Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

10/10 10/10 |

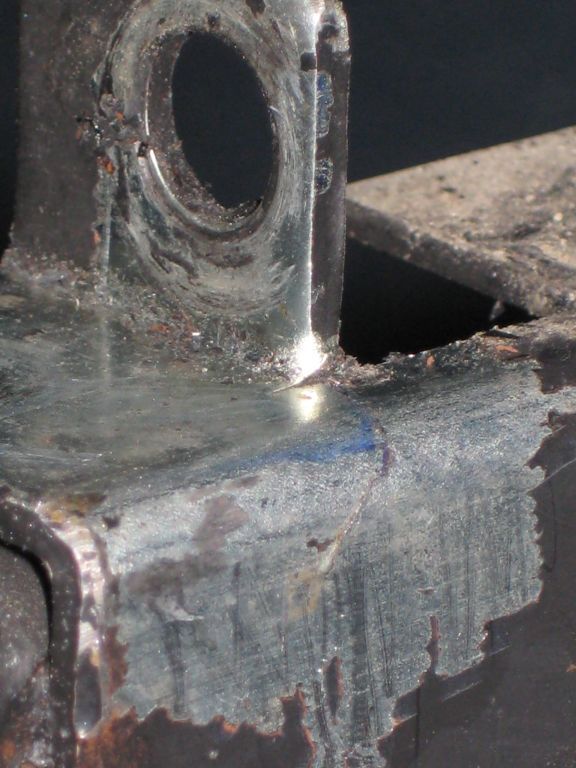

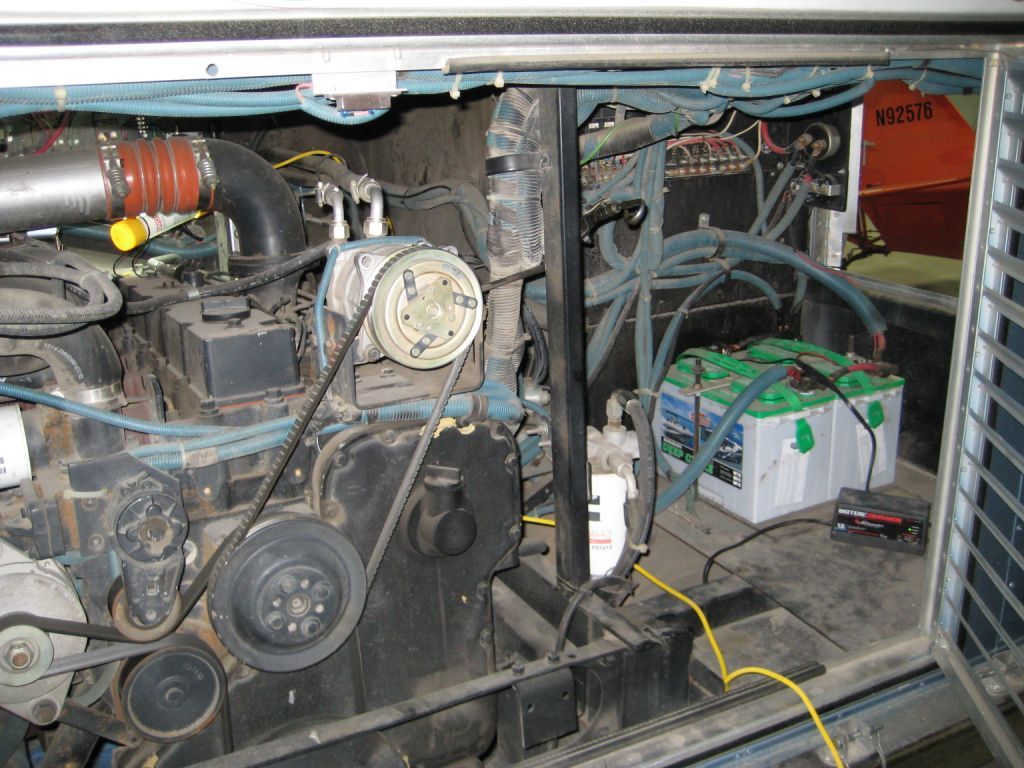

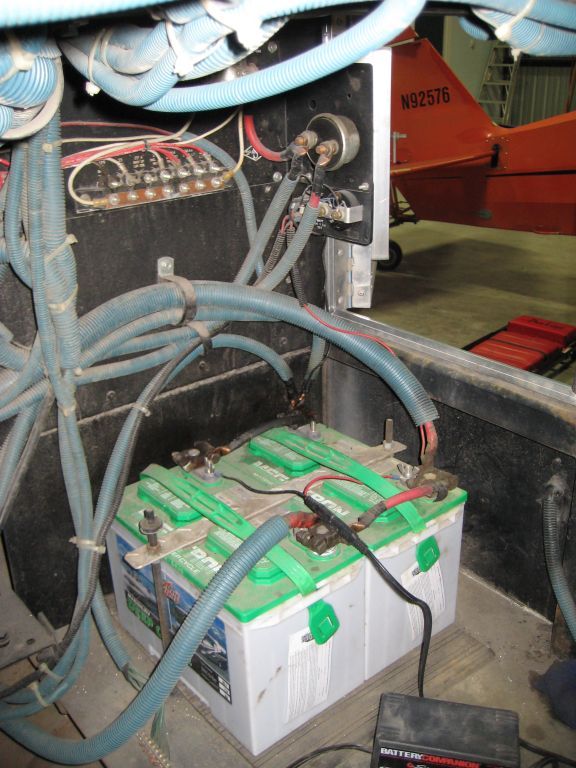

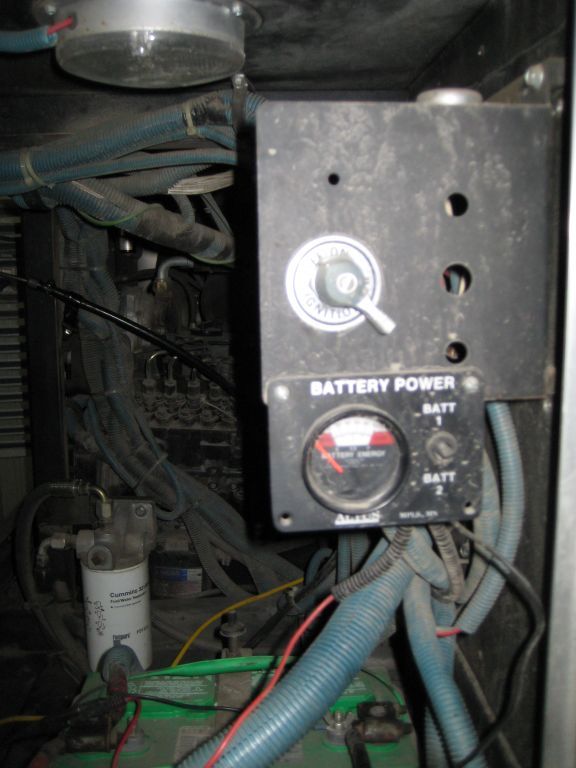

First off I have say to that I was mistaken when I thought that the 8D batteries in the slide out tray were the coach batteries, they are the chassis batteries. And to think that I was just about to replace them with Trojan golf cart batteries, whew! Are the chassis batteries normally on a slide out tray in a class A coach? So now I have brand new 8D chassis batteries and a cleaned and painted battery compartment. I also have several electrical issues that I'm trying to sort out. 1. It appears that someone wired the Allison VIM and ECU modules directly to the chassis batteries to solve a previous electrical problem or it was wired that way from the factory. In short, the Allison transmission controls are powered up 24/7 and drawing 2.6 amps from the chassis batteries. The on board trickle charger is rated for 1.5 amps max so can't possibly keep up with the load. I can't imagine why the VIM/ECU would be connected to a live power source and not a switched one. Does anyone have experience with this issue? 2. The chassis batteries are not charged when connected to shore power. It appears they are charged from the engine altenator only. Does this seem right to you guys? 3. There are 4 holes 3" to 4" dia. in the back wall of the chassis battery compartment. It's clear that the compartment must be ventilated but I was thinking about pop riveting some rubber flappers over the holes to help keep the grit and grime out. The flappers would be attached at the top only. Does anyone see a problem with this? The photos are of the chassis batteries on the slide out tray and the green marine coach batteries in the engine compartment. I tried to capture the cracked bolt tab that secures the tray but I'm not sure if it will come out. One tab was completely broken off and the other was just about to break off. I think that 260 lbs. of batteries on a sliding tray would have tore the compartment door clean off it's hinges under the right conditions, (like maybe a hard left turn).           1993, 34', Regency, Widebody 300 HP Cummins 6 spd Allison, Spartan Chassis | ||

|

The Allison ECU IS normally wired in for full time electrical power but should not draw that much power. The reason for this is that the Allison has a "learning" feature that will remember driver's habits and adjust the shift points accordingly. Any time the battery power is fully removed from the Allison trans ECU, the unit will reset and start learning all over again, it may shift funky until it re-learns your driving style. Again, it should not draw the power you recorded. Is the trans controller display lite when the key is off? If not, it probably is wired correctly but there may be other things that are drawing the power you recorded. Chassis batteries are not normally charged by shore power, I have added a separate smart charger for that purpose. I have monitored the charge and even with the Allison connected 24/7 on mine, the chassis batteries stay fully charged with the small smart charger. If the battery area is not vented and only the holes you mentioned are there for venting, I strongly recommend that you do not block these in any manner. Hydrogen gas is released during charging and can have disastrous results if a spark or source of ignition is present. An internal battery spark can also set it off. I would double check the main serpentine belt and tensioner!! From the picture it appears that the tensioner is very close to the end of travel. If it is, the belt will wear faster then normal, serpentine belts require a lot of tension to live Is that a tail of a Piper PA-12 I see in the background? Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

10/10 10/10 |

Thanks MWrench, I knew about the ECU's ability to learn and tune shifting patterns but I wasn't sure if it's memory was volatile or non-volatile. Thanks for the clarification. If that be the case then I agree that a 2.6 amps draw is way high, especially with the ignition key off. When power is applied to the VIM a relay energizes. I pulled the relay and powered back up but still had a 2.5 amp load. The ECU display lights up when the ignition switch is turned on so that works like it should and the transmission shifts just fine or at least it did the last time I had it on the road. It looks like I'll have to dig deeper into this electrical quagmire. I'm also going to install new smart chargers on the chassis and coach batteries. I'm looking that the PulseTech model 100X013 XC-Parallel. I will leave the holes in the battery compartment uncovered. I will also check my serpentine belt. Thanks for the input. Wow! You either checked my tail number in the registry or you have a lot of experience with old pipers. It is indeed a 1946 Piper PA12. And, like most cubs in Alaska it is setup for bush operation so the only standard thing about it is the model and serial number. It has extended wings, squared tail feathers, upper and lower baggage, supercub landing gear, weld-on float fittings 160 HP, big prop, 1935 gross weight increase and a few other mods. I fly it back and forth to work and also hunt, fish and explore with it. I found it pushed back into the woods in North Pole, Alaska. The owner had retired and moved down South so he left it with a friend to sell for him. By the time I found it several families of squirrels had moved in, the bunges had rotted and the top of the wings and fuselage were black from birch tree sap. After two days of cleaning, draining fuel tanks, changing oil and tying the landing gear together with rope so it wouldn't splay out on me I took it on it's first flight. It flew like a dream. That was in 1992. I rebuilt the engine 3 years ago and the airframe is supposed to be rebuilt this winter. This is it in the hangar.  1993, 34', Regency, Widebody 300 HP Cummins 6 spd Allison, Spartan Chassis | |||

|

3/11 3/11 |

With considerable experience on my 1993 32 Regency I can't believe your battery arrangement. I have almost the identical setup and the tray is four Trojan deep cycle house batteries. The tray in the engine compartment holds two 8D chassis batteries. Trace the major connection from the engine compartment and see if the main cable goes around the engine to the starter via the starter solenoid (mounted on the engine compartment wall). There is little sense in locating these opposite to virtually all other Regencies. As for the little tabs on the tray I had 1/4" angle steel welded to the tabs and the tray to fix this. They are way to flimsy to secure the batteries against normal road jounce and turns. You don't want them missing - doors and cables aren't cheap. 1993 32' Regency Wide Body, 4 speed Allison Trans, Front Entry door, Diamond Plate aluminum roof & 1981 Euro 22' w Chevy 350 engine and TH 400 tranny | |||

|

I was stationed at Eielson AFB in the early 60's and flew mercy missions out of Fairbanks for Halley Evans when off duty with the USAF. I have flown a few PA-12s, Learned to fly in a J-3 and then on to a C-170A. Recognized the PA-12 by the horiz stab trim. My former C210A is at Anchorage Merrill field, tail# N9525X Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

10/10 10/10 |

Tom K, My thoughts exactly. Why would anyone put chassis batteries in the slide out tray but that is exactly what was done. During my 2 days of electrical troubleshooting I traced every wire and cable connected to both sets of batteries. The 8D's in the slide out compartment are clearly connected directly to the engine starter. The green deep cycle marine batteries in the engine compartment feed the coach load when the house solenoid contactor is energized. When the solenoid is de-energized the 12 vdc house power comes from the 75 amp charger, assumming of course that the you are plugged into shore power. I made a sketch of my 12 volt distribution circuits and am not impressed. I think my electrical might need a bit of updating. With regard to the sliding tray tabs, yes they are pretty flimsy. My plan was to replace the slides with heavier duty stainless steel ones. That is until I discovered that the existing ones were welded in making them a major pain to get out. In the meantime I did a weld repair using 4130 filler rod. Thanks for the input 1993, 34', Regency, Widebody 300 HP Cummins 6 spd Allison, Spartan Chassis | |||

|

3/11 3/11 |

The only reason I can think of is the considerable problems with changing the big 8D's. When I had mine replaced the shop used a fork lift after removing all the air cleaner assembly. Far too heavy for the normal Seasoned citizen. But I would change them back anyway - it just ain't natural! 1993 32' Regency Wide Body, 4 speed Allison Trans, Front Entry door, Diamond Plate aluminum roof & 1981 Euro 22' w Chevy 350 engine and TH 400 tranny | |||

|

1/11 1/11 |

I KNOW YOU DON'THAVE ENOUGH RED WIRES LENNY lenny and judy 32', Regency, Cummins 8.3L, Spartan Chassis, 1992 Tag# 9112 0158 32RS 1B | |||

|

10/10 10/10 |

After much fiddle farting around with Allison tech support I got the information I needed. Long story short!...........The 2.6 amp load on the dedicated power wires to the Allison ECU and VIM is indeed way high as I suspected and MWrench confirmed. Allison says a few milli amps is all you will see with the ignition off. To isolate where the load was actually coming from I pulled the connectors off the ECU, inspected the cables and connectors then reinstalled them after not finding any problems. Started the engine and shifted into 1st and reverse several times with no problems noted. Checked the current in the power circuit and low and behold it was now 4.23 milli amp. Cycled power several more times but the load current with the ignition off stayed at 4.22 to 4.27 milli amps. I didn't find the smoking gun so this problem may rear it's ugly head down the road, probably when I least expect it or need it. Thanks to all for your input. Roman 1993, 34', Regency, Widebody 300 HP Cummins 6 spd Allison, Spartan Chassis | |||

|

9/09 9/09 |

You may have the answers to a couple of questions I have been seeking. 1. What is the V.I.M. and where is it located? 2. Where is the ECU located? I have a 1993 38 ft Regency. I also do not have the disconnect, etc. you do. I hope you can help me out. Lance & Sue Walton Previous owner of a 1993 38ft Regency Cummins 6CTA8.3 300HP Allison MD3060 Transmission Spartan Chassis Loveland, CO | |||

|

FKA: noble97monarch 3/12 3/12 |

Lance, Saw this article that explains the VIM function and shows location on an Allison 300. May help. http://www.mechanicshub.com/me...c-transmission-.html What type of issue are you having?  Formerly: 1997 Barth Monarch Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited, “I haven’t been everywhere, but it’s on my list.” | |||

|

Interesting article. Our 2000 series allison has no VIM. Also the refer to the transmission control unit as a TCM probably to save confusion as almost all were sold behind an Electronic controlled engine or ECM. My TCM will comunicate directly to the ECM if one exists. In my case there is no ECM but a TPS (throttle position sensor). '92 Barth Breakaway - 30' 5.9 Cummins (6B) 300+ HP 2000 Allison Front entrance | ||||

|

10/10 10/10 |

Lance, The VIM for my 1993 Regency is located on the ceiling of the electrical bay (left front of coach). It is a black box about 7 inches square and 2 to 3 inches deep and has 2 bundled wire connectors attached to it. The ECU for my MD3060 is located under and attached to the electronic shifting console. If you haven't already done so try to located your transmission computer interface connector. It is about 1 1/2" long by 1/2" high and 1" deep, mine was light gray in color. It should also be in the electrical bay, probably behind or buried inside the large bundle of wires. Mine was very difficult to find, took me over an hour to find it. The Allison tech looked for probably 20 to 25 minutes and couldn't find it and his supervisior looked for about 10 to 15 minutes in all the common locations and didn't find it. Once you locate it identify it so it's easier to find next time. Roman 1993, 34', Regency, Widebody 300 HP Cummins 6 spd Allison, Spartan Chassis | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.