Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

3/23 3/23 |

OK,, I have had a leak in my radiator since I bought the Euro. It was not to bad so, although I have gotten a replacement radiator it also leaked and could not be repaired unless a new core was installed, about $1000. So I found a single pass aluminum radiator a bit smaller in size and lacking a transmission cooling coil. I thought I would add an air cooled transmission cooler. What do you think about a single pass vrs the original that I think is a dual pass, Plus mine has the coolant running up and down vrs left to right.. I am removing the radiator, what a mess!! 1971 24 ft Barth Continental P30 chassis 350 engine | ||

|

Official Barth Junkie |

I am in favor of isolating the trans cooler in any case. Makes replacing the radiator easier and avoids combining transmission heat with engine heat in the same radiator. Under heavy loads you can see trans temps up to 250-300 degrees. That heat has to be shed by the same rad that cools a 200 degree engine. A good sized trans cooler will keep trans happy and reduce engine overheating. I installed 2 of them on the Regal. Also might consider an extra electric fan on the main rad. I put those on my Regal also. Great for stop and go traffic or long hills.  I don't think the crossflow is a problem, most of the non Euro coaches have them. As for single vs double, good question... Depending on the core design it could be better or worse. It is a balance between how much water flows, how much surface area to transfer the heat and how much airflow over those surfaces. What was the original application for your replacement? If it was for a big block V8 application you should be fine. One thing for sure, the aluminum rad is a LOT lighter! Good luck, Duane 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Thanks Steve, the rad I am using or will use, is from a hot rod radiator maker, the Technician told me this design is used for hot rods with a big block. This one can be used for cross flow or up flow. BTW The fittings are not welded on this unit so I locate them right where I want them, I am not a welder so more expense to get them welded on and the holes opened, I can do the holes I think, on my drill press. The transmission cooler will fit below the rad in the space left over, because this rad is 4 inches shorter than the old one. 31 vrs 35 approx. I had already installed 2 electric cooling fans so I hope that helps too. I really wish the one I got from you was repairable. While I have this rad out I was thinking a new water pump, I wonder if they make a high flow version. I might as well replace the fan clutch. I would like to change the v-belt for the water pump and alternator to a flat grooved belt but I would need all new pulleys and a belt tensioner device. This blasted thing has me in the POOR house already. I started this job because the leak got worse on my trip home from Snotan, and I found a replacement rad in a salvage yard, however close inspection revealed it was a POJ so no go. Work goes on have not got the old rad out yet. Geez looking at the picture from your Regal, you have a lot of room to work, the Glassnose does not come off and it is tearing up my arms and hands working between the Rad and nose frame...Yuk!!! Bolts are impossible to reach without getting cut.. 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

I think this was the high volume pump I used: Summit $73 plus shipping https://www.summitracing.com/p...e/7-4l-454/model/p30 Fan clutch would be smart too. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Well it is out!! I am going to lose about 20% of the cooling area going to this radiator, but I am relocating the transmission cooling. cooling core is 25.75 x 18 vrs 29.5 X 19.5. I guess I will not know how it works until a good hot day and Benebob behind the wheel! Performance water pump (Thanks Steve) and extra electric cooling fans ought to help also. The single pass vrs the dual pass has yet to be determined too. New radiator supposed to be here Monday. 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

3/23 3/23 |

Steve or whoever, I seem to have a full length A/C condenser and what I believe to be an oil cooler ( have not traced it) in front of the Rad. Did you have the same? I am removing the condenser for now anyway, the chassis A/C does not do much cooling even at its best I guess. So in front of the rad I will have the oil cooler and transmission cooler, putting a second transmission cooler a bit smaller below the rad. Will these two items, hurt the air flow or cooling very much? The removal of the condenser even though it has not been used in years, should help air flow I think, real close together fins and some were plugged with mud. The new rad arrived yesterday way ahead of promise, only disappointment was it was made in China. New water pump and fan clutch due Monday. 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

I think losing the AC condensor will improve air flow and cooling nicely. The other coolers should help too. Try to leave space for air flow, it should be fine. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

If the rain would stop I could finish this job. I have the new rad in place, new water pump and fan clutch all in. I need to locate the transmission coolers and run the hoses. Finish the radiator hose set up, it is a bit different than the stock set up I took out, I changed some of the radiator hose connection points. A couple of hours more I guess, when the rain quits..hope it cools better than the old one. SteveVW I see you put your transmission coolers in parallel I am curious why, I was going to do a series set up. 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

It was a while back when I did that, not sure what I was smoking then but I decided that going parallel would split the flow for less restriction. (I was interested in slowing the flow through the coolers...). Restriction in the cooler circuit also leads to higher back pressure in the torque convertor, which leads to more crankshaft thrust force and bearing wear. The efficiency of a heat transfer device like a radiator depends on several factors: surface area, flow of liquid inside, flow of air outside, conductivity of the radiator core tubes and the difference in temperature from the hot side to the cold side, among others. In theory, if both coolers split the hot incoming oil it seemed that they would have the highest difference in temp to the air, promoting maximum heat transfer. In series, the second cooler would get precooled oil and have less heat to shed compared to the first one. Since each cooler now has 1/2 the total volume of oil flow to cool, the flow rate is 1/2, meaning twice the time spent flowing through the cooler. More time to cool before returning to the trans... Honestly, I'm not sure this is that important, might make very little difference parallel and series. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Parallel is a good idea so long as the pressure drops are equal and in this instance they probably will be. If some obstruction occurs the flow obviously will favor the path of least resistance. Flip a coin and periodically check the exit temps. | |||

|

3/23 3/23 |

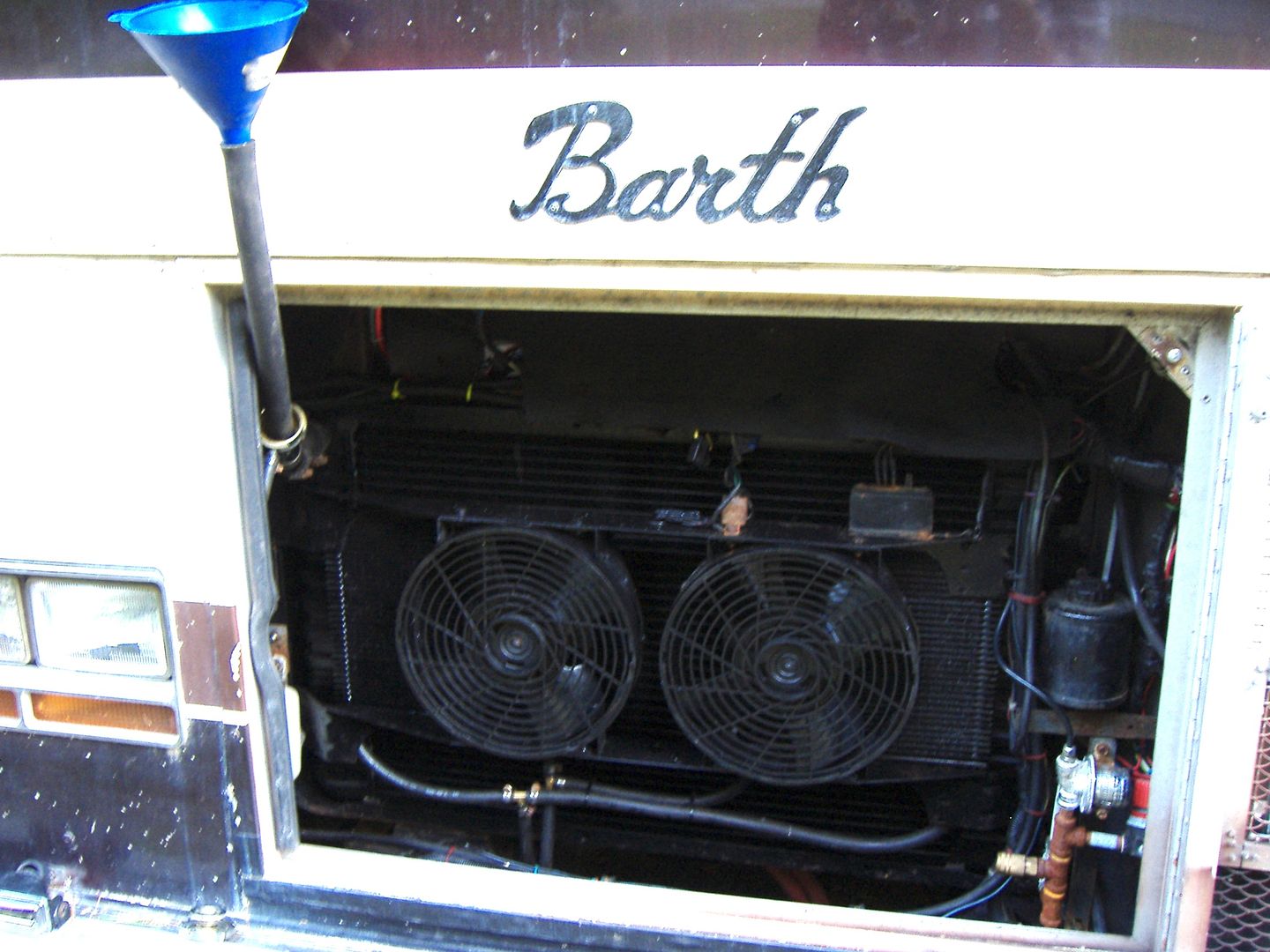

My transmission coolers are not the same size so I put them in series...give it a shot!! The good news is I finished the job and did a test run, big smile! The coolant out temperature is less than 80C and the ambient is 85F at about 55mph. before this change it would easily be 110C. I am going to have to put a thermostat back in the engine.. Another change, most of the cars I have had with a temp gauge would run cooler on the road and when I got back to traffic they would get hotter for a bit, this RV always got cooler when I got slowed or stopped. When I got in my drive way today it warmed up maybe 5C as I was making the turns and backing in. Bye the way I was not even using the electric fans!!!! I was thinking a big help was replacing the fan clutch and the heavy duty water pump. I bet my fan is spinning a lot faster at highway speeds. Probably the original clutch it was a replacement water pump. So if anyone else has radiator leaks and is not afraid to change to aluminum here is the link. I spent less than half of getting a repaired radiator. All though it was a bit of challenge making the changes to get a good fit. https://www.speedwaymotors.com...x-19-Inch,93701.html On the road again!! Me and Willie!!! No Pot though just alcohol..lol 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

Sounds like it worked out really well! How about a couple cool photos? (What do you have have to do around here to get pictures, pull down your pants? Oh, wait a minute, I did that...) I'm impressed with your tabla rasa approach, build from basic parts, adjust to fit, get it the way you want it. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Photo bucket and I have this serious hate going on right now, if it ever subsides A picture I will post lol 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

Just email them to Kevin, I'm sure he has nothing better to do than fool with the Photobucket demons. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Kevin and I have spent numerous hours with the PB demons, I think it is my brain that needs the adjustment. 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.