Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

Official Barth Junkie |

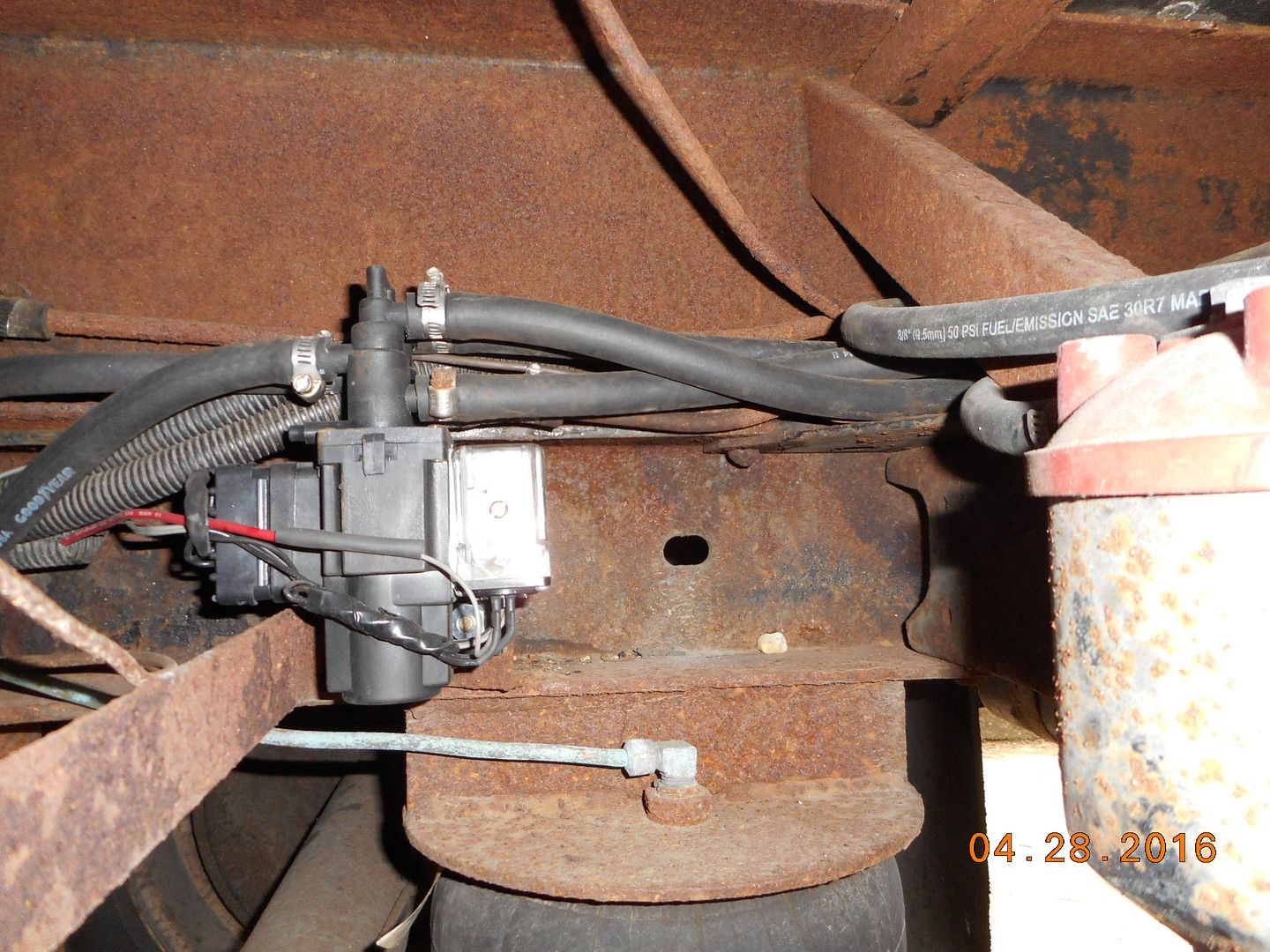

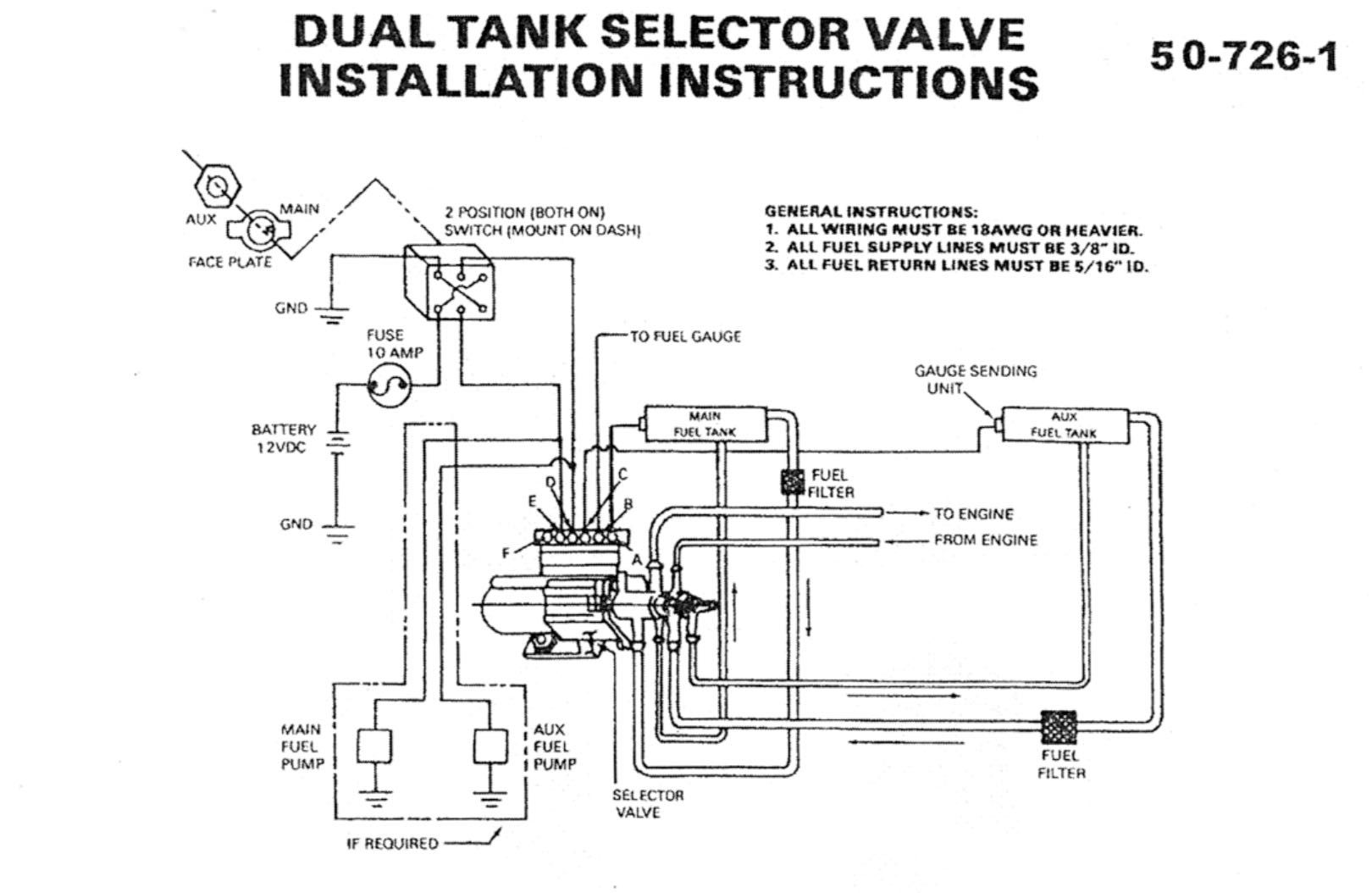

During the 70's and 80's GM made several changes to the dual fuel tank setup. Early versions had the 3 port fuel tank selector valve and mechanical engine pump only. These were subject to vapor lock problems. Early 80's they added a frame mounted rear electric boost pump. By mid 80's they had evolved to a 6 port valve with intank electric pumps and fuel return lines. Here is one from an old thread on Jim and Tere's coach.  I have replaced 2 of these valves, GM 467513. They were one wire solenoid type valves. With no power applied, the spring pushes the plunger to one end and opens the ports to tank 1. With power to the terminal, the solenoid magnet pulls the plunger to the other end to open ports to tank 2. 2 problems: the valve fails quickly and they are no longer available. I suspect that ethanol may have swelled the orings and made the valve stick. These valves originally date back to pre alcohol fuels. Both of mine eventually failed to transfer and ended up stuck, with fuel flowing to/from either tank. There is a similar valve widely used in modern applications. Standard FV5 has the same mounting flange and fuel hose layout as the old GM version. This valve is motor driven to force the plunger in either direction reliably.  GM 467513 left------------------Standard FV5 right. Unfortunately, the motor requires 2 wires to operate and the polarity of the wires must be reversed to transfer the valve. (It also has 3 other wires used to switch the fuel gauge wire to the appropriate tank fuel sender, if needed) Physical installation is easy. New valve bolts into same holes as old one. Fuel lines attach to the same valve ports, no trimming/fitting needed. Electrical requires some more work… The original valve defaults to tank one and only gets power when tank 2 is selected. New valve needs two wires with constant power, but they must be reversed to transfer the valve. 2 options: install a double pole single throw switch in the dash panel and run a second control wire all the way back to the valve. Or, mount a double pole relay near the valve. Feed power and ground from the nearby fuel pump (energized whenever the fuel pump is running) to the relay. Trigger the relay with the existing selector wire. When the relay is not energized, the power wires go to the valve and select tank one. When the relay is energized the wires to the valve are reversed and tank 2 is selected. If you are replacing the old valve with a new one, you will need the harness to fit the plug. Order FV5K (the kit contains the harness plug and DPST switch.) Before: (so that's where that hose clamp went…)  After:  I epoxied the relay to the side of the valve. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | ||

|

|

Thank you for this post! I have a 1977 Chevy K10 and am switching to EFI so I need to change from a 3 port valve to a 6 port valve to support the return lines. The current valve is a one wire and as you know the 6 port / 1 wire valves are hard to come by. I want to use your solution of a relay to bridge that gap. Do you have a part number or specifics as to which relay to get? Any additional details about the wiring you can share? I really appreciate your expertise! | |||

|

Official Barth Junkie |

As you know the old valve only needed one wire. That valve has a coil which pulls the valve against an internal spring to change tanks. When the wire was not energized, the spring held the valve in the tank 1 position. When the selector switch was set to tank 2 the wire energized the coil and moved the valve to tank 2 position. The new style valve has a small reversible motor which moves the valve from one side to the other. The motor has two wires. Depending on the polarity of the wires, the motor runs in one direction or the other. The purpose of the relay is to provide reversible connections to the motor. When the relay is energized, the polarity of the wires is reversed and the motor moves the valve to the other tank. You will need a source of switched power for the valve motor. (Ignition circuit/fuel pump circuit) The relay has a 12V coil which is connected to the original wire from the selector switch. When energized, the relay reverses the power connections to the valve motor. You will need a 2 pole continuous duty relay, 12v coil, contacts rated at least 3 amp.  Hope this helps. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

This definitely helps. So basically I'll only be using 2 of the 5 wires from the new valve's dongle. One would be the current wire that powers the current one wire valve and one would be ignition/pump power (from the pump for example). You provided the specs for the relay which is great. Do you remember which wires from the new dongle were used for the switch wire and the ignition/pump power wire? Do you have any links for a relay that would work for this application? Thank you very much for your help. My fingers and ears hurt from calling trying to find the OEM part!! | |||

|

Official Barth Junkie |

I found a diagram of the valve wiring setup. Basically, the relay takes the place of the criss-cross dash panel selector switch so you can leave your one wire OEM selector switch.  It looks like the wires to the valve motor are the two next to the empty hole on the end... (D and E on the diagram) 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

Thank you! I've been searching for an appropriate relay. I've tried electric suppliers and auto parts places locally. Do you have a link or part number you can share for one that would work for me? | |||

|

Official Barth Junkie |

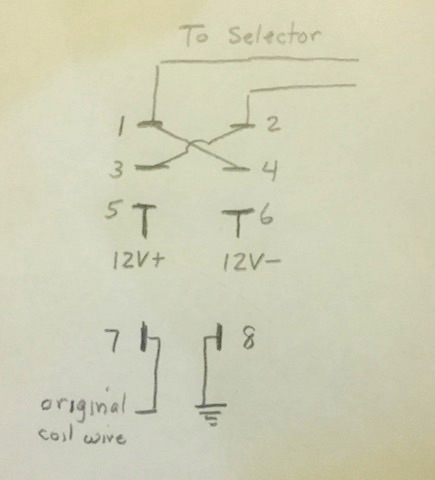

Something like this should work: With mounting brackets: https://www.amazon.com/uxcell®...-Power/dp/B008MU0MRQ The purpose of the the relay is to provide reversible power to the selector valve. 12V + and - are connected to the common terminals, 5 and 6. Terminals 1 and 2 are connected to the selector valve wires. Terminal 1 is also cross connected to terminal 4. Terminal 2 is cross connected to terminal 3. In the resting position, 12V+ goes from terminal 5 to terminal 1 and out to the selector. 12V- goes from terminal 6 to terminal 2 and out to the selector. (terminal 1 is + and terminal 2 is -) When the relay transfers, 12V+ goes from terminal 5 to terminal 3, then crosses over to terminal 2 and out to the selector. 12V- goes from terminal 6 to terminal 4, then crosses over to terminal 1. (terminal 1 is now - and terminal 2 is now +) Whenever the wires are reversed the selector valve motor runs and drives the valve from one end to the other, changing fuel flow from one set of ports to the other. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp  | |||

|

|

Thank you very much for all your time and knowledge! | |||

|

Official Barth Junkie |

No problem, I hope it all works out! By the way, welcome to the Barthmobile site. Not sure how you found us, but we have a pretty good collection of tech subjects and people who can often help. Take care. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

Found this post while googling for hours about options due to the OEM valve not being available. Yours seems like the best option to use while not having to do a major rewire and switch swap. Greatly appreciated! Hopefully others will benefit from the additional details you were kind enough to provide. Cheers! | |||

|

Official Barth Junkie |

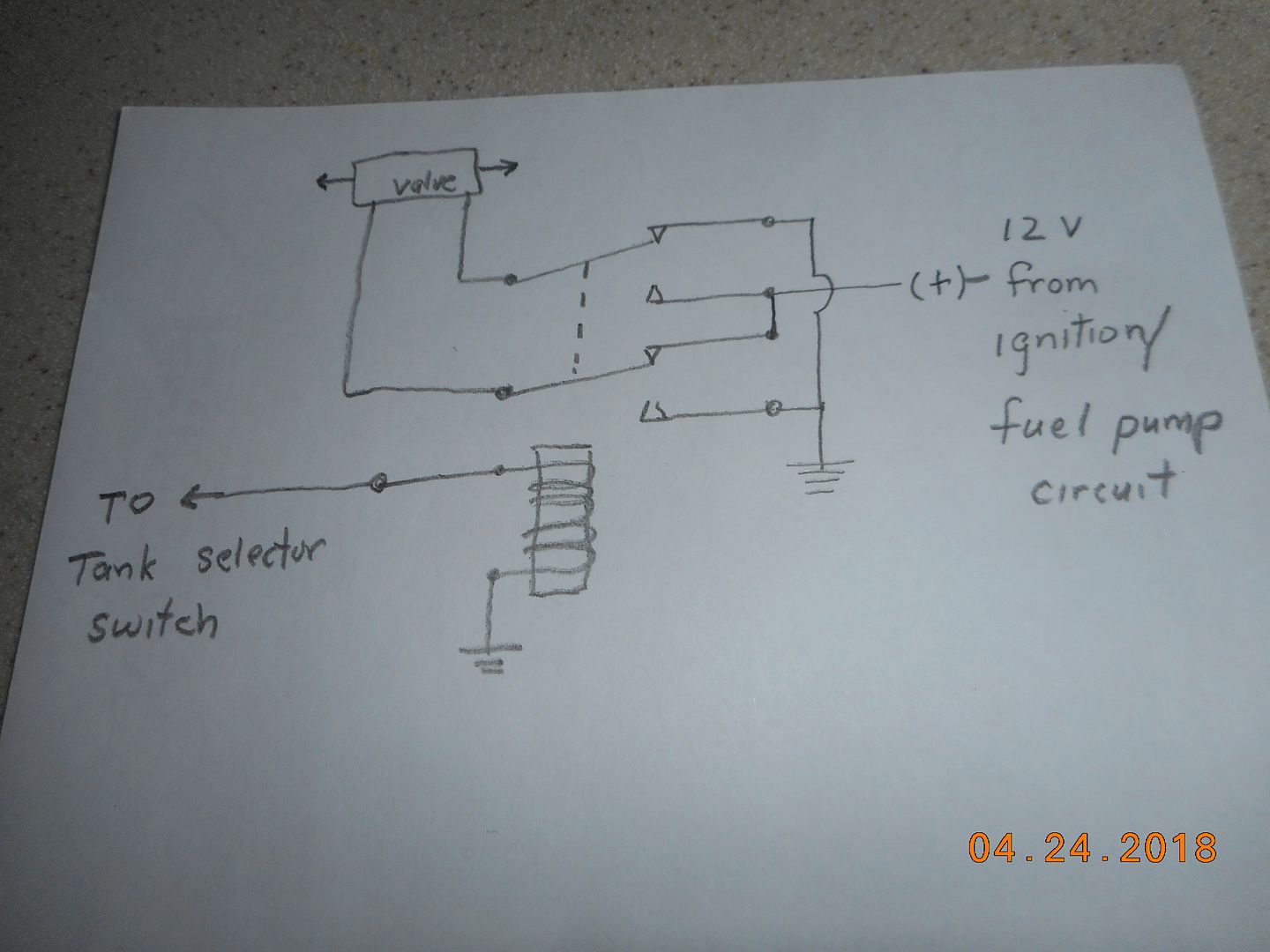

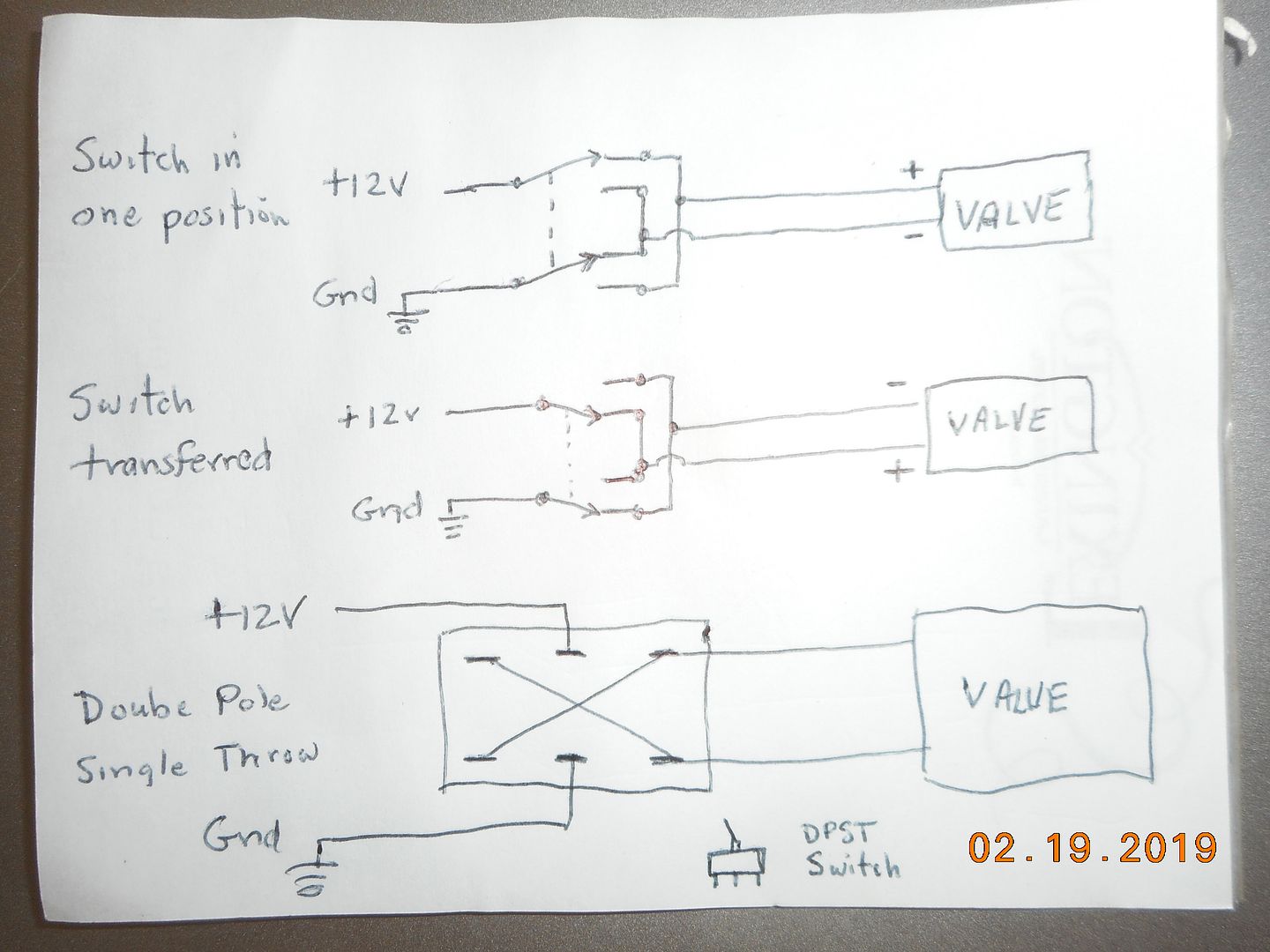

I had another question a while back about the wiring. If you don't mind running a pair of wires from the dash to the selector valve you can eliminate the relay completely. (The only reason I used the relay was to be able to use the existing one wire switch in the coach panel.) If you run a pair of wires from the dash to the selector valce you can just use a double pole single throw switch. Here is my crude drawing for wiring a switch.  9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

|

This may or may not help but I recently changed my fuel system to support a Sniper EFI conversion on my 77 with in tank pumps. Below are all of the part numbers and some notes. 2 - ACDELCO EP381 {#25163473} (Pumps) - $57.79 ea. 2 - SPECTRA PREMIUM GM11C {#471681} (Tanks w/ Lock Rings) - $76.69 ea. 1 - SPECTRA PREMIUM FG05N {#25090837} (Passenger Side Sending Unit) - $73.79 1 - SPECTRA PREMIUM FG05M {#19179694, 25090846} (Drivers Side Sending Unit) - $66.99 1 - ACDELCO U7001 {#12336291} (Fuel Selector Valve) - $77.79 1 - STANDARD MOTOR PRODUCTS DS1807 {#15599081, 19244972, D7089C} (Tank Selector Switch) - $9.37 2 - Filler hoses to fit 1987 tanks - Can't find the part number Notes: Had to make a slight modification to reduce the 87 filler hose to the 77 filler neck Used the sniper pump power lead to power the switch so my selected pump only runs until prime is finished before I start it up Had to make modifications to the back of the selector switch to fit in the dash and be flush Shouldn't have purchased the full Sniper kit as I'm no longer using the inline pump Looks completely stock | |||

|

I hate to necro a thread, but here is some useful info. I just helped a customer sort this out. Thanks Steve VW for your excellent posts. Good relay for the conversion to the 6-wire (ACDelco U7000 or equivalent): #T92S11D22-12 This relay is sealed, but if you are going to mount it exposed use some quality shrink terminals and liquid tape. Connector body: #12015799 Terminals 16-14 ga: #12124582 Seals: #15324982 Cavity plugs: #12010300 You can get them all at Mouser, DigiKey, Newark etc. Best of luck, Alex Van's Electrical Systems Indianapolis, IN | ||||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.