large part up from the pipe a little. The tab is held to the pipe with a hose clamp. These can be whatever width or length you like, depending on location. You can curve it to fit around the pipe. The inside corner where the tab meets the body should be a nice radius, either because you drilled a hole first or with a rat tail file. You can also cut them on a curve if location dictates. Lining them with one layer of Thermo Tec's flat fiberglass/foil material makes them even better. Pop rivets hold it well if you use a backing washer.

A good 5 cent question deserves a 5 dollar answer Starter solenoids are notoriously heat-sensitive on Chevys. I have found the Bakelite cap on solenoids already cracked, ready to fall apart if you looked at it wrong. Replace the solenoid with the high heat one, GM 1114458, or 10457024. . It includes a shorter return spring, pn 1978281, or 1958679. The small terminal on the solenoid should have a Belleville washer/nut to keep the small connection tight. The start terminal is long and grows when it gets hot, loosening the connection. When it cools down, the stud becomes shorter, and a good connection is restored. The nut/Belleville washer is Delco 2030900 and flat washer 131015. Torque to 12 to 17 in lbs.. A Belleville washer is better than a split lock washer because it provides 360 degree pressure rather than in just one spot. If you can’t get the GM Belleville nut/washer, use a toothed lock washer. That stud growing is why Chevvies are notorious for not starting when hot, but OK when cooler. A heat shield is a good idea, too. GM sells a heat shield for the solenoid, pn 10068600, but I prefer one that also shields the starter as well. After I have it installed and the wiring routed, I add a little more Thermo Tech shielding around the solenoid with their tape to hold it in place, and foil or foil/fiberglass protection around the wires, as well . Install a good ground cable to a starter mounting bolt. I like to run a cable from a starter mount bolt to the same bolt where the frame is grounded to the battery. . 84 30T PeeThirty-Something, 502 powered | |||

|

6/12 6/12Formally known as "Humbojb"  |

My choices from fastenal for the belleville washer are stainless steel, steel or spring steel, or something called acetal. There are no grades noted on the metal for coomparison. I don't have the standard starter so I don't know what the size of the OEM starter post is. Mine is a #10 post. While I'm waiting for a response from our experts I will look up the GM part 2030900 referenced on earlier post for size & grade of metal. Thanks for all this input. Tere

| ||||||||||||

|

| First Month Member |

Spring steel will be fine

10 is fine.

Any luck on that? I gave it a quick Google with no source found. A GM dealer might still have it. I haven't bought one in a while. . 84 30T PeeThirty-Something, 502 powered | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.