Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

3/23 3/23 |

Well; I pulled the flapper valve out, in the process I broke 2 of 3 studs, so it was frozen but in a mostly open state. Maybe a 10% reduction in flow at the most. So got to drill out some studs or find a sexy gadget to externally replace the broken studs. Found a gasket that should work to seal the system with out the valve. | |||

|

1/18 1/18 |

Duane , The regulator is in the supply line . Bob Year:: 1986 Model:: Barth Regal Length:: 25 ft Engine:: New Chevy 454 HO Chassis:: P-30 Data Tag Number:: 8606 3339 25FP2 | |||

|

3/23 3/23 |

Thanks Bob Because I get good flow from the engine mounted fuel pump when the system is cool, and I have exhausted, most stuff, except converting to a TBI system ( I would really like to do this but it is about $2000). I also have convinced myself that it is vapor lock causing my problem. It is so hot under the hatch and I can not find a way to cool it down adequately. Your solution of the inline auxiliary fuel pump and regulator will increase the inline pressure, I hope enough to stop fuel boiling. I also will put in a lower temperature thermostat and a carburetor insulator. I am not sure it will help if the boiling is happening in the carburetor bowl. I sure thank all who have given me help with this problem, will let you know if it works, hope to make the GTG in October!!! | |||

|

1/18 1/18 |

Duane , Go to the search section on barthmobile.com & put in vapor lock . There is many articles on it & good reading . Sounds like it might be your problem . Hope it helps , Bob Year:: 1986 Model:: Barth Regal Length:: 25 ft Engine:: New Chevy 454 HO Chassis:: P-30 Data Tag Number:: 8606 3339 25FP2 | |||

|

3/23 3/23 |

Bob, I read all the vapor lock information you suggested , seems like a common problem. I think there must be a spot in the fuel system that gets hot enough to boil fuel after my unit runs for an hour or so. If the engine is not cooled completely it happens faster. So your advise on the electric fuel pump is the most probable repair so far. I was removing the cold engine carb heat valve and I noticed there is a heat shield around the manifold on that side, close to the fuel lines, it has deteriorated a bit, and might be the hot spot. I bet headers would be of help there. Thanks Duane | |||

|

3/23 3/23 |

Steve, on that flapper valve, even if there is just a bit of back pressure differential, would the heat from on side of the engine exhaust cross to the other, heating the manifold. Have you ever hear of anyone plugging the inlet on one side or the other to totally stop any cross over? | |||

|

Official Barth Junkie |

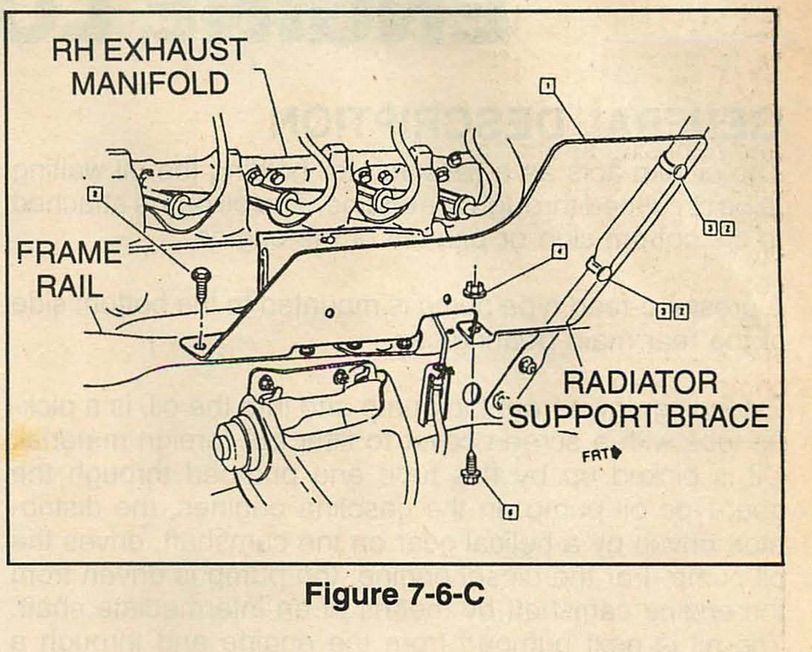

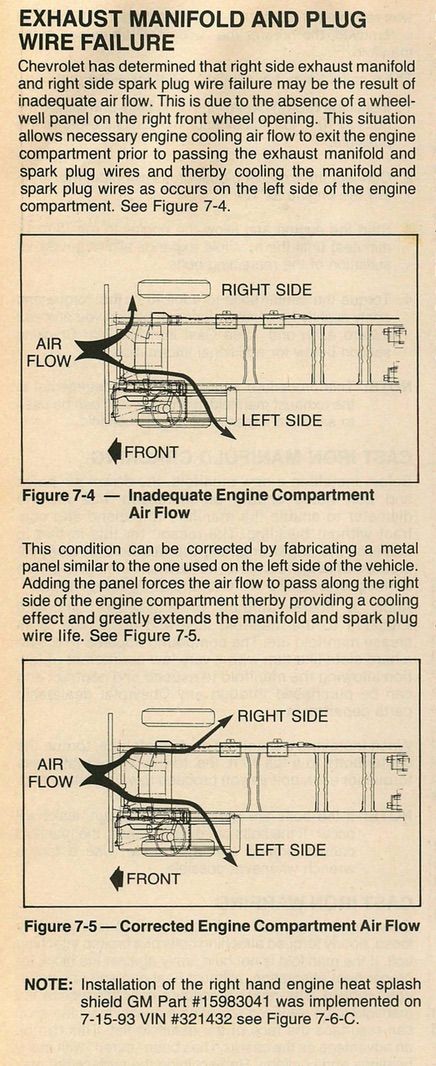

The hot rod guys dont want heated induction air (less density) they do block them off. If you have headers they usually cover the riser ports. Considering the heat in a motorhome doghouse, there is no need for them. In extreme cold, the warmed manifolds do minimize the amount of liquid fuel washing the cylinder walls during warmup but most coach users are not running in that kind of cold. Vapor lock results in fuel starvation. Several factors: just like a radiator or a pressure cooker, the higher the pressure the higher the boiling point. This is the primary advantage of the rear pump. Changes most of the line from a suction line to a pressurized line. GM started with sucking on a 20 ft line to the tank, to rear mounted pusher pumps, to tank mounted pumps with no suction lines at all. Learning curve at owner's expense. Another factor: lag time. If the fuel sits in a hot place for very long, it gets hot too. If the fuel keeps flowing all the time (ie recirculating system) it never stays in the hot area long enough to boil. So GM went from a dead-ended system feeding the carb through the engine's mechanical pump, to the frame booster pump feeding an engine pump, to an engine pump with a bypass port to allow recirculation back to the tank. Final version had in tank pumps with recirculation via the TBI unit. Another learning curve. In later versions, GM installed air dams on the right side of the engine to channel more air over the engine. See if you have an air dam, right side. Do a site search for more info:   I removed the in tank pumps and filters, plumbed directly to canister primary filters. (3/8 hose) From there to the 6 port tank selector valve, to the inline electric fuel pump. 1/2 inch steel fuel line running forward, secondary filter on frame rail. Tees near engine, one side SS braided flex hose to the throttle body, the other a pressure gauge. 3/8 SS braided from the throttle body then 3/8 steel return line back to the tank selector valve. With a carb you would be running 4-6 psi pump with the GM TBI it is 11-13 psi. Later injection systems used much higher pressures. Recirculating systems work the best. My biggest problems were on the suction side. In tank sock filters got plugged, in tank pumps failed. Large external filters would be my #1 choice. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Captain Doom |

Although mine's a diesel, I had fuel-flow issues. I finally removed the in-tank sock and stupidly replaced it with an inline 5µ filter. While it didn't plug up, the restriction to flow was too much for the suction side of the lift (fuel) pump to overcome. I finally replaced it with an Holley inline 100µ filter from Summit Racing. It's not cheap, but it's accessible, and I can backflush it in 5 minutes. Best of all, it works well. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

3/23 3/23 |

Hey all and Steve, I removed the passenger side manifold (no headers) all I see are 4 rectangular holes for the exhaust ports. Of course I can't plug them, where does it feed across, I am thinking I will have to pull the intake manifold to find the passage. Broke more studs, sick of drilling them out. NAPA had a self regulating electric inline fuel pump, 6-8 psi. I also got a new fuel filter, not as fancy as Steve's but with a replaceable cartridge. Is the template for the heat shield for passenger side air flow still on the site, may as well do that too. Thanks Duane | |||

|

3/23 3/23 |

BTW my engine mechanical fuel pump does have a return, hence the use a 6 way selector valve. I plan on installing the new electric fuel pump and filters after this valve. | |||

|

Captain Doom |

I should have mentioned, the Holley inline filter is to protect the lift pump; there is another large fuel filter on the engine. Rusty '94 28' Breakaway: MilSpec AMG 6.5L TD 230HP Nelson and Chester, not-spoiled Golden Retrievers Sometimes I think we're alone in the universe, and sometimes I think we're not. In either case the idea is quite staggering. - Arthur C. Clarke It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.