Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

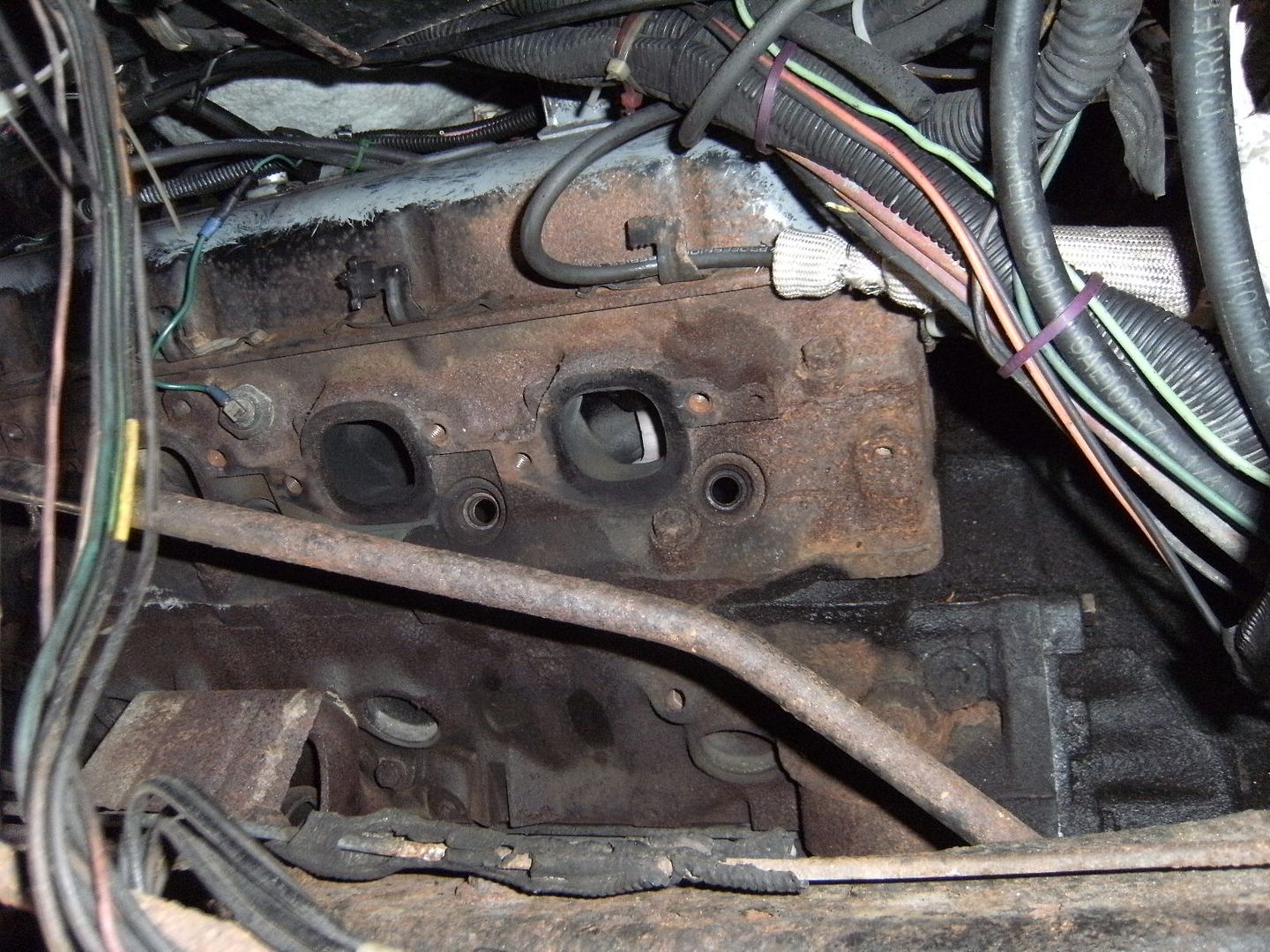

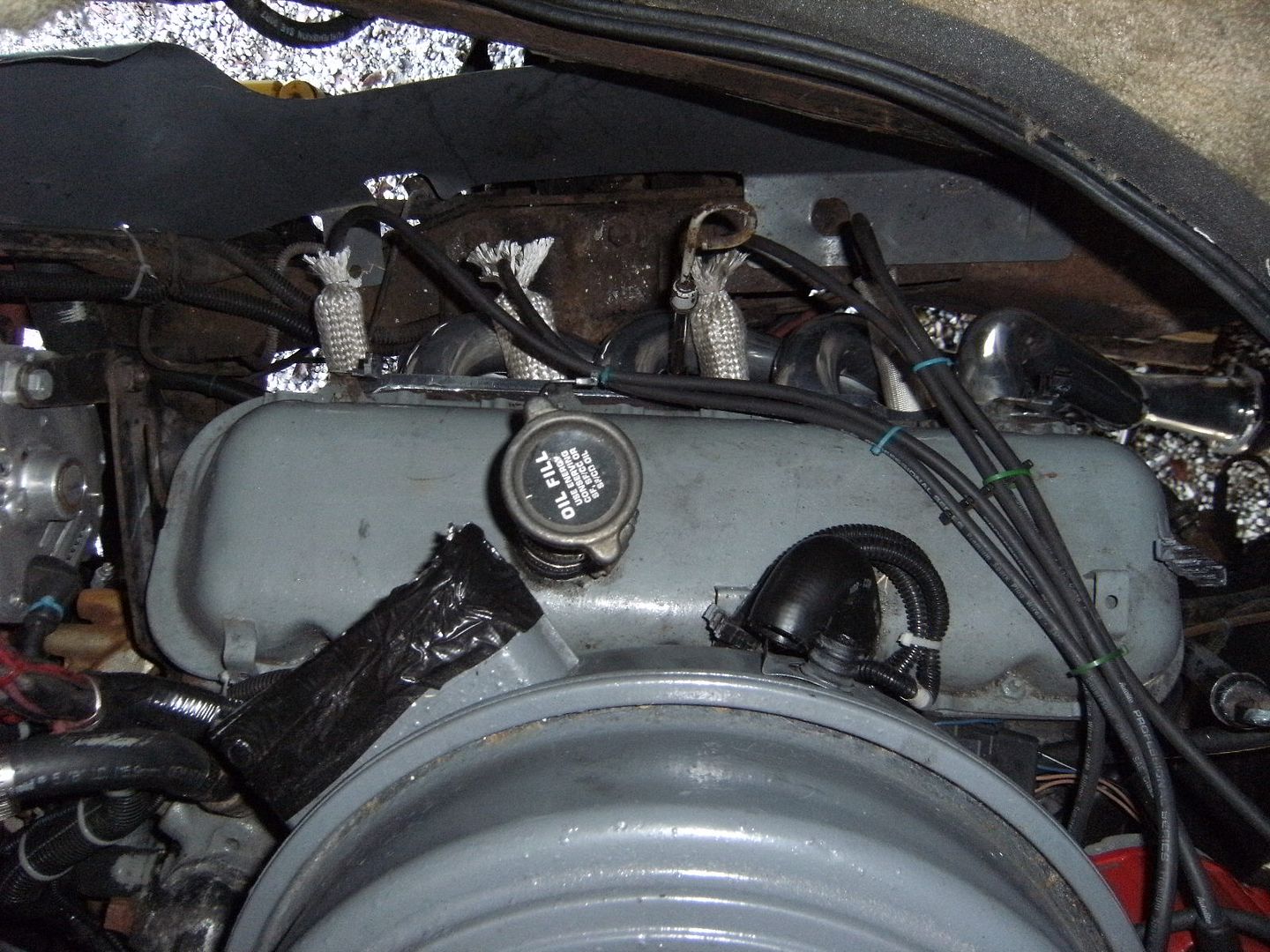

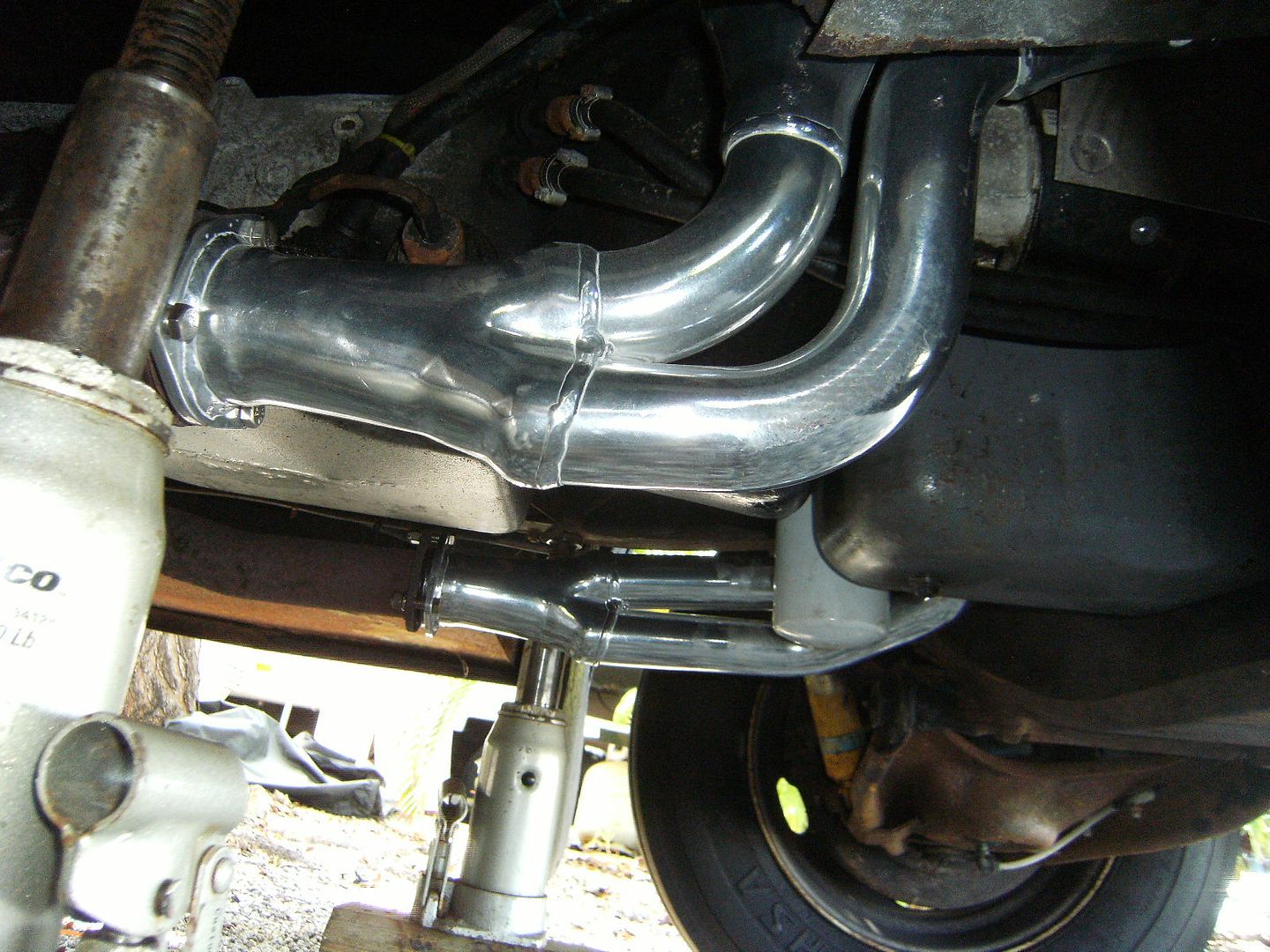

On the way home from Hillsborough in Dec it got louder. Found a cracked weld in the left header. Did the old soup can patch and drove back to Michigan. I purchased a new set of headers and was planning to install at least the left side before returning to Florida, whenever we had a thaw... Well a couple more hose clamps later we made it to Sunshine Key Barth Spa and rehab center. I took the left side out today. Access to the 2 rear spark plugs and the rear manifold bolts is easy through the wheel well. 3 bolts hold the exhaust flange to the pipe.  From above, I took out the other 2 plugs and the other 5 manifold bolts. It was fairly easy to snake the header out. I have the tall style filter, if you remove the filter it would be slightly easier.  The new headers are ceramic coated, old ones were aluminized. The old set had the stumps for the AIR smog pump pipes, long disconnected but from the looks, somewhat obstructive.  The crack in the old set got quite a bit bigger!  The new one went straight in, easier than the old without the smog pump stumps in the way. I'll have final pics for the install later... it started raining here. First rain since we got here. I will do the right side and replace the starter next. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | ||

|

3/19 3/19 |

Good presentation, Steve. That ole header sure blew out! new design looks like much better flow -- will get you closer to that 250hp you're seeking | |||

|

3/22 3/22 |

What no snow? I am going to try and move DBarth tomorrow so it doesn't sink when it actually starts to thaw. Moved snow all day toward that end. Plug in the engine heater in the am and see what happens when I get home from work. it started raining here. First rain since we got here. Rain how I'd like to see rain. Oh wait we are supposed to have freezing rain "AGGGGG" Dana & Lynn 1997 38ft Monarch front entry Spartan Mountain Master Chassis Cummins 8.3 325hp Allison MD-3060 6 speed 22.5 11R Cummins Factory Exhaust Brake 8000 watt Quiet Diesel Generator 9608-M0022-38MI-4C Christened Midnight 1972 22ft 72081169MC22C Christened Camp Barth | |||

|

Official Barth Junkie |

Finished installing the left side.  The right side is easier to work on, there is more space on that side of the doghouse so you can reach everything on the engine easily from above. The three bolts on the flange are easier from below. You can even remove and replace the header from above!  Ooh, shiny new pipes! (Dang salt air is rusting my jacks already..)  Inspection of the right side revealed a surprise. This pipe was also cracked, soon to fail... Similar location to the other side. These pipes are about 10 years old with about 50k miles.   If you have Thorley headers of this age you may want to inspect the welds closely. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Official Barth Junkie |

I replaced the motor mounts when I did the crankshaft job. Torque rock is minimal. The system swings freely so I don't think it is being restrained. I may install springs on the flange bolts to allow some give but I don't think it moves much. One header was cracked near the front y, the other at the rear y. Both cracks started adjacent to welds. Not sure why but it will be interesting to follow through and see if any other similar failures occur. I'm wondering if the heat of welding changed the metal. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

6/12 6/12Formally known as "Humbojb"  |

I was involved in the specialty metal business for over 25 years. I don't know what the Thorley headers are made of. Some of them are 4130 alloy steel, others straight carbon steel. But all of the metal goes through a heat treating cycle when they are welded. Essential to all heat treating is a final tempering process to remove the stresses caused by heat treating, or in this case welding. In fact the best way to deal with welded joints is to anneal(soften) the entire assembly, and then reheat treat the entire assembly. Few companies have the expertise to do this. If the tempering process is not done properly, the stresses remain and the 'weld affected area', will eventually crack. My guess is that your headers may not have been properly tempered after welding(heat treating). And it may be an isolated incident, because there are many Thorley headers out there that have lots of miles on them with no cracking.

| ||||||||||||

|

Official Barth Junkie |

Improper annealing was what I was thinking since the cracks do parallel the welds. As you suggested, consistent annealing is not easy for large irregular pieces. There are indeed many sets of Thorleys out there, not sure how many are being regularly driven and how many miles. It will be interesting to see if others have failed this way. Now I can get to my other projects... 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| First Month Member |

There is always a stress riser where thin metal joins thick metal. And, of course, cracks often occur at stress risers. Agree on the heat thing, as well. Thorley used to have a lifetime warranty. Don't know about lately. . 84 30T PeeThirty-Something, 502 powered | |||

|

Official Barth Junkie |

They still do have lifetime warranty against defects...(fine print: original owner only, nontransferable, with original receipt...) Bro-in-law got these, not me, and we have no paperwork. I'm still happy to replace them with new... pick em up, you know they are stout. Bolt right in. This time, I will keep the receipt. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

6/12 6/12Formally known as "Humbojb"  |

The Thorley headers on my 85 Regal are 20 years old and no problems. Not even very rusty. Think mine were shiny black as new, but probably not porcelain.

| ||||||||||||

|

| First Month Member |

Mine were new in 2001, and were nickel. Now rusty, due to many years within a mile of the ocean. . 84 30T PeeThirty-Something, 502 powered | |||

|

Official Barth Junkie |

I think my headers were rusted badly due to road salt back and forth to Florida and salt air while here. It spent 12 years going back and forth from New York or New Hampshire and now Michigan, then sat all winter right on the edge of the ocean when my inlaws spent the winter here. The new ones are ceramic coated, I think that should help resist corrosion a bit better. It appears that Thorley makes all the 303Y with ceramic now, maybe they had enough corrosion problems with the plated ones. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

06/08 06/08 |

It is time for me to replace my headers also and was thinking of going with the later single exhaust setup. http://www.summitracing.com/pa...te-306y1-c/overview/ I was thinking the single system would help continue the scavenging effect the tri-y headers started and in turn give better low end toque. Staying with the dual would be easier and cheaper but if going to a single 3" would help this would be the time to do it. Any opinions on this any one? Neil. | |||

|

Official Barth Junkie |

I have dual headers going into single 3" exhaust. Some good discussion here: https://www.barthmobile.com/eve...1087061/m/5023993377 The second mufller made it much more quiet. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

| First Month Member |

I wrestled with this and went with Thorleys and an X pipe from Summit. I use fairly loud mufflers (afterburners), and side dumps, and the X pipe made the sound smoother and less offensive than either true duals or duals with an H pipe. . 84 30T PeeThirty-Something, 502 powered | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.