Page 1 2

Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

Been pretty slow on the site lately. Just to let you know, I am working on some things. Many large upscale commercial engines have pre oiler systems to prime and pressurize the oil system prior to starting. I have always felt this was a very desirable feature. After an engine is shut down, the oil in the engine continues to slowly drain back down into the oil pan. If the engine is not restarted again for an extended time, the engine oil system drains back as well. The result is that the next time the engine is started, there will be a delay before oil is supplied to all parts of the engine. Good example is the turbocharger. It sits high on the engine and has its own oil supply lines. When they drain down it takes a short time to get the oil flowing to the turbo. This delay in lubrication, with no oil flow, combined with cold engine temperatures can cause wear in the first seconds of operation. Dry bearings, cam lobes, etc clattering around for even a few seconds does them no good. Unfortunately, the average coach engine often sits for extended periods between starting. Mine is no exception. Enter the preoiler system. The system is designed to pressurize the entire engine oil system prior to starting. This eliminates the possibility of dry bearings, turbo, cam lobes, etc. Some store pressurized oil from the last engine run, others have external oil pumps to supply oil to the main engine oil galleries in the block. MWrench confirmed the value of preoilers. He has already built a system for his 5.9 Cummins. I started collecting parts for my system. So the other day I was getting ready to change the oil. The engine was grubby and long overdue for cleaning and painting. I did notice the extra plug on the side of the oil pan.  | ||

|

Official Barth Junkie |

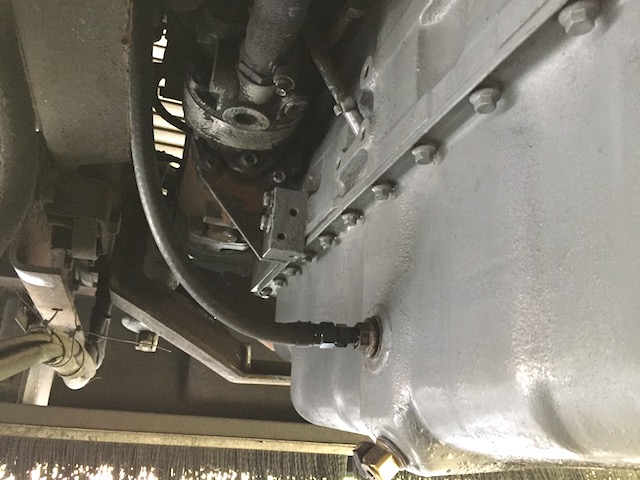

Looked up a bit higher on the block... There are some oil pressure senders up there..  | |||

|

Official Barth Junkie |

Decided to clean things up (long overdue) and have a better look. | |||

|

Official Barth Junkie |

Interesting. There is an internal oil gallery running through this side of the engine block. There are two oil pressure senders installed there. One is being used for the panel gauge, the other is left from a long gone preheater system and is idle. So this presents a couple good options. The oil plug on the side of the oil pan is intended for use for an oil pan heater. This could be a good place to pull oil from the pan for the preoiler system. Meanwhile, the output from the pump must be returned to the main oil galleries in the engine oil system. Ideally, this would return the oil via the oil filter, to ensure no dirt can get back to the engine. Unfortunately, the oil filter on this engine is on the opposite side, requiring a rather long return line. The other option, since the oil galleries are on the same side as the pan plug, is to install a small filter in the return line, then connect this line directly into the gallery, without worry of contamination. This would allow a short return line to the engine block, replacing the sender at the top right. | |||

|

Official Barth Junkie |

Meanwhile, looking at the top side of the engine, there is a shelf above the frame on the pass side. At the far end is my high end "coolant recovery tank" In front, there is room for the pump. It is then close to both the intake and return ports. There is room on the wall on the left to mount the oil fiter. This is looking good. | |||

|

Official Barth Junkie |

I think I have most everything ready: Top left: Derale Oil Filter Mount #25709 1/2 NPT to AN6 fittings Top right: 1/4 check valve with AN6 and 1/8 reducer fittings, oil pan to AN6 adapter lower left: tilton oil cooler pump 40-527 3/8 NPT to AN6 fittings lower right: 3/8 transmission cooler hose Soon to be installed | |||

|

7/17 7/17 |

When I use to own stock cars we use to have a system that use an a accumulator that had a bladder that would be pressured with oil pressure. With engine running oil pressure would fill the accumulator pressuring bladder. A valve would be opened to allow the oil into the accumulator. This would allow pressured oil to feed into the engine when going into turns to prevent oil starvation. Before shutting engine down the valve would be closed keeping pressured oil in the accumulator. Before starting the engine the valve would be opened allowing pressured oil to pre-lube engine. With a solenoid to shutting off oil going to the accumulator under pressure and turned on before starting up should achieve what you looking for. accumsump 1986 31' Regal -1976 Class C 454/T400 P30 -350/T400 G30 twin cntr beds - 21' rear bath | |||

|

I also have used Accusump on my track cars. Very nice insurance against momentary loss of oil pressure. For preoiling the diesels I found that the capacity of the accusump not enough for adequate oiling prior to or during cranking. The pick up tube to the engine oil pump is long and it takes a good 10-15 seconds to build oil pressure after engine has started. With the electric preoiler pump I can build 20 lbs of pressure before cracking and the engine oil pump is pre-primed by the preoiler so engine oil pressure goes immediately to 80 lbs upon starting. The other issues with a diesel engine is priming the fuel system. Long cranking times are generally needed. Of course long times between use are common on RVs. MY Breakaway has 330K miles on it and I am in the middle of an inframe overhaul, bearings looked very good. During the last 15 years of ownership it doesn't sit for long periods of time. I have had the preoiler on mine for the last 50K miles. When the overhaul is finished, I will run the preoiler and slowly turn over the engine from the damper to insure everything has an abundant amount of oil before starting. I am oiling all parts during rebuild but because it is an inframe overhaul there are some rotating parts that will not have good oiling at first start. Ed 94 30' Breakaway #3864 30-BS-6B side entry New Cummins 5.9L, 375+ HP Allison 6 speed Spartan chassis K9DVC Tankless water heater | ||||

|

7/17 7/17 |

Thanks Ed. Not knowing how pre oilers work I just thought it may be an option. I believed that accusump was cheap insurance. 1986 31' Regal -1976 Class C 454/T400 P30 -350/T400 G30 twin cntr beds - 21' rear bath | |||

|

Official Barth Junkie |

I believe sump systems were used in several European auto models. Volvo used them and I believe Saab did also. They work well on smaller engines. Larger industrial generator and equipment engines often use preoiler pumps. I will get back to the installation and report the progress... 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

This is a real good idea Steve. Thanks for undertaking this and I look forward to seeing your updates. As you know I also have a 1978 GMC motorhome that I have owned since 1982, and restored a couple of times. I replaced the 403 old's engine a long time ago with a 500 Caddy because of the added torque. I have always been concerned about start up because it sits for such long periods, like over the entire winter, so I am thinking about a pre oiler for that as well. Oh, and one other thing, how in the world did you get the engine pan and block so clean? Wow, that looks new. Bob & Yvonne 1997 Monarch 38 Spartan MM, 6 speed Allison Cummins 8.3 300 HP 9610-M0027-38MI-4C | ||||

|

Official Barth Junkie |

Yeah, as in new paint! The good news, the engine does not leak. Bad news, it is rusted and dirty. In the areas without grease, I just use a scraper for the big stuff, then a wire brush. I rinse with a little carb cleaner and a rag, blow off and paint. For greasy areas, I power wash if possible. I use a stiff brush and fuel oil until most of the heavy stuff is gone, then wire brush and rinse. I always paint with a brush when I can, at least the base coats. Spray doesn't work into pits and corners that well. As I get time, my goal is to get the engine and engine bay repainted. Between years of road dust, carbon from a leaking exhaust manifold, and rain slop they need it. It has another bonus: As I am doing this I find "wonder" wires and lines. (I wonder what that's for...?) I just drained the oil so I can start intalling the preoiler lines and fittings. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

Official Barth Junkie |

So back to the project. I drained the oil and changed the filter. With the pan empty I removed the upper plug only to see the turd fairy! The upper pan plug is not the same size as the drain plug... The drain plug is M18 thread while the upper plug is M22. I do not have a M22 to AN6 adapter lying around and it will take a week to get one! OTOH, I have the plug, a 7/16 drill, a 1/4NPT tap, and a 1/4NPT to AN6 fitting. A while later I had the adapter finished.  | |||

|

Official Barth Junkie |

Now I can install the plug and attach the suction hose, then run it up to the pump.  | |||

|

Official Barth Junkie |

I mounted the pump and filter on the shelf above the frame. The pump is just where it should be. I would have preferred the filter more to the right but behind the panel are electrical circuit breakers and wiring, with no good place to drill holes. I used an existing bolt on the left. Since the system only runs for a short period each time, I used a smaller filter (Wix 51348 = CarQuest 85348) to save space. Also used street ell fittings on the pump for the same reason. The suction hose from the pan goes along the right side of the pump, then a hose from the pump to the filter, then another from the filter back to the engine block, via a check valve.  | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.